Eigenschaften

Anwendungen

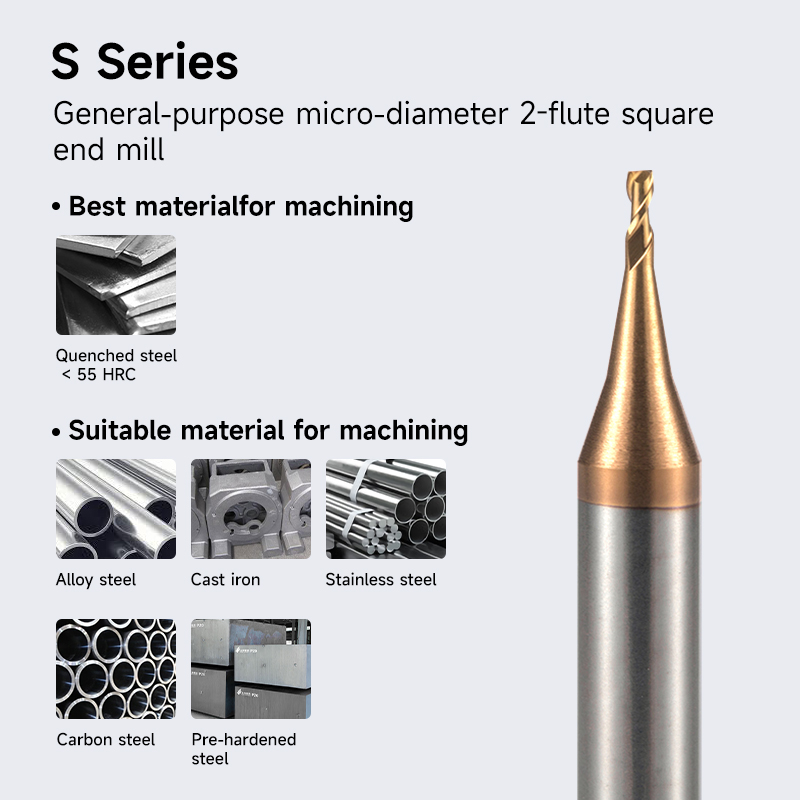

Arbeitsmaterialien

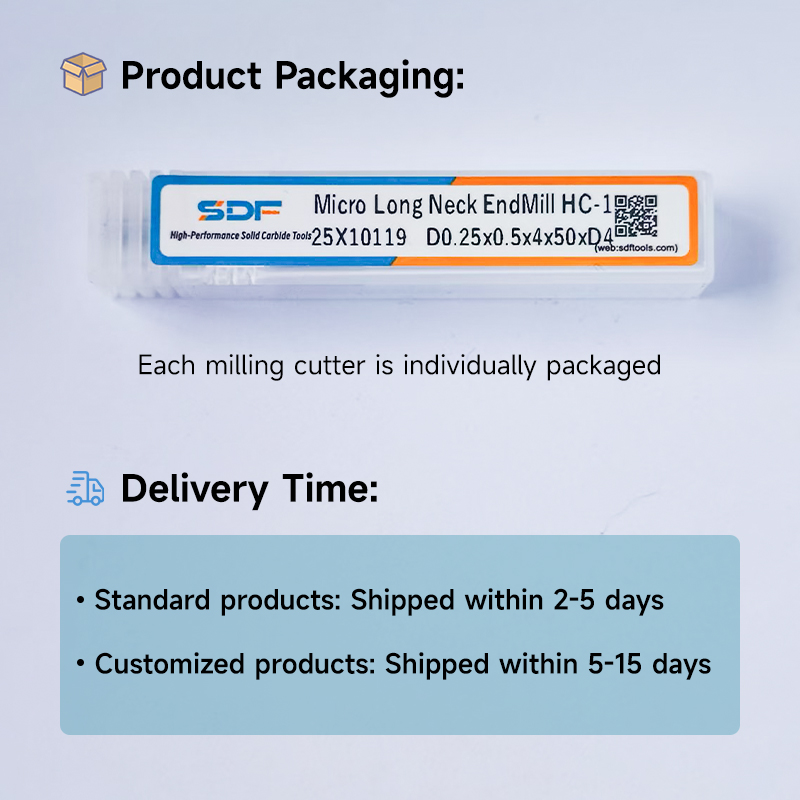

SDF-S Series Solid Tungsten Carbide Micro-Diameter 2-Flute End Mill – HELICK Coating

