Professional Milling Tool Manufacturer – ShengDeFu

- Factory Overview:Founded in 2006, we have a team of about 100 specialized technicians and are equipped with 5-axis grinding machines from Sack, Anca, and Walter.

Premium Tools:The high-performance series uses GuhringK44 bars, while the general-purpose series uses GESAC bars.

Strict Quality Inspection:All products are inspected using German Zoller measurement systems during production.

- Expert Service: Experienced chief tool engineers and application engineers can address most customization challenges.

Employee Stability:The number of long-serving employees is stable, with 60% of the workforce having over 10 years of service.

As a Leading Tool Manufacturer – We Are Have

We specialize in the manufacturing of solid carbide end mills and drills, with over 18 years of experience.

We have invested in the latest German Zoller inspection systems to improve our finished product pass rate.

We have built an automated CNC grinding center, providing the highest precision and cost-effectiveness for the production of our metal drill tools.

High-Quality Rods From Famous Supplier

High-Quality Rods From Famous Supplier

German and Swiss CNC Machine Tools

German and Swiss CNC Machine Tools

German Zoller Inspection Systems

German Zoller Inspection Systems

Flexible and Versatile Customization Services

Flexible and Versatile Customization Services

Cost-effective and Fast Logistics Partnerships

Cost-effective and Fast Logistics Partnerships

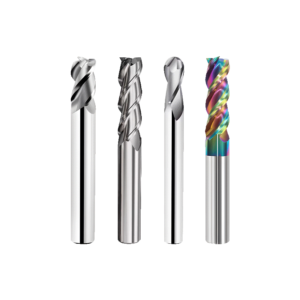

Customer Favorites – O Series Aluminum Milling Cutters

Solve Two Major Challenges in Aluminum Machining

Non-stick, chip breaking, smooth chip evacuation

High-glossmirror-likesurface

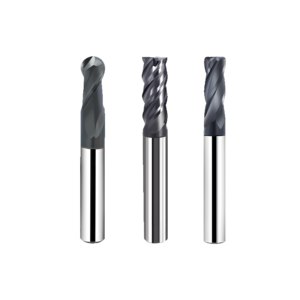

Premium Selection – M Series High-Performance Milling Cutters for Mold Steel

High Performance And Longlife

SDF High-Performance End Mills are ideally suited for machining HRC28 to HRC55 mold steel and precision applications, offering extended tool life. Tested to provide stable machining of HRC42 mold steel for over 10 hours.

Exceptional Precision and Superior Quality

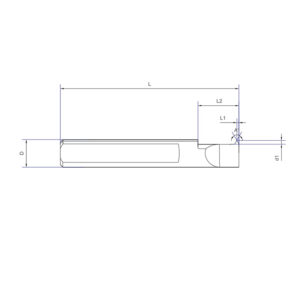

The SDF Spherical End Mill Series is engineered to deliver exceptional machining accuracy, achieving a precision level of 0.005 mm (5 microns). This remarkable precision ensures that even the most intricate and detailed parts can be machined with unparalleled accuracy and consistency.

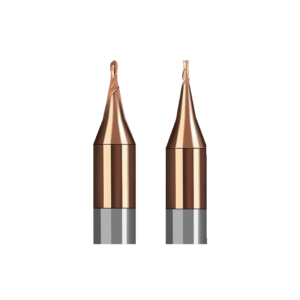

Top Picks – S Series Micro-Diameter Milling Cutter

0.1mm Micro-Diameter Milling Peak of Precision

The SDF Micro-Diameter End Mill Series showcases true technical prowess with its exceptional minimum diameter of 0.1 mm. This level of precision not only enables the handling of the most complex geometries and finest details but also ensures exceptionally high surface finish quality, even at such a minute size.

Star Products –Z Series High-Performance Drill Bit

Title: Oilfield/Mining Drill Bit Machining

Z-series bits are widely used in oil cone bits, mining cone bits, drilling tools, and shield tunneling tools, holding ~80% of China’s tooth hole processing tool market.

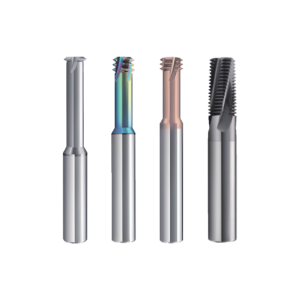

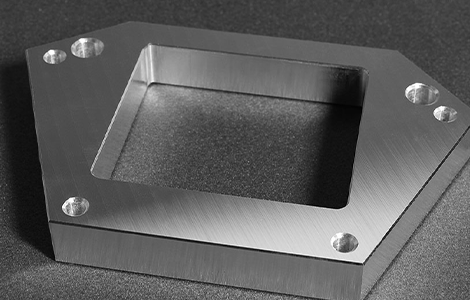

Innovation Highlights – Non-Standard Customized Cutting Tools

Independent Customization Department:

18 years of accumulated customization experience with over 50,000 cases, first-time trial success rate of 81.3%

Metal Cutting Field Full Coverage:

SDF’s non-standard customization services cover all areas of metal cutting, including turning, milling, hole making, and more. Customers specify their requirements, and SDF takes full responsibility for the machining results.

Explore our product categories

Our Delivery Process

Orders are shipped within 48 hours of receipt, using either FedEx or SF Express air transportation

Estimated Delivery Time

- Asia: 3-5 days

- North America: 5-9 days

- South America: 5-9 days

- Europe: 5-9 days

- Africa: 5-7 days

- Oceania: 9-12 days

- Note: Delivery times may vary due to customs efficiency and processing times in different countries

Client Testimonials