Характеристики

Приложения

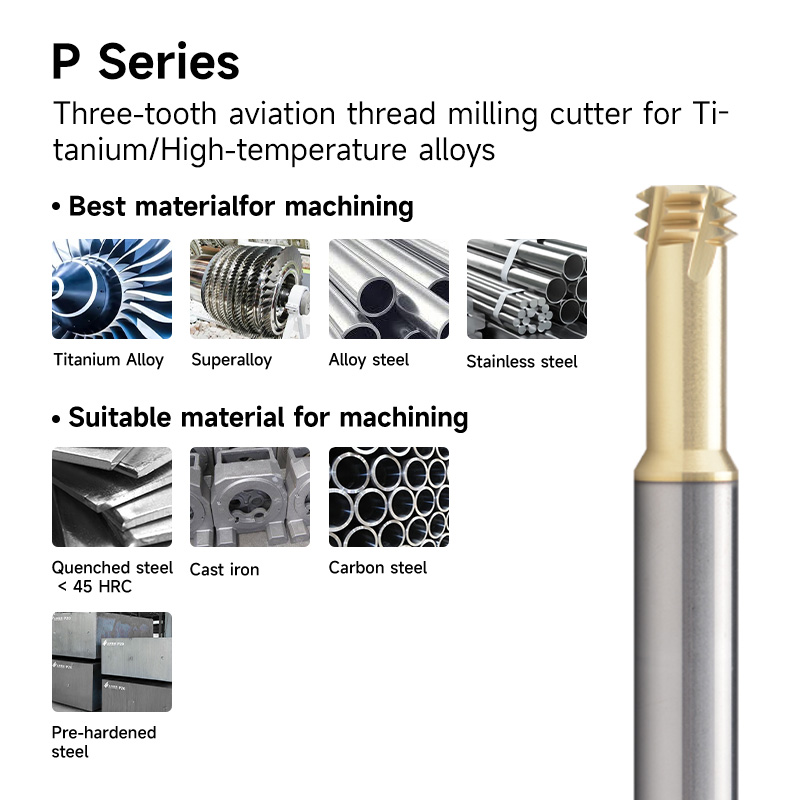

Материалы для работы

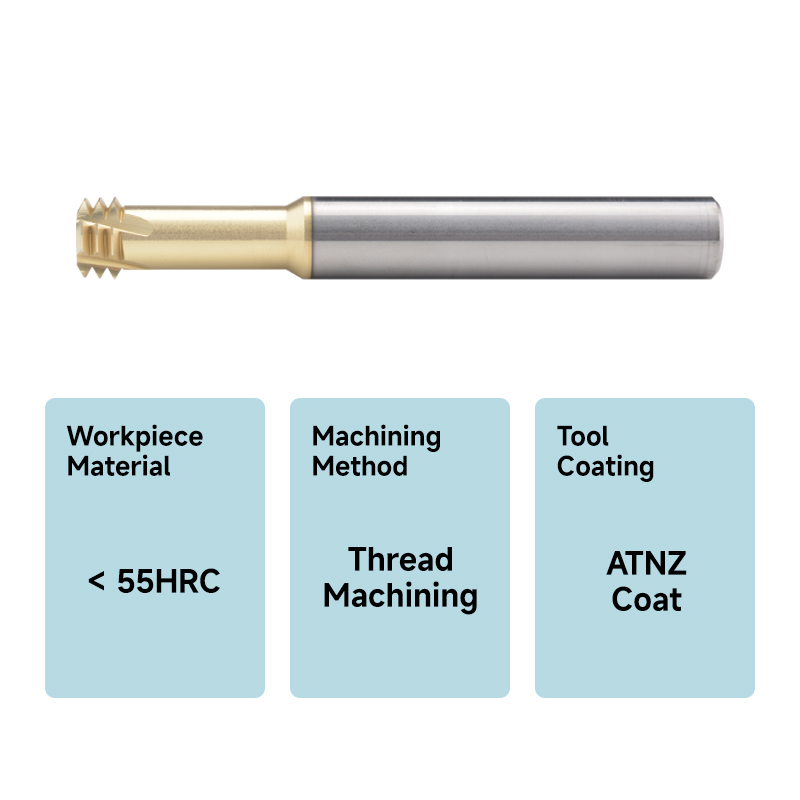

SDF-P Series Tungsten Carbide Triple Tooth Aerospace-Specific Thread Milling Cutter for High-Temperature Alloys and Titanium Alloys

