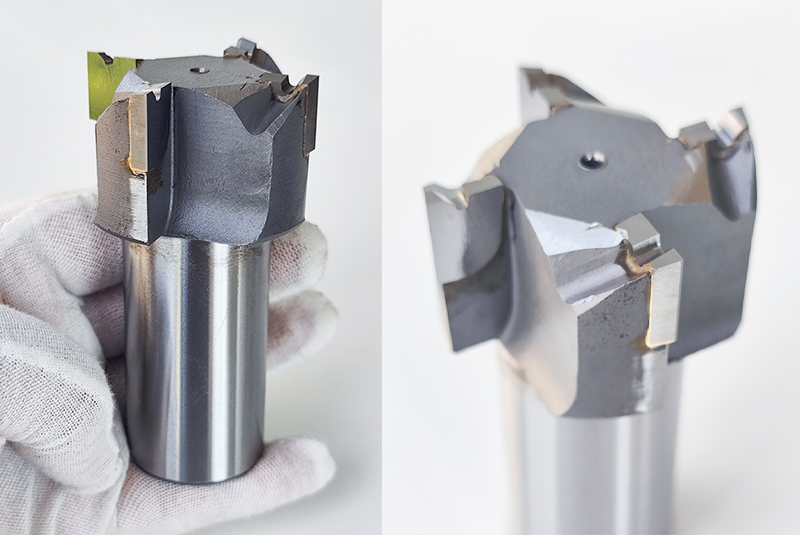

In modern CNC machining, when faced with complex materials, special structures, and stringent process requirements, standard tools often fall short of meeting customer needs. Recently, we developed a custom brazed tool for an automotive parts manufacturer, successfully addressing the challenges of machining deep cavities in cast iron components with complex shapes.

This brazed tool combines the high hardness of carbide with the excellent strength support of the tool body , becoming a key solution for improving production efficiency for the customer.

I. Project Background: Challenges in Deep Cavity Machining of Cast Iron

The customer is a company specializing in heavy-duty truck transmission housing manufacturing, requiring blind hole deep cavity milling on ductile iron QT500-7 . The specific requirements are as follows:

- Material : QT500-7 (tensile strength ≥ 500MPa, Brinell hardness HB210~260)

- Machining Type : Deep cavity blind hole contour milling

- Tool Requirements : Must withstand large cutting depths, high feed rates, and maintain stable operation over long periods

- Issues with Existing Tools :

- Standard indexable milling cutters frequently experienced chipping;

- Inserts were not securely fixed, leading to displacement during deep cavity cutting;

- Insufficient tool rigidity caused significant vibration and inconsistent surface quality.

Faced with these challenges, the customer decided to try a custom non-standard solution – brazed carbide tools .

II. Why Choose Brazed Tools?

Brazed tools are high-performance cutting tools where carbide tips are fixed to steel tool bodies using high-temperature brazing . Their core advantages include:

✅ Carbide tips provide excellent wear resistance : Made from ultra-fine grain carbide substrates, ensuring good thermal stability and wear resistance even under high-speed cutting conditions.

✅ Steel tool body ensures overall strength and vibration resistance : Supports large cutting depths and long overhangs, making it ideal for deep cavity and irregular contour machining.

✅ Integrated design enhances rigidity and precision : Eliminates the risk of loose inserts found in traditional indexable tools, improving machining stability.

This “rigid yet flexible” structural design allows brazed tools to excel in handling difficult-to-machine materials, complex geometries, and continuous heavy-duty cutting tasks.

