Características

Aplicaciones

Materiales de trabajo

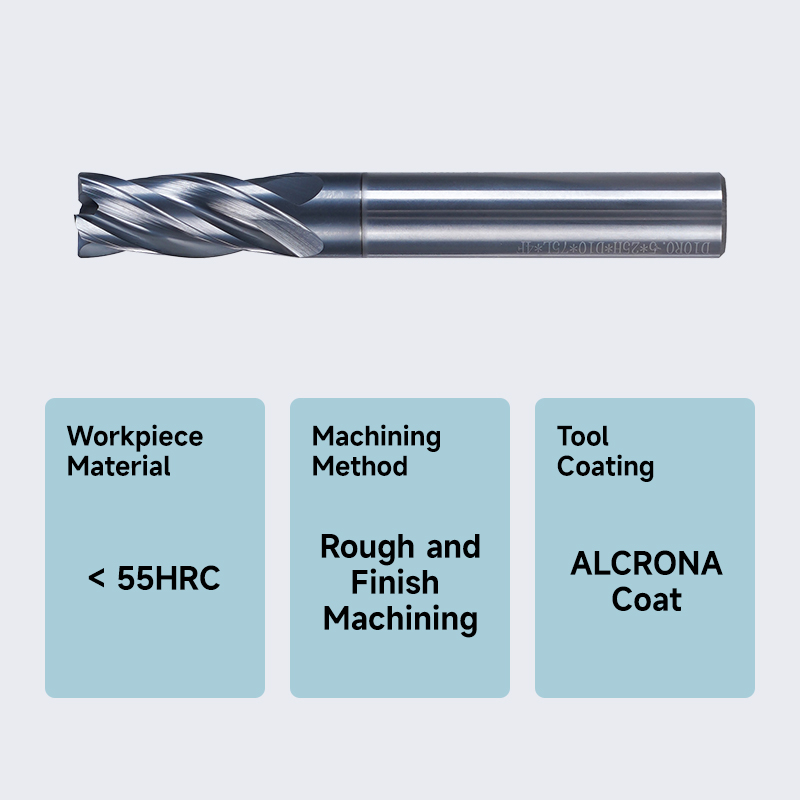

M Series General Purpose High-Performance 4-Flute Cor Radius End Mill is a highly efficient tool specifically designed for machining high-hardness materials. Its unique design and advanced manufacturing processes ensure superior performance under various demanding conditions.

- 4-Flute Design: The four cutting edges not only improve cutting efficiency but also reduce cutting forces, making the machining process smoother and more efficient. This design helps to increase productivity and reduce tool wear.

- Cor Radius Design: The end of the tool features a radius (cor) design, which provides smooth transitions and reduces stress concentration. This design is particularly suitable for applications requiring high surface finish quality, such as mold making and precision part machining.

Revestimiento

- Advanced Coating Technology: This end mill is equipped with advanced wear-resistant coating technology. The coating significantly enhances the tool’s durability and cutting efficiency, extending its service life. The coating also reduces friction and heat buildup, further improving the tool’s performance.

Function

- High-Hardness Material Specialization: Specifically optimized for high-hardness materials, this end mill maintains stable cutting performance and reduces wear during machining. It is suitable for various hard materials up to 55°.

- Efficient Cutting: The four-flute design increases cutting efficiency and reduces cutting forces, ensuring a smoother and more efficient machining process.

- Smooth Transition: The radius design at the end of the tool provides smooth transitions and reduces stress concentration, making it ideal for applications requiring high surface finish quality.

Application Scenarios

- Wide Applicability: Suitable for a wide range of materials, including steel, stainless steel, cast iron, and more, providing broad applicability across different industries.

- Industry Applications: Widely used in aerospace, automotive manufacturing, mold making, and general machining industries, especially in applications requiring high precision and high-quality surface finishes.

- Types of Machining: Suitable for slot milling, side milling, contour milling, and various other types of machining operations, meeting diverse machining needs.

Summary

The M Series General Purpose High-Performance 4-Flute Cor Radius End Mill is a highly efficient tool specifically designed for machining high-hardness materials. Its unique 4-flute design and cor radius design provide excellent cutting efficiency and smooth transitions. Advanced coating technology significantly enhances the tool’s durability and cutting efficiency, extending its service life. With wide applicability across various materials and machining applications, this end mill excels in industries requiring high precision and high-quality surface finishes, such as aerospace, automotive, and mold making. Whether for slot milling, side milling, or contour milling, this tool offers reliable and stable performance, making it an indispensable tool in modern manufacturing.

Valoraciones

No hay valoraciones aún.