- Особенности конструкции:

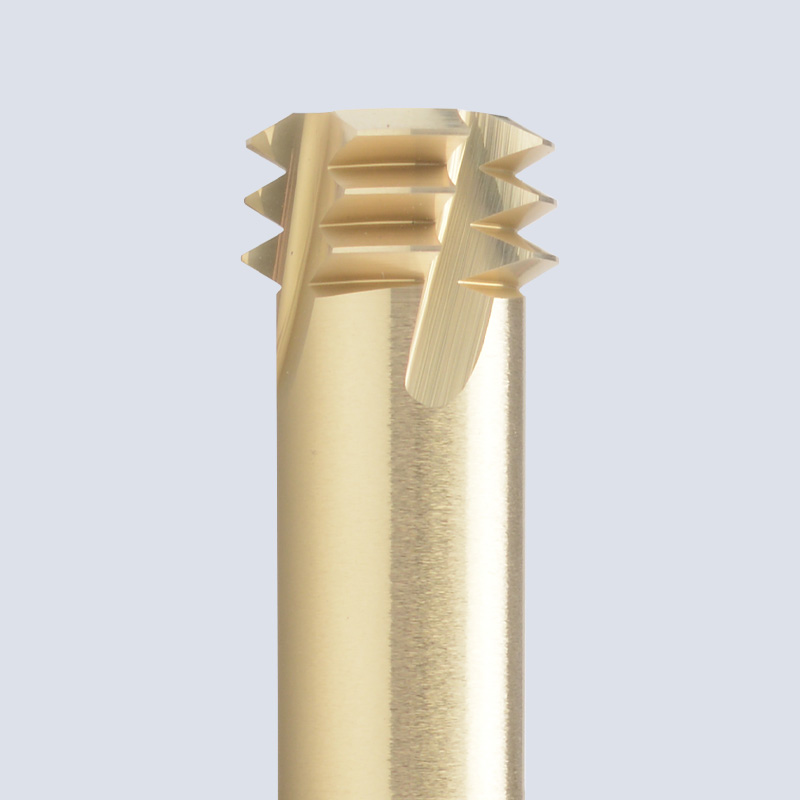

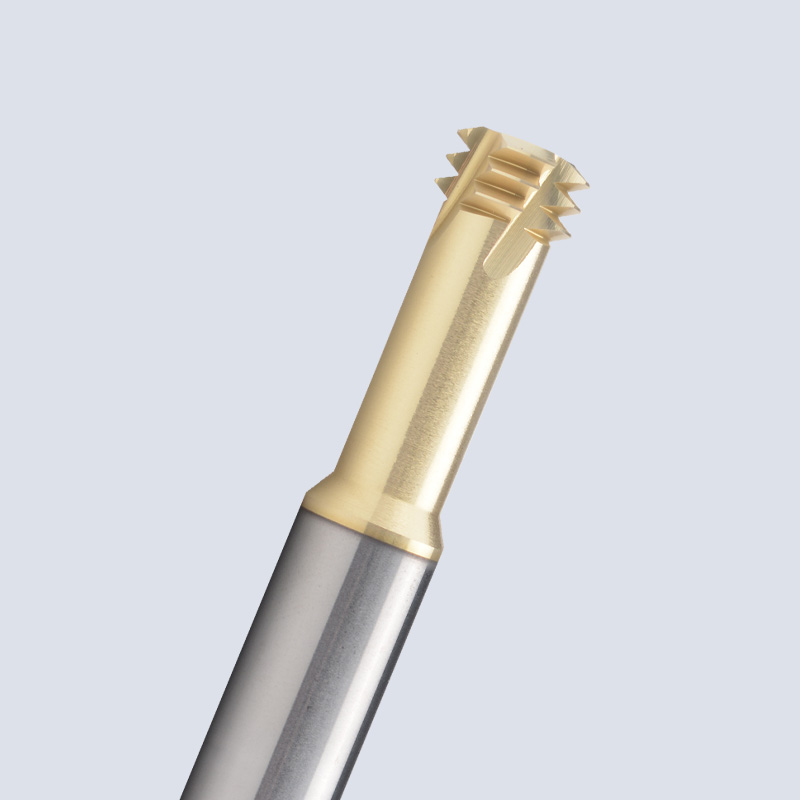

- Triple Tooth Design: This SDF-P series thread milling cutter features a triple tooth design, enabling multi-point cutting and significantly improving cutting efficiency. This design is particularly suitable for machining small-diameter threads, ensuring an efficient cutting process.

- Triple-Diameter Size: The milling cutter has a triple-diameter size, meaning its diameter is three times the standard diameter. This design increases the tool’s rigidity and strength, making it more stable during machining, reducing vibration and deformation, and improving machining accuracy.

- Оптимизированная геометрия: The optimized geometry and chip evacuation design ensure good chip evacuation, reducing cutting resistance and preventing chip buildup, ensuring smooth and consistent machining.

- Material and Coating:

- High-Quality Tungsten Carbide Base: Made from high-purity, high-performance tungsten carbide, this material has extremely high hardness and wear resistance, ensuring excellent performance and long service life under high-intensity and high-speed cutting conditions.

- ATNZ Coating: The surface is coated with an ATNZ coating specifically designed for high-temperature alloys and titanium alloys. This high-performance coating enhances the tool’s resistance to chip adhesion and high-temperature melting, significantly extending its service life and improving the surface finish quality of the machined materials.

- Function and Performance:

- High Rigidity and Strength: The triple-diameter size design increases the tool’s rigidity and strength, ensuring greater stability during machining, reducing vibration and deformation, and improving machining accuracy.

- High Wear Resistance: The combination of the ATNZ coating and high-quality tungsten carbide material ensures extremely high wear resistance, extending the tool’s service life.