III. Our Custom Solution: SDFTools Brazed Tool Technical Highlights

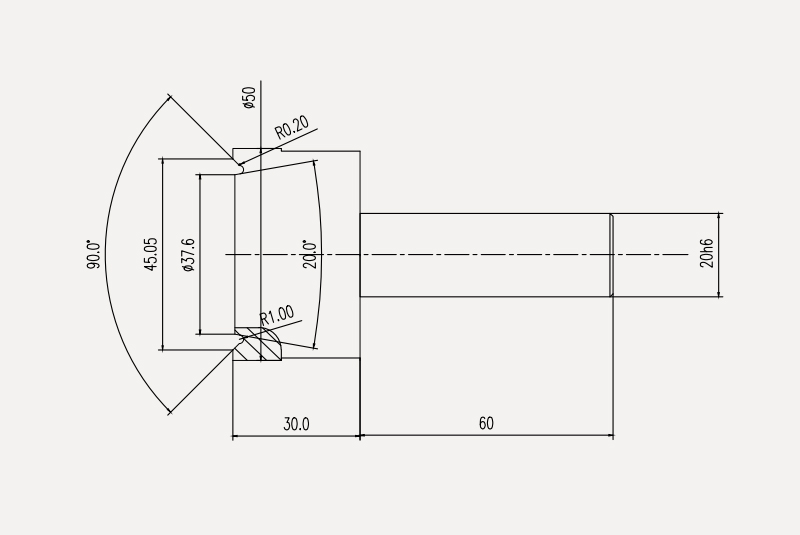

Based on the customer’s requirements, we designed a brazed end mill with an R-shaped contour profile , featuring the following key highlights:

🔧 1. Premium Carbide Material Selection

- The tip uses ultra-fine grain carbide (grain size ≤ 0.8μm) , offering excellent wear resistance and impact resistance, significantly extending tool life while minimizing built-up edge formation.

🔧 2. High-Strength Steel Tool Body Design

- The tool body is made from 42CrMo quenched and tempered steel , heat-treated to achieve HRC38-42, combining high strength with good toughness;

- Special anti-vibration structure design reduces resonance risks during deep cavity machining.

🔧 3. Optimized Brazing Process

- Uses silver-copper solder + vacuum furnace high-temperature brazing , ensuring a strong bond between the carbide and the tool body;

- The brazed interface undergoes metallographic testing, with bonding strength exceeding ISO standards to ensure long-term reliability.

🔧 4. Customized Contour Design

- The required contour is an R2.5mm radius + dual-edge profiling structure , used for finishing internal cavity transition surfaces;

- All dimensions are precisely controlled according to drawings, including diameter tolerance ±0.01mm and contour error ≤0.005mm.

🔧 5. Regrindable Design Extends Tool Life

- The tool has space for 3+ regrinds , significantly reducing overall usage costs;

- Supports edge honing, resharpening, and recoating services to ensure consistent performance after each regrind.

IV. Application Results: Performance Exceeds Expectations

After delivering the brazed tool for trial use, the customer achieved the following results:

| Métrica | Original Tool | SDFTools Custom Brazed Tool |

|---|---|---|

| Tool Life per Unit | ~120 pieces | ≥300 pieces |

| Machining Stability | Prone to chipping/breakage | Stable with no abnormal wear |

| Surface Quality | Ra1.6μm | Ra≤0.8μm |

| Regrinding Capability | Non-regrindable | Supports3+ regrinds |

Customer feedback: “This brazed tool not only significantly improved stability in our deep cavity machining but also reduced tool change frequency and setup time. Most importantly, it can be reground multiple times, truly achieving cost savings and efficiency improvements.”

V. Advantages of SDFTools Custom Brazed Tool Services

As a professional custom tool manufacturer, we offer full-process capabilities from design, brazing, coating, to precision inspection:

🔹 Wide Range of Specifications : Supports customization of various structures such as external turning tools, contour milling cutters, grooving tools, and form tools.

🔹 Multiple Carbide Options : Flexible matching of different grades of carbide based on material hardness, cutting speed, and machining methods.

🔹 High-Precision Manufacturing : Uses Swiss-imported five-axis grinders + laser inspection systems to achieve ±0.005mm contour accuracy.

🔹 Stringent Quality Control : Each tool undergoes IPQC/FQC double inspections before shipping, with complete inspection reports provided.

🔹 Fast Response Mechanism : Preliminary design completed within 72 hours, supporting global delivery and technical assistance.

VI. Wide Industry Applications, Supporting Efficient Smart Manufacturing

SDFTools brazed tools have been widely applied in the following fields:

- Automotive Industry : Contour milling of engine blocks and transmission housings

- Mold Industry : One-step forming of complex cavities and curved slots

- Aeroespacial : Efficient cutting of titanium alloys and superalloys for irregular components

- Energy Equipment : Batch processing of pump bodies, valve blocks, and other deep cavity components

Conclusion: Professional Customization Solves Industry Pain Points

With strong customization capabilities and a rigorous quality control system, SDFTools continues to deliver brazed tool solutions that combine high hardness and high strength . Whether you’re dealing with cast iron, stainless steel, or difficult-to-machine alloys, we can provide stable, reliable, and efficient custom tooling solutions.

If you’re looking for a brazed tool that balances wear resistance and strength , contact us today to create the perfect tool tailored to your needs!