Características

Aplicaciones

Materiales de trabajo

SDF-G Series General Purpose Enhanced Internal Cooling 3D (Three-Diameter) Solid Carbide Drill

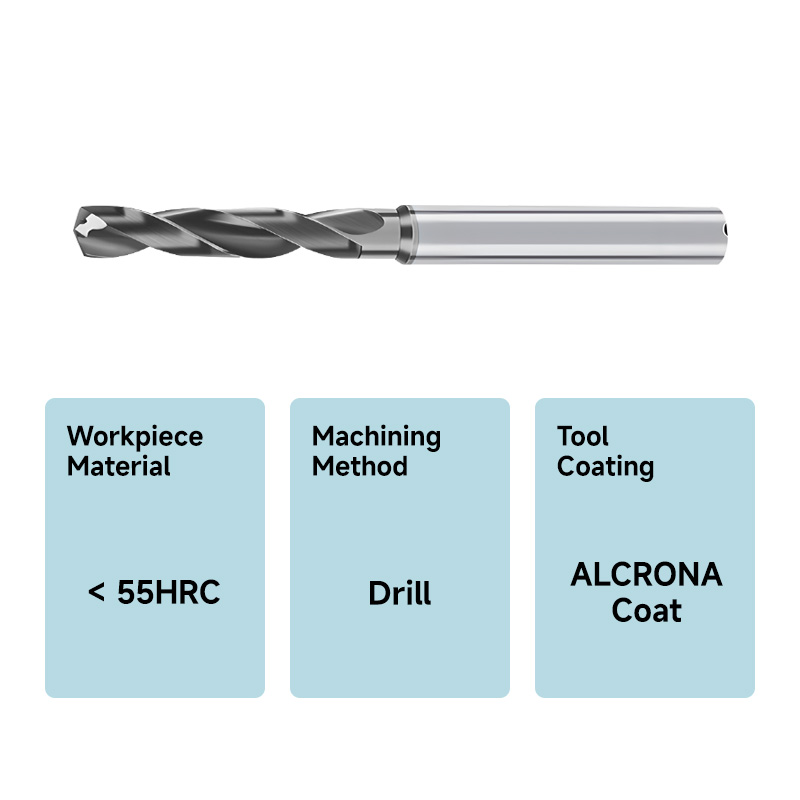

- Product Overview: The SDF-G series general purpose enhanced internal cooling 3D solid carbide drill is a high-performance tool designed for efficient machining. Manufactured from high-quality micro-grain tungsten carbide, this drill ensures superior performance on hard materials such as hardened steel (HRC55°). It is suitable for various precision mold and component machining tasks, achieving efficient and high-quality drilling operations across different materials.

- Internal Cooling System: Equipped with an advanced internal cooling system, the drill delivers coolant directly to the cutting zone via internal channels. This design provides superior cooling efficiency, extending tool life and significantly enhancing machining accuracy and surface quality. The efficient cooling system effectively reduces cutting temperatures, minimizes thermal deformation, and ensures a stable machining process.

- Optimized Flute Design: The drill’s flute geometry is meticulously designed to optimize chip evacuation, ensuring smooth chip removal. This design reduces issues like chip clogging and overheating, thereby improving work efficiency and processing reliability. The optimized flute also helps increase drilling speed and quality.

- ALCRONA High-Wear Resistant Coating: The surface is coated with ALCRONA high-wear resistant coating, which significantly enhances the drill’s resistance to high temperatures and wear. This coating maintains stable cutting temperatures under high-speed machining conditions, reduces friction, and decreases wear rates, thereby dramatically increasing the tool’s service life and machining efficiency. The application of ALCRONA coating ensures excellent performance even after prolonged use.

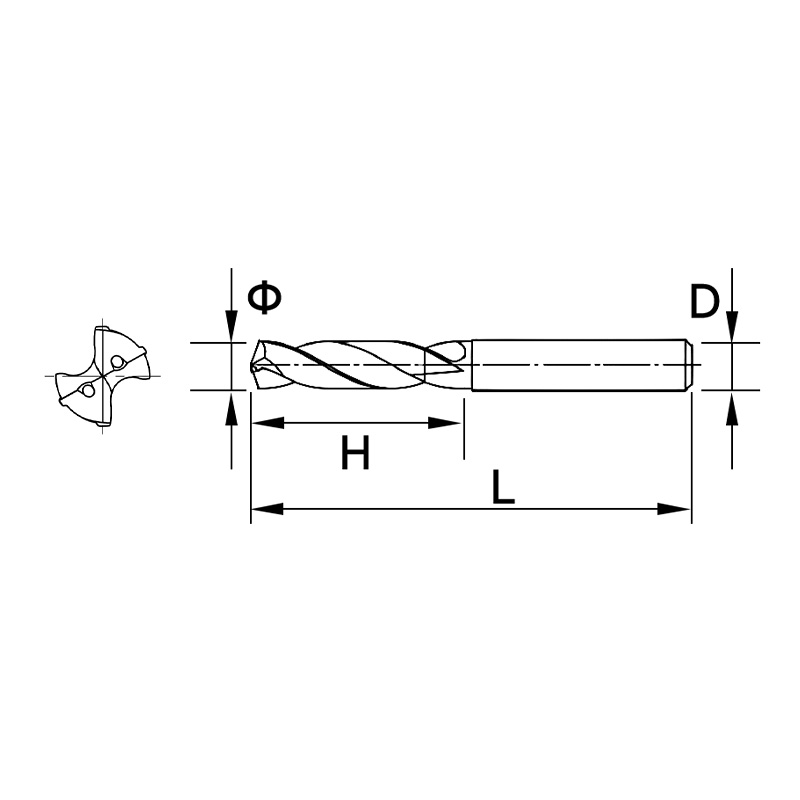

- Three-Diameter Length Design: With a length three times its diameter, the drill offers excellent guidance and stability, contributing to precise drilling results. This design effectively reduces deflection and vibration, ensuring straightness and roundness in the drilled holes. The three-diameter design also excels in deep-hole drilling, making it suitable for applications requiring high precision and stability.

Application Scenarios

- Fabricación de automóviles: Ideal for rapid drilling of cast iron, steel, and other hard materials (HRC ≤ 55°). It achieves efficient and high-quality drilling operations, especially in applications requiring high precision and stability.

- Mold Making: When precision drilling of mold components is required, the SDF-G series drill performs exceptionally well, particularly for high-strength materials.

- Aerospace and Heavy Machinery Manufacturing: Suitable for complex structural components and high-strength materials in aerospace and heavy machinery industries. Its superior wear resistance and stability make it an ideal choice for processing difficult-to-machine materials.

Summary

The SDF-G series general purpose enhanced internal cooling 3D solid carbide drill leverages its high-quality material, advanced internal cooling system, unique flute design, and high-performance ALCRONA coating to become an ideal choice for precision mold and component machining. It not only excels in long-duration cutting of hard materials (HRC55°) but also provides outstanding performance and reliability across various machining environments. Whether for batch production or complex part machining, the SDF-G series offers stable and efficient solutions, ensuring machining quality and efficiency.

Valoraciones

No hay valoraciones aún.