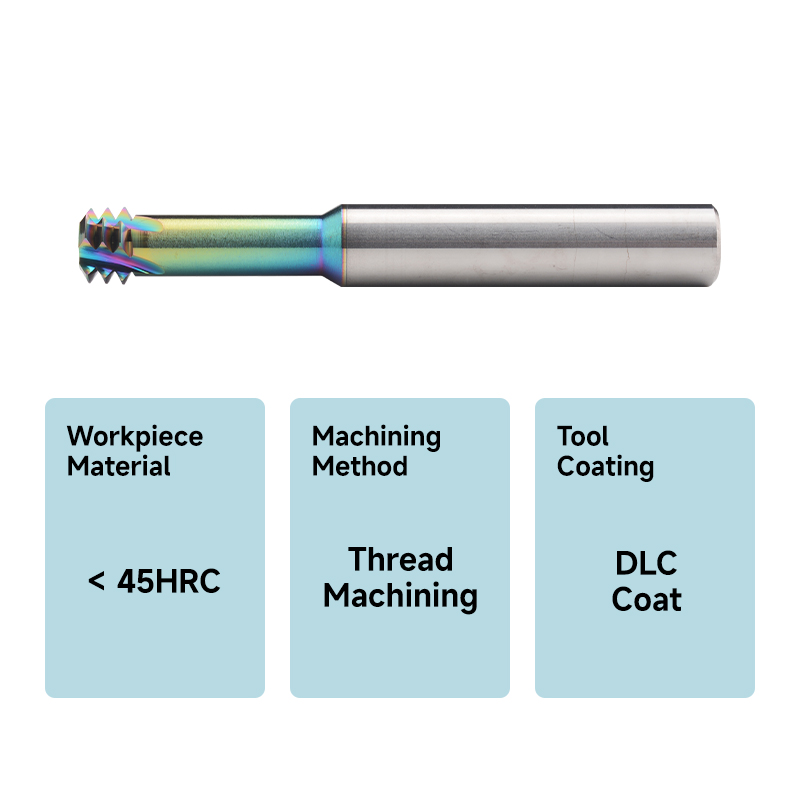

Характеристики

Приложения

Материалы для работы

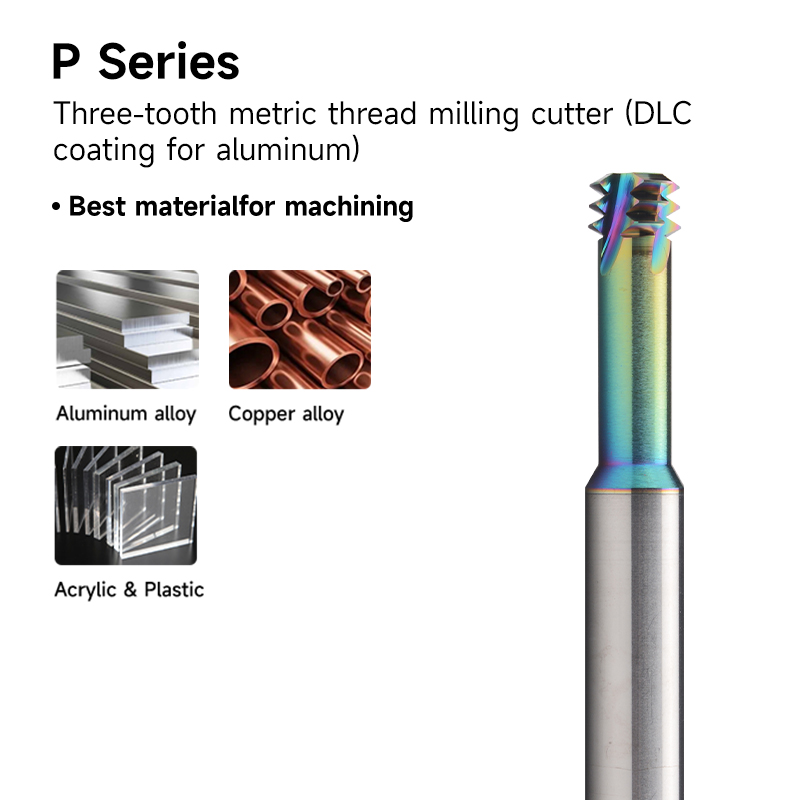

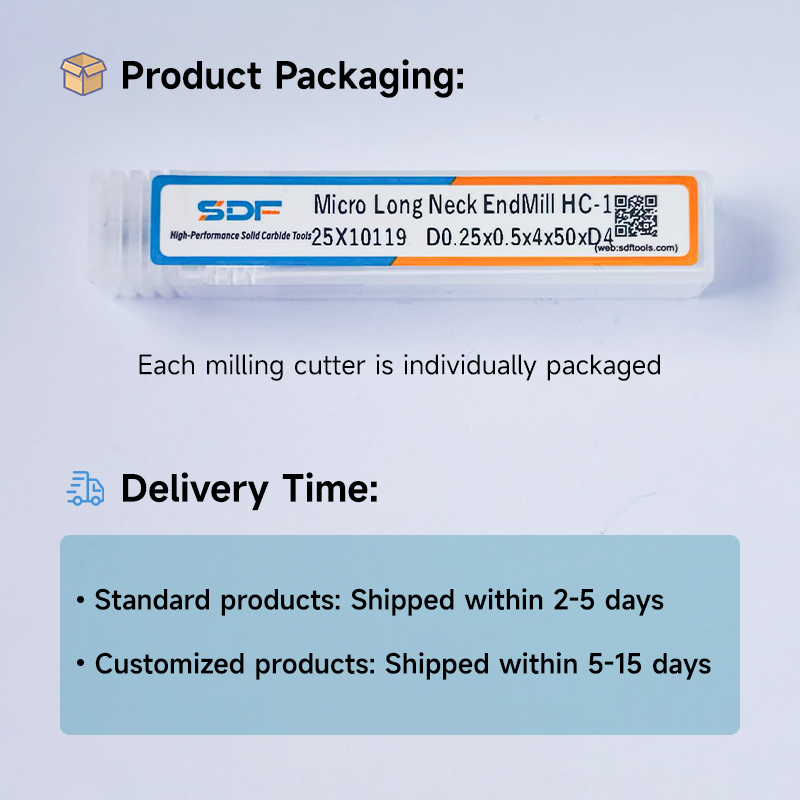

SDF-P Series Tungsten Carbide Triple Tooth Metric Thread Milling Cutter for Copper and Aluminum

- Особенности конструкции:

- Triple Tooth Design: The milling cutter features a triple tooth design, enabling multi-point cutting. This design significantly enhances cutting efficiency, making it particularly suitable for machining small-diameter threads. The triple tooth configuration allows for more efficient material removal and smoother cutting action.

- Tungsten Carbide Base Material: The tool is made from high-quality tungsten carbide, which ensures exceptional hardness and wear resistance. This material can withstand high-intensity and high-speed cutting conditions, maintaining its performance and extending the tool’s service life.

- Coating Characteristics:

- DLC Coating: The surface of the milling cutter is coated with a DLC coating, which has the lowest friction coefficient, effectively reducing friction and heat generation during the cutting process.

- High Anti-Welding and Anti-Corrosion Properties: The DLC coating provides high anti-welding and anti-corrosion properties, making it ideal for machining non-ferrous metals such as copper alloys and aluminum alloys. The coating also enhances the tool’s resistance to wear and adhesion, further extending its service life and improving the surface finish of the machined materials.

- Function and Performance:

- High Efficiency: The triple tooth design and low-friction DLC coating work together to ensure high cutting efficiency. The multi-point cutting capability reduces the time required for machining, making it an excellent choice for high-volume production.

- Long Service Life: The combination of high-quality tungsten carbide and the durable DLC coating significantly extends the tool’s service life. This reduces the frequency of tool replacements and lowers overall production costs.

- High Precision: The precision manufacturing process ensures that the milling cutter maintains high geometric accuracy and consistency, meeting the high standards required for precision machining. Whether for roughing or finishing, the tool delivers consistent and reliable results.

- Smooth Cutting Action: The optimized geometry and low-friction coating ensure smooth and consistent cutting, reducing vibration and deformation during the machining process. This results in higher machining accuracy and better surface quality.

- Поля приложений:

- Copper Alloys and Aluminum Alloys: The milling cutter is specifically designed for machining copper alloys and aluminum alloys, which are commonly used in various industries due to their lightweight and corrosion-resistant properties.

- Other Non-Ferrous Metals: It is also suitable for machining other non-ferrous metals, such as brass, bronze, and other alloys, where high precision and surface quality are essential.

- Acrylic Materials: The tool can be used for machining acrylic materials, providing clean and precise cuts, which are crucial for applications requiring high-quality surface finishes.

- Precision Mechanical Parts and Molds: The milling cutter is ideal for machining precision mechanical parts and mold components, as well as other high-precision applications. It is particularly useful in industries such as automotive, electronics, and general manufacturing, where high accuracy and surface quality are critical.

Отзывы

Отзывов пока нет.