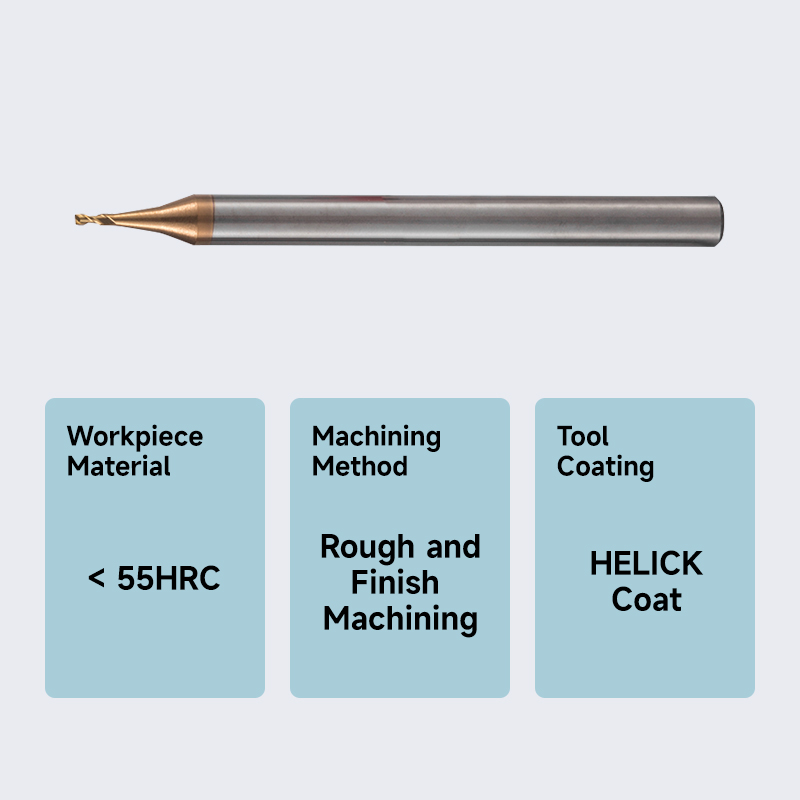

1. Material and Hardness:

This end mill is manufactured from high-quality solid tungsten carbide, ensuring exceptional hardness and wear resistance. The material maintains superior performance under high-intensity and high-speed cutting conditions, making it particularly suitable for machining hardened steel materials with a hardness level of HRC55. Even when processing extremely hard materials, the SDF-S series end mill provides stable cutting performance over extended periods.

2. Advanced Grinding Process:

Through advanced grinding processes, the SDF-S series end mill achieves ultra-high precision in both flute diameter and shank diameter. Each cutting edge is meticulously controlled to ensure micron-level accuracy and consistency, meeting the high-precision requirements of precision mold and component machining. This high precision not only enhances machining quality but also reduces the need for post-processing, improving production efficiency.

3. Fillet Transition Structure Design:

The fillet transition structure design of the SDF-S series end mill enhances the tool’s resistance to breakage and fracture. This design effectively reduces stress concentration, lowering the risk of fracture during high-stress cutting operations. Therefore, this end mill is particularly suitable for prolonged continuous machining of hardened steel materials, ensuring stable and reliable cutting performance.

4. High-Performance HELICK Coating:

The surface is coated with high-performance HELICK coating, offering superior wear and heat resistance, significantly improving cutting performance and tool life. The HELICK coating effectively reduces cutting temperatures, minimizing thermal deformation of both the tool and workpiece, and enhances the tool’s anti-adhesion properties, preventing chip build-up on the tool. Especially in high-temperature and high-pressure environments, the HELICK coating provides additional protection, making it ideal for machining high-hardness materials.

5. Two-Flute Design and Its Advantages:

The two-flute design provides efficient chip evacuation, reducing cutting forces and increasing cutting speeds, making it especially suitable for high-efficiency machining in micro-diameter applications. This design not only increases metal removal rates but also ensures a smoother cutting process, reducing vibration and noise, and improving machining accuracy and surface finish. For micro-diameter end mills, the two-flute design balances strength while minimizing cutting forces, ensuring long tool life and stability.

6. Application Range:

The SDF-S series micro-diameter end mill finds extensive application in various high-precision machining fields, particularly where micro-diameter and complex geometries are required. Specific applications include:

- Precision Mold Manufacturing: Used for machining fine structures such as mold cavities and templates, ensuring rapid material removal and achieving high-precision surface finishes, meeting the strict requirements of mold manufacturing for accuracy and surface finish.

- Luft- und Raumfahrt: Suitable for machining high-precision and reliability-critical components such as turbine blades, structural parts, etc., ensuring precise and stable machining of complex geometries. For example, machining micro-slots and holes on turbine blades.

- Automobilherstellung: Widely used in the precision machining of automotive components such as engine blocks, transmission housings, fuel injection system components, etc. These components have stringent requirements for thread quality and precision, and the SDF-S series end mill ensures high-precision and high-quality surface finishes, meeting the stringent standards of the automotive industry.

- Electronics Manufacturing: Used for machining micro-components such as semiconductor chip packaging, connectors, etc., ensuring high-precision and high-quality surface finishes, meeting the demands of the electronics industry for fine machining.

Medical Device Manufacturing: Used for manufacturing medical implants and other high-precision medical devices such as surgical instruments, orthopedic implants, etc., ensuring these components possess extremely high precision and surface finish, meeting strict biocompatibility and functional requirements.

Bewertungen

Es sind noch keine Bewertungen vorhanden.