Features

Applications

Work Materials

