Características

Aplicaciones

Materiales de trabajo

SDF-P Series Tungsten Carbide Single-tooth trapezoidal thread milling cutter – TR 30°

Product Overview

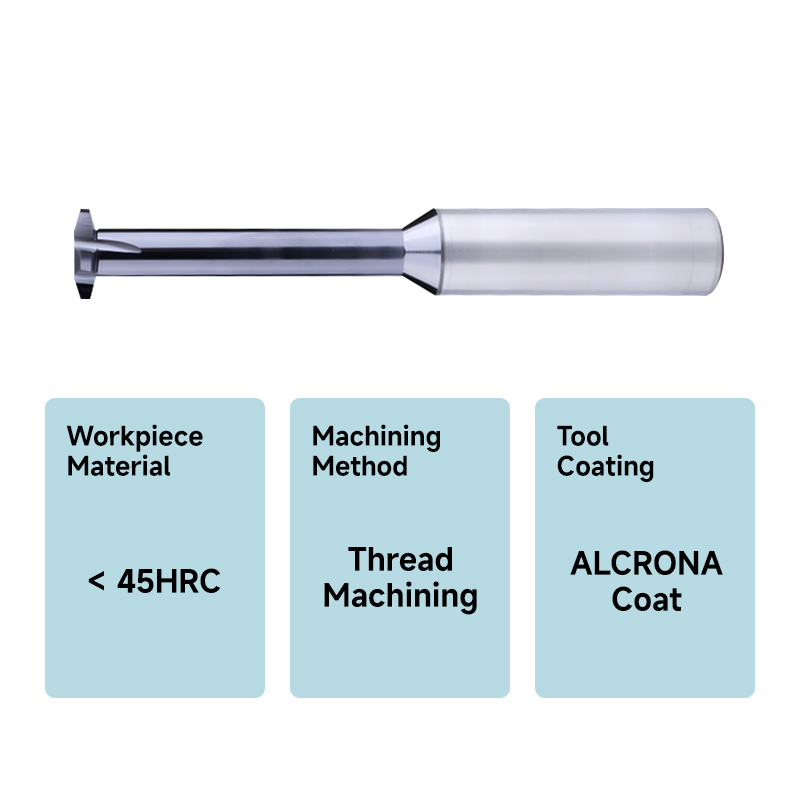

The SDF-P series tungsten carbide single-flute trapezoidal thread mill – TR30° is specifically designed for machining 30° trapezoidal threads. Trapezoidal threads are the primary form of screw transmission and are widely used in the main lead screw transmission of machine tools and the lead screw transmission of tool holders. This tool combines advanced material science, innovative design, and high-performance ALCRONA steel coating technology to address demanding machining applications and provide superior performance and reliability.

Product Features

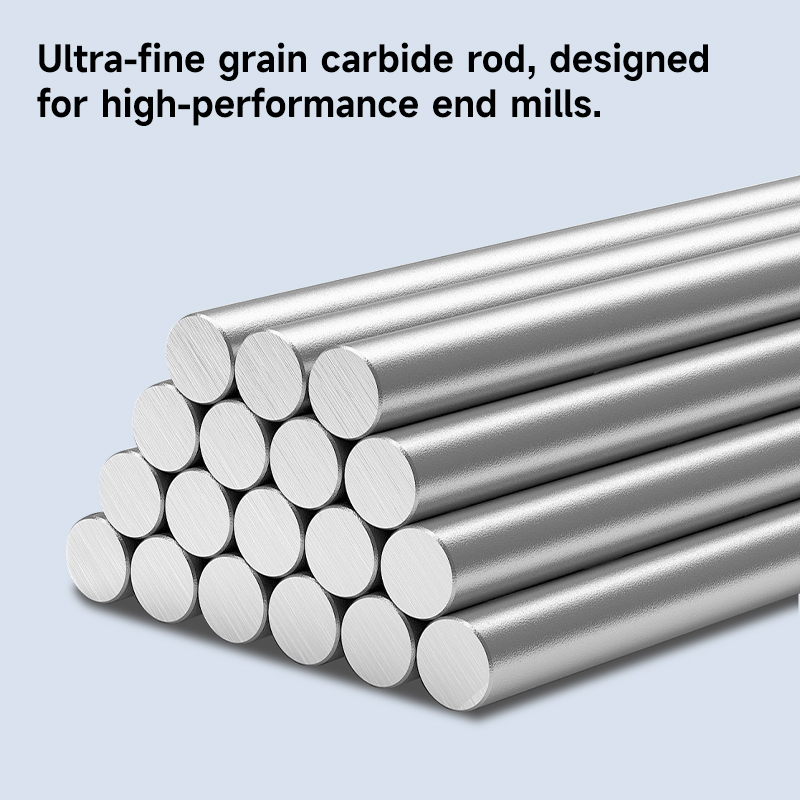

- High-Quality Tungsten Carbide Substrate:

- Uses high-purity, high-performance tungsten carbide substrate, ensuring stable performance under CNC high-speed cutting conditions.

- Offers excellent hardness and toughness, suitable for high-intensity machining environments, capable of withstanding high loads and speeds.

- Single-Flute Design:

- The single-flute design reduces cutting resistance, enhancing the tool’s versatility and ease of operation.

- Aids in efficient chip evacuation, preventing chip accumulation, and ensuring smooth and consistent cutting, particularly beneficial in deep hole and complex geometry machining.

- Specifically Designed for Machining 30° Trapezoidal Threads:

- Trapezoidal threads are the primary form of screw transmission and are widely used in the main lead screw transmission of machine tools and the lead screw transmission of tool holders.

- By adjusting feed rate and rotational speed, the mill can process multiple 30° trapezoidal thread specifications, suitable for various thread sizes and pitches.

- ALCRONA Steel Coating:

- Features ALCRONA steel coating, which provides excellent hardness and thermal stability, effectively reducing cutting temperature and extending tool life.

- Reduces cutting forces and improves surface quality, ensuring efficient and stable machining.

- Specifically designed for machining steel, maintaining superior performance under high-temperature and high-load conditions.

- Advanced German WALTER Five-Axis Grinding:

- Manufactured using advanced German WALTER five-axis grinding technology, ensuring geometric precision and surface quality.

- Guarantees consistent performance and strict tolerances, making each tool highly reliable and consistent.

Functions

- High Efficiency: The combination of the single-flute design and ALCRONA coating reduces cutting forces and increases cutting speed, thereby improving production efficiency. This is particularly advantageous when machining steel, where high efficiency and reduced cycle times are crucial.

- High Precision: The design and coating of the tool ensure high precision and excellent surface quality, meeting the stringent requirements of high-tech industries such as aerospace and automotive. Even in complex part machining, it maintains consistent precision and surface finish.

- Durability: The high-quality tungsten carbide substrate and advanced ALCRONA coating technology ensure the tool’s durability and reliability in harsh machining conditions. The long life and high reliability of the tool reduce replacement frequency and lower production costs.

- Ease of Operation: The single-flute design enhances the tool’s versatility and ease of operation, making it suitable for various machining environments.

Aplicaciones

- Aerospace Industry: Suitable for machining 30° trapezoidal threads in aircraft components, where high precision and reliability are critical.

- Automotive Industry: Ideal for machining 30° trapezoidal threads in automotive parts, such as engine components and transmission parts.

- Mechanical Engineering: Appropriate for machining 30° trapezoidal threads in various mechanical devices, molds, and tools.

- General Engineering: Suitable for a wide range of engineering applications requiring high-quality 30° trapezoidal threads, such as precision machinery and tool manufacturing.

-02.jpg)

-03.png)

Valoraciones

No hay valoraciones aún.