Eigenschaften

Anwendungen

Arbeitsmaterialien

SDF-G-SUS Series Stainless Steel General Purpose 4-Flute Radius End Mill

Product Design

SDF-G-SUS Series Stainless Steel General Purpose 4-Flute Radius End Mill is a high-end cutting tool specifically designed for roughing and semi-finishing of stainless steel materials. Key design features include:

- Multi-Purpose Design: This series of end mills is suitable for both roughing and semi-finishing of stainless steel materials, catering to different stages of the machining process.

- Optimal Hardness: The tool hardness reaches HRC 45°, ensuring wear resistance and toughness for high-hardness material processing.

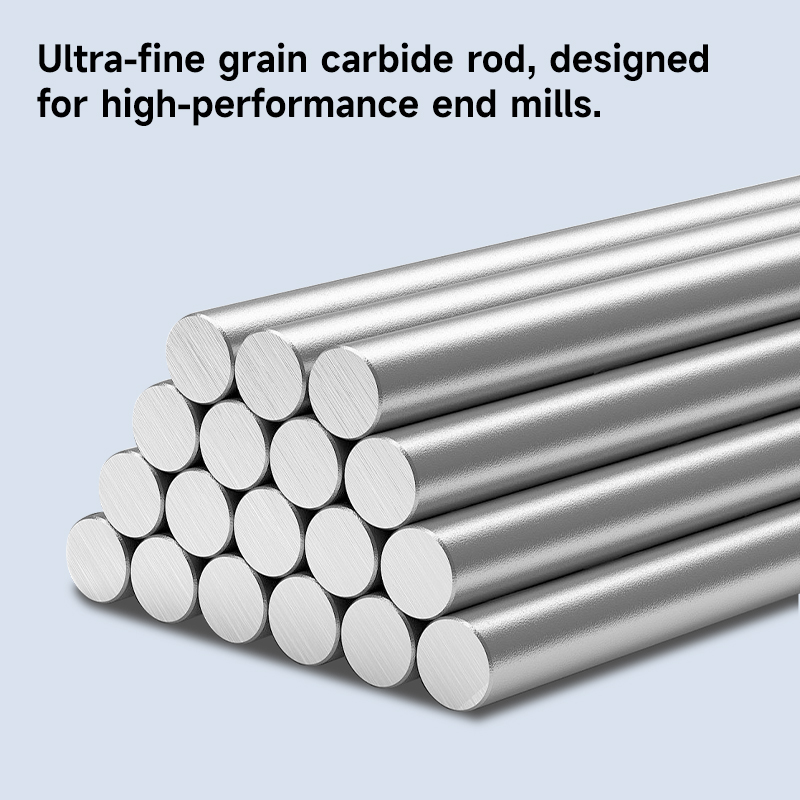

- High-Quality Material: Made from fine-grain tungsten carbide bar stock, which provides excellent strength and stability.

- Advanced Coating: Utilizes advanced Balzers coating technology, significantly enhancing the tool’s heat resistance and wear resistance, thus extending its service life.

- Unique Four-Flute Design: The distinctive four-flute design increases the number of cutting edges, improving cutting efficiency and surface finish, particularly suitable for high-efficiency and high-precision roughing and semi-finishing operations.

Product Advantages

- High Cutting Efficiency:

- The combination of the four-flute design and advanced coating technology increases cutting speed and efficiency, reducing machining time.

- Ideal for high-volume production and high-efficiency machining environments.

- High Precision Machining:

- The fine-grain tungsten carbide bar stock and HRC 45° hardness ensure high precision and stability, making it suitable for roughing and semi-finishing tasks that require high surface quality and dimensional accuracy.

- Appropriate for precision machining and high-precision applications, such as in the aerospace and electronics industries.

- Long Service Life:

- The advanced coating technology and high-quality materials provide a longer tool life, reducing the frequency of replacements and lowering maintenance costs.

- Suitable for continuous long-term operations and high-load working conditions.

- Low Maintenance Costs:

- The high cutting efficiency and long service life minimize downtime and maintenance costs, improving overall production efficiency.

- Ideal for production lines that require stable and continuous operation.

Anwendungen

- Stainless Steel Machining:

- Suitable for efficient roughing and semi-finishing of various stainless steel materials, such as 304 and 316.

- Widely used in the manufacturing of stainless steel products, including kitchenware, medical devices, and chemical equipment.

- Formenbau:

- Provides high-precision and high-surface-quality roughing and semi-finishing results in mold manufacturing.

- Suitable for the initial processing of precision molds and complex-shaped molds.

- Aerospace Industry:

- Suitable for the roughing and semi-finishing of high-performance materials in the aerospace industry, where high precision and reliability are required.

- Used for the preliminary processing of critical components such as aircraft parts and engine components.

- Automobilherstellung:

- Meets the high-efficiency and high-precision roughing and semi-finishing requirements in the automotive industry.

- Suitable for the initial processing of automotive components, such as engine blocks and transmission cases.

- Electronics Industry:

- Suitable for precision roughing and semi-finishing in the electronics industry, such as circuit boards and precision parts.

- Used for the preliminary processing of semiconductor devices and connectors.

Summary

The SDF-G-SUS Series Stainless Steel General Purpose 4-Flute Radius End Mill is a high-efficiency machining tool specifically designed for the roughing and semi-finishing of stainless steel materials. Its unique four-flute design, HRC 45° hardness, Balzers coating, and fine-grain tungsten carbide bar stock ensure excellent cutting efficiency, surface finish, heat resistance, and wear resistance. Widely applied in stainless steel machining, mold manufacturing, aerospace, automotive manufacturing, and the electronics industry, this end mill meets high-precision and high-reliability roughing and semi-finishing requirements. It not only improves production efficiency but also reduces maintenance costs, making it an ideal choice for modern manufacturing.

Bewertungen

Es sind noch keine Bewertungen vorhanden.