Характеристики

Приложения

Материалы для работы

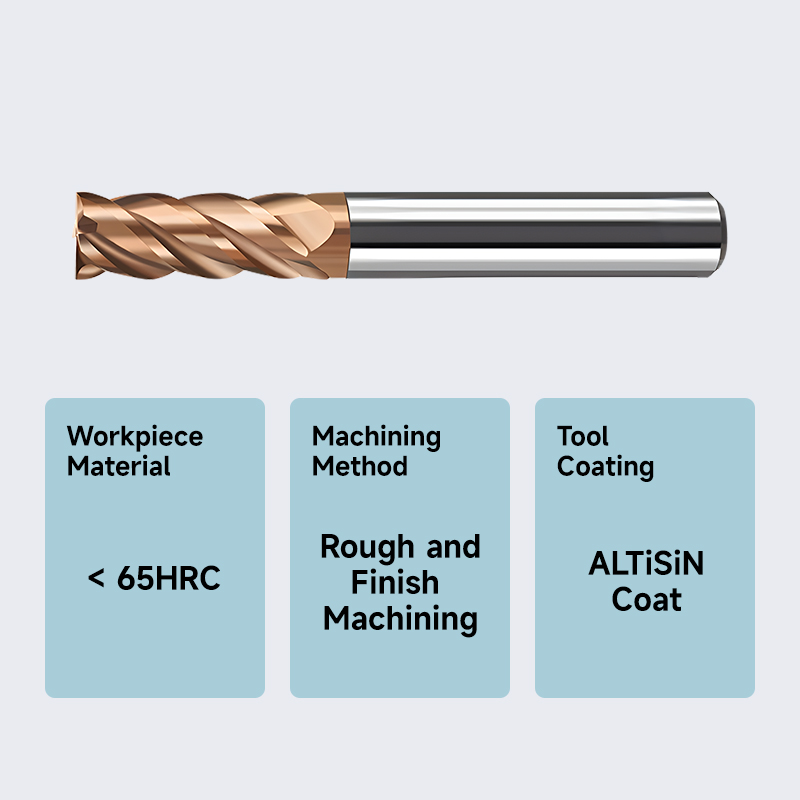

SDF-H Series Solid Tungsten Carbide High-Speed, High-Hardness 4-Flute End Mill with ALTiSiN Coating

1. Product Design

- Материал и твердость: The milling cutter is made from solid tungsten carbide, ensuring extremely high hardness and excellent wear resistance. This material maintains stable performance under high-intensity and high-speed cutting conditions, suitable for demanding machining environments. It is particularly designed for machining heat-treated high-hardness materials such as alloy steel and mold steel (HRC60), providing superior cutting performance. The high-density structure of tungsten carbide also enhances impact resistance and toughness, extending the tool’s lifespan.

- Optimized Four-Flute Structure and Special Geometric Design: The milling cutter features an optimized four-flute structure and special geometric design. Each flute handles a portion of the cutting work, gradually completing the machining process to ensure efficient material removal and superior surface quality. The four-flute design increases cutting speed and feed rate while reducing vibration and deformation, enhancing machining accuracy and stability. By optimizing the cutting edge angles and rake angles, it further reduces cutting forces, minimizes tool wear, and extends tool life. Additionally, a negative chamfer design helps improve edge strength and reduce chipping risks.

- Edge Blunting Technology: Advanced edge blunting technology is applied to enhance edge toughness and durability. Blunting treatment effectively prevents micro-cracks from forming, reduces initial wear during the early stages of use, and thus prolongs the overall tool life. This treatment also improves stability and surface finish during the cutting process, especially when machining high-hardness materials.

2. Coating Technology

- ALTiSiN Coating: The surface is coated with ALTiSiN, providing high hardness, low friction, and excellent thermal stability, significantly improving cutting force and tool life. The ALTiSiN coating has outstanding high-temperature and oxidation resistance, effectively lowering cutting temperatures, minimizing thermal deformation, and enhancing machining quality and tool life. Additionally, the coating offers excellent lubrication properties, further reducing cutting resistance, preventing chip adhesion, and improving chip evacuation. This coating excels in high-hardness material machining, especially under high-temperature and high-pressure conditions.

3. Product Functionality

- Cooling Method Compatibility: Compatible with various cooling methods, including mist cooling, water cooling, and air cooling, ensuring stable performance in different machining environments and adapting to various industrial application requirements. Different cooling methods can be selected based on specific material and process requirements to optimize cooling efficiency, extend tool life, and enhance machining efficiency and surface quality. For example, mist cooling is suitable for high-speed dry cutting, while water cooling and air cooling are ideal for applications requiring rapid cooling or clean chip removal.

- Efficient Material Removal and Precision: The optimized four-flute structure and special geometric design enable the milling cutter to remove large amounts of material quickly while maintaining excellent surface finish. The combination of advanced geometry and high-quality coating ensures high precision and stability under heavy loads and high speeds. Whether for roughing or finishing, this milling cutter provides reliable performance.

4. Suitable Milling Methods

- Climb Milling: Recommended for most machining scenarios, especially for high-hardness materials. Climb milling reduces tool wear, lowers cutting forces, and improves surface finish.

- Conventional Milling: Suitable for specific applications like thin-walled part machining, where it can minimize part deformation and vibration.

- Side Milling: Ideal for machining complex side contours and slot structures. The optimized geometric design and four-flute structure ensure efficient material removal and precise dimensional control.

5. Application Scenarios

- Механическое производство: Widely used in machining critical components such as engine blocks and gearbox housings, ensuring efficient material removal and high-precision surface quality. Its high hardness and wear resistance make it an ideal choice for mechanical manufacturing.

- Производство пресс-форм: Suitable for roughing and finishing complex shapes like mold cavities and templates, ensuring rapid material removal and achieving high-precision surface quality, meeting the stringent requirements of mold manufacturing for accuracy and surface finish.

- Аэрокосмическая промышленность: Used for high-precision and complex shape parts machining, such as engine blades and structural components, meeting strict precision and reliability standards. Its superior cutting performance and durability ensure reliable and long-term use in demanding environments.

6. Manufacturing Process

- Manufactured Using German Walter 5-Axis CNC Grinding Technology: Manufactured using German Walter’s 5-axis CNC grinding technology, ensuring exceptional manufacturing precision and consistency. The 5-axis CNC technology ensures each cutting edge reaches micron-level precision, ensuring optimal performance during actual machining. This high-precision manufacturing process further enhances tool performance and service life, ensuring stable operation over extended periods.

Отзывы

Отзывов пока нет.