Eigenschaften

Anwendungen

Arbeitsmaterialien

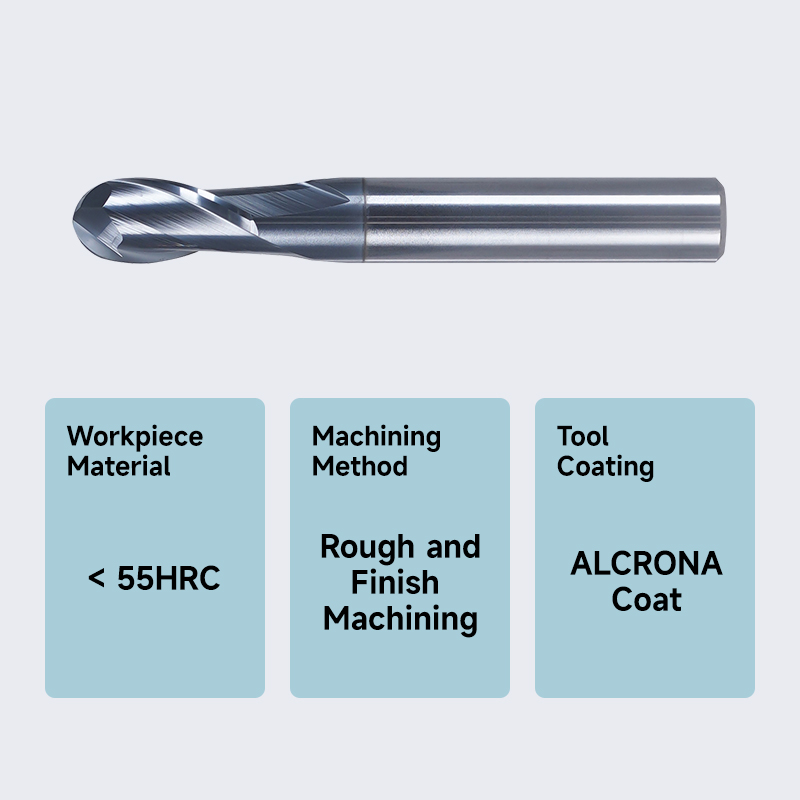

SDF-M Series Solid Carbide General Purpose High-Performance 2-Flute Ball Nose End Mill – ALCRONA Coating

1. Material and Coating

The SDF-M series ball nose end mill is made from high-quality solid carbide material, offering excellent strength and toughness to maintain stable performance in high-temperature and high-pressure environments. The surface is coated with a high-performance ALCRONA coating, providing exceptional wear and heat resistance, significantly improving cutting efficiency and tool life, especially for machining quenched steel up to HRC55. The ALCRONA coating enhances the tool’s anti-adhesion properties, effectively reduces cutting temperature, minimizes thermal deformation of both the tool and workpiece, and further improves machining accuracy and surface finish.

2. Design Features

Two-Flute Design:

- Efficient Chip Evacuation: The two-flute design ensures efficient chip evacuation and lower cutting forces, making it particularly suitable for high-speed machining. This design increases metal removal rates while reducing vibration and noise, ensuring a smooth cutting process.

- High Stability: The two-flute design provides better cutting stability and higher cutting speeds, suitable for fine machining and complex shape processing, especially when used on CNC machines for automated machining.

Ball Nose Design:

- Three-Dimensional Contouring: The ball nose design makes this end mill ideal for three-dimensional contouring and complex surface machining, achieving high precision and smooth surface finishes, particularly for applications requiring fine machining.

- Smooth Transition: The tool’s end features a round corner design, providing smooth transitions and reducing stress concentration, making it ideal for applications requiring high surface quality, such as precision mold manufacturing and aerospace components.

3. Precision and Stability

Strict manufacturing processes ensure micron-level precision for each cutting edge, providing high-precision and stable cutting results, especially for complex shapes and high-precision requirements. Advanced grinding and edge treatment technologies enhance the durability and resilience of the cutting edges, effectively extending the tool’s service life and ensuring efficient, stable performance over long-term use.

4. Suitable Materials

The SDF-M series ball nose end mill is primarily designed for machining quenched steel up to HRC55, common steels, stainless steel, and cast iron, delivering efficient, stable cutting performance and excellent surface quality.

5. Applications

Precision Mold Manufacturing:

- Complex Mold Cavities: Used for machining complex mold cavities and templates, ensuring rapid material removal and achieving high-precision surface quality, meeting the stringent requirements of mold manufacturing for accuracy and surface finish.

- High-Precision Requirements: Ideal for high-precision and high-surface-quality mold part machining, ensuring the final product’s high quality.

Aerospace:

- Aircraft Engine Components: Suitable for machining aircraft engine components and structural parts that require high precision and reliability, ensuring accurate and stable machining of complex geometries. For example, machining the three-dimensional contours and complex surfaces of turbine blades.

- High Reliability Requirements: The aerospace industry has extremely high demands for part reliability and precision, and the SDF-M series ball nose end mill can meet these strict requirements, ensuring machined parts have extremely high precision and surface finish.

Automotive Manufacturing:

- Automotive Components: Used for machining automotive components such as engine blocks and transmission housings with complex shapes, ensuring high precision and high-quality surface finishes. The ball nose end mill is particularly suitable for three-dimensional contour machining, such as the fine contours of cylinder heads and the complex shapes of intake and exhaust ports.

- Batch Production: Widely used in batch production in automotive manufacturing, ensuring efficient, stable, and high-quality cutting performance, enhancing production efficiency and product quality.

Bewertungen

Es sind noch keine Bewertungen vorhanden.