Характеристики

Приложения

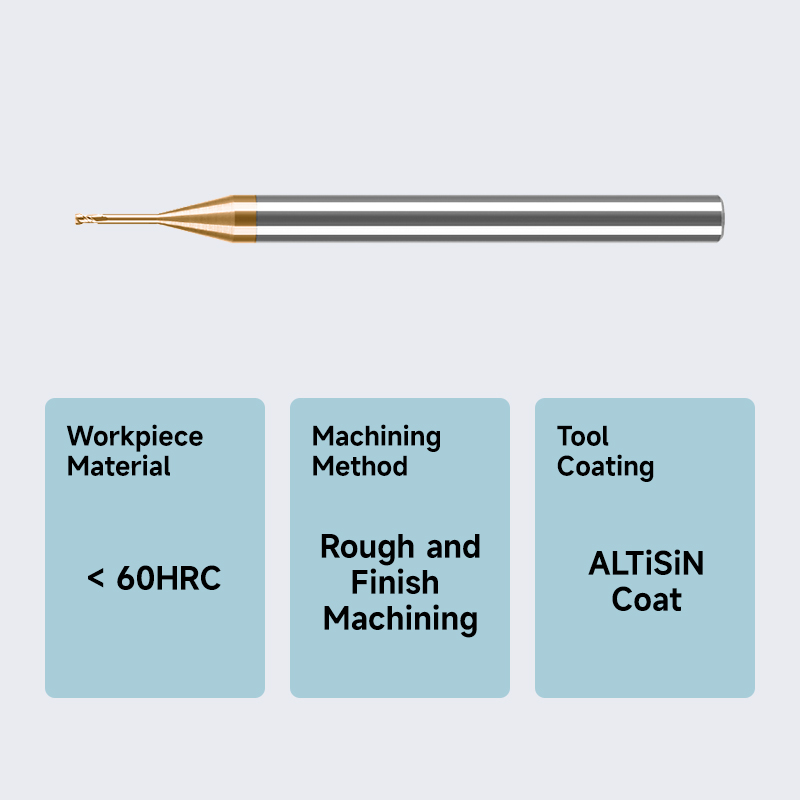

Материалы для работы

Твердосплавная 2-фрезерная концевая фреза общего назначения с глубокой канавкой серии SDF-D - покрытие ALTiSiN

Product Overview

The SDF-D series solid carbide general purpose 2-flute deep groove end mill is designed for high precision and efficient machining. This high-performance tool, manufactured from high-quality fine-grain micro-particle tungsten carbide, ensures exceptional performance on hardened steels (up to HRC60°) and is suitable for a variety of precision mold and component machining tasks.

Materials and Manufacturing Process

- High-Quality Fine-Grain Micro-Particle Tungsten Carbide Material:

- The tool is made from high-quality fine-grain micro-particle tungsten carbide bar stock, providing extremely high hardness and toughness. It maintains stable cutting performance under high temperature and pressure conditions, offering durable and reliable machining experiences.

- Advanced Grinding Technology:

- Precision ground using advanced German WALTER 5-axis grinders, this process achieves ultra-high precision for both the cutting diameter and shank diameter, ensuring optimal geometric accuracy and surface quality that meet high-precision machining requirements.

Особенности конструкции

- Unique Cutting Edge and Geometric Design:

- Featuring a unique 2-flute design with optimized cutting edge geometry, it ensures high metal removal rates and smooth chip evacuation, reducing cutting forces and vibrations. This improves processing efficiency and surface quality.

- Large Chip Clearance Design:

- The large chip clearance design effectively prevents chip clogging, ensuring continuous and stable cutting processes, especially suitable for long-duration deep groove milling operations.

Технология нанесения покрытий

- ALTiSiN High-Wear-Resistant Coating:

- The surface is coated with ALTiSiN, a high-wear-resistant coating that significantly enhances the tool’s wear resistance and anti-adhesion properties. This extends the tool life and improves the surface finish of machined parts. The coating is particularly effective for long-duration machining of hardened materials, exhibiting excellent durability.

Application Range

- Wide Applicability:

- This series of end mills has high versatility, suitable for machining various materials including but not limited to hardened steels (HRC60°), ordinary steels, stainless steel, cast iron, and various high-hardness alloys.

- Precision Mold and Component Machining:

- Specifically designed for precision mold and component machining, it can achieve complex geometries and high precision requirements, ensuring the high quality and longevity of molds and components.

- Deep Groove Milling:

- Designed specifically for deep groove milling, it ensures consistent depth and width while maintaining high precision and stability. It is ideal for industries requiring high-precision deep groove machining, such as aerospace, automotive manufacturing, and medical devices.

- Other Machining Methods:

- Besides deep groove milling, it is also suitable for face milling, side milling, and slot milling, ensuring efficient and precise performance across different machining tasks.

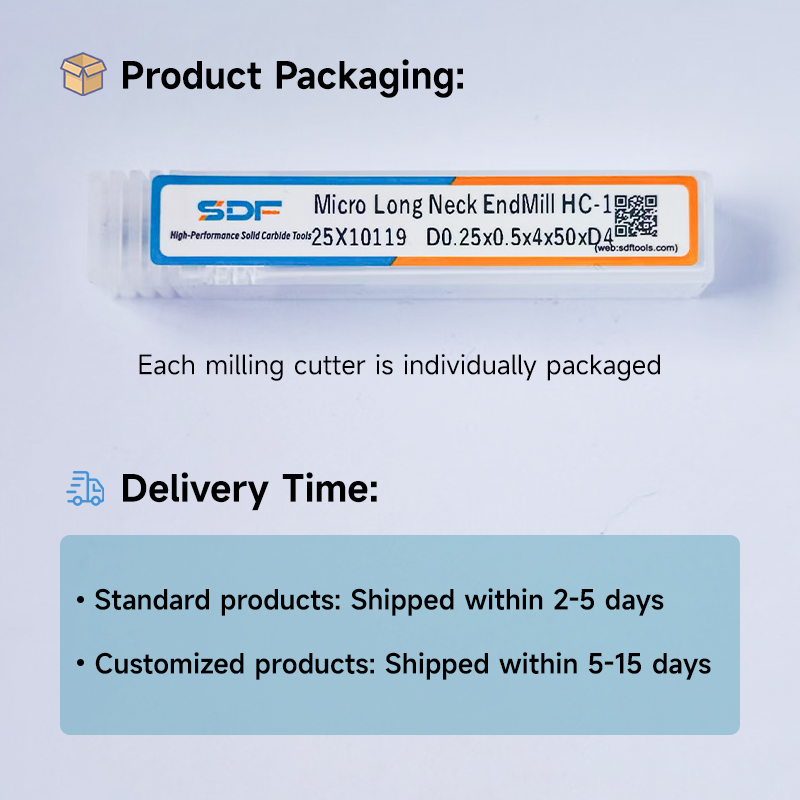

Quality Assurance

- Strict Quality Inspection:

- Each tool undergoes strict quality inspection using German ZOLLER equipment, ensuring high and stable performance that meets high-precision machining requirements.

Summary

The SDF-D series solid carbide general purpose 2-flute deep groove end mill combines high-quality materials, advanced grinding technology, unique design features, and high-performance ALTiSiN coating, making it an ideal choice for precision mold and component machining. Suitable for long-duration machining of hardened materials (HRC60°), it offers outstanding performance and reliability in various machining environments. Whether for batch production or complex workpiece machining, the SDF-D series provides a stable and efficient solution, ensuring machining quality and efficiency.

Отзывы

Отзывов пока нет.