- High Precision: Through precision grinding processes, the milling cutter achieves high geometric accuracy and consistency, enabling high-precision thread machining. Whether for roughing or finishing, it meets high standards of machining requirements.

- Efficient Chip Evacuation: The optimized geometry and chip evacuation design ensure good chip evacuation, reducing cutting resistance and preventing chip buildup, ensuring smooth and consistent machining.

- Поля приложений:

- Aerospace Components: Specifically suitable for machining critical aerospace components such as engine parts (turbine blades, combustion chambers, nozzles), structural components (wings, fuselage frames, landing gears), and other parts that require high-temperature and high-pressure resistance.

- Precision Mechanical Parts: Ideal for machining various precision mechanical parts, including fasteners (bolts, nuts, screws) and transmission systems (gears, bearings). These parts require high precision and reliable connection performance to ensure the safety and stability of aircraft.

- Other High-Requirement Applications: Beyond aerospace, this milling cutter is also suitable for other high-demand applications, such as research equipment, medical devices, military equipment, and key components in industrial automation equipment.

- Comprehensive Advantages:

- High Efficiency: The triple tooth design and optimized geometry ensure efficient cutting processes, increasing production efficiency.

- Long Service Life: The combination of high-quality tungsten carbide and the ATNZ coating significantly extends the tool’s service life, reducing the frequency of replacements and lowering production costs.

- High Precision: Precision grinding processes ensure the geometric accuracy and consistency of the milling cutter, meeting high-precision machining requirements.

- Stability: The triple-diameter size and optimized design ensure the tool’s stability and consistency during machining, reducing vibration and deformation, and improving machining accuracy.

Отзывы

Отзывов пока нет.