Характеристики

Приложения

Материалы для работы

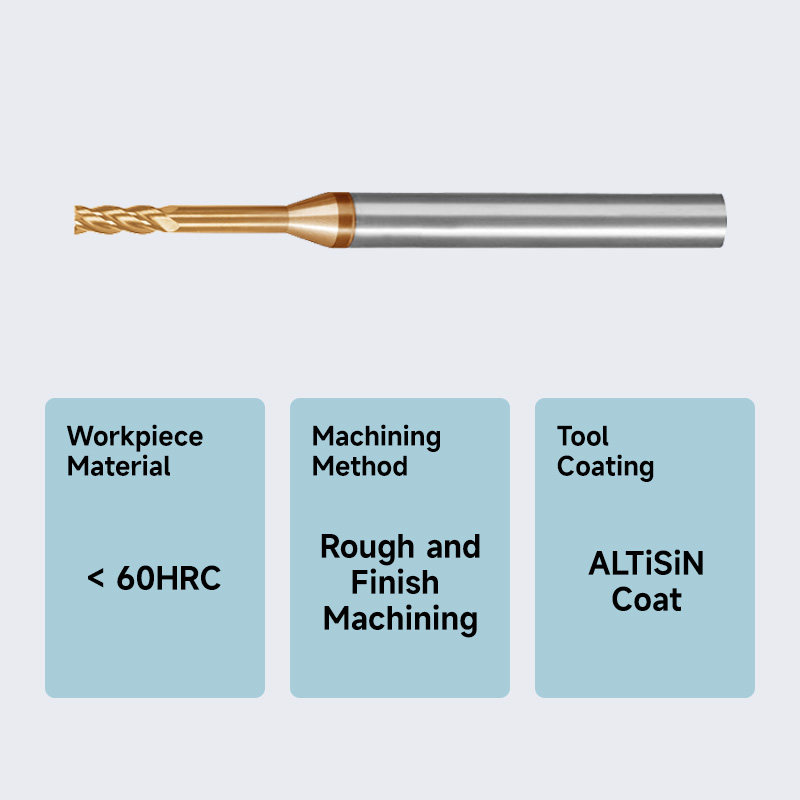

Серия SDF-D Твердосплавная 4-х фреза с глубокой канавкой радиусная концевая фреза - покрытие ALTiSiN HRC60°

Product Overview

The SDF-D series solid carbide 4-flute deep groove radius end mill is a high-performance tool specifically designed for prolonged cutting on hard materials such as HRC60° hardened steel. It combines high-quality micrograin tungsten carbide material, advanced grinding technology, unique geometric design, and high-performance ALTiSiN coating, making it widely applicable for precision mold and component machining tasks. This milling tool not only possesses outstanding technical characteristics but also demonstrates exceptional application value in complex component processing across multiple industries.

Technical Features and Advantages

- High-Quality Micrograin Tungsten Carbide Material:

- Made from high-quality micrograin tungsten carbide stock, ensuring the tool has extremely high hardness and toughness, providing durable and stable performance, especially suitable for prolonged cutting of hard materials.

- Advanced Grinding Technology Achieves Ultra-High Precision:

- Utilizes advanced grinding technology to achieve ultra-high accuracy in both cutting diameter and shank diameter, ensuring geometric precision and surface quality, particularly suitable for high-precision deep groove milling in molds and components. This high precision is crucial for consistent and stable deep slot and complex surface processing.

- Unique 4-Flute Design with Optimized Rounded Edge Geometry:

- Features a unique 4-flute design combined with optimized rounded edge geometry, ensuring high metal removal rates and smooth chip evacuation, reducing cutting forces and vibration. The large chip flute design effectively prevents chip clogging, ensuring continuous and stable cutting processes, especially for deep grooves and complex curved surfaces. The design excels in deep slot machining, maintaining consistent depth and width while minimizing tool wear.

- High-Performance ALTiSiN Wear-Resistant Coating:

- Coated with ALTiSiN for superior wear resistance and anti-adhesion properties, significantly extending tool life and improving the surface finish of machined parts. This coating is particularly effective for long-duration cutting of HRC60° hardened steels, demonstrating high fracture resistance and ensuring long-term stable performance. The coating technology further enhances its performance in complex deep slot machining.

- Wide Range of Material Suitability:

- Suitable for materials with hardness up to HRC60°, including hardened steels, mild steel, stainless steel, cast iron, and various high-hardness alloys, showcasing exceptional versatility. It is especially ideal for applications requiring efficient deep groove and complex surface machining.

Milling Methods

- Deep Groove Milling: Specifically designed for deep grooves and narrow slots, ensuring consistent depth and width while maintaining high precision and stability, suitable for aerospace and automotive manufacturing.

- Complex Surface Milling: Used for machining complex three-dimensional surfaces, such as cavities and cores in molds, ensuring high precision and smooth surface quality.

- Side and Face Milling: Efficiently performs side milling and face milling, suitable for machining flat surfaces and stepped structures, ensuring smooth edges and precise finishes.

- Plunge Milling: Conducts plunge milling operations through vertical feed movements, suitable for machining deep holes and internal slots, ensuring good chip evacuation and machining stability.

- Helical Interpolation Milling: Utilizes helical interpolation paths for arc and curve machining, suitable for high-precision applications in medical devices and electronic components.

Приложения

- Aerospace Industry: Used in connecting areas of large structural components like turbine blades, fuselages, and wings of aircraft, achieving lightweight design and structural stability through deep groove milling.

- Автомобильное производство: Suitable for high-precision machining of critical components such as internal cooling water passages and lubrication channels in engine blocks, transmission housings, and suspension system parts, ensuring thermal management, lubrication efficiency, and smooth power transmission.

- Производство пресс-форм: Processes flow channels and embedded parts in plastic injection molds, ensuring precise fit and high-quality finished products; provides high wear resistance and dimensional accuracy for metal die-casting molds.

- General Machinery Manufacturing: Ensures proper function and stable operation by machining fluid guiding channels in hydraulic and pneumatic systems (such as pump bodies and valve bodies) and precise deep grooves for bearing installation positions in machinery.

- Other Industries: Suitable for manufacturing elements like heat sinks and enclosures in electronic devices, and special occasions requiring deep groove milling, such as root sections of wind turbine blades and seals in nuclear power plants.

Отзывы

Отзывов пока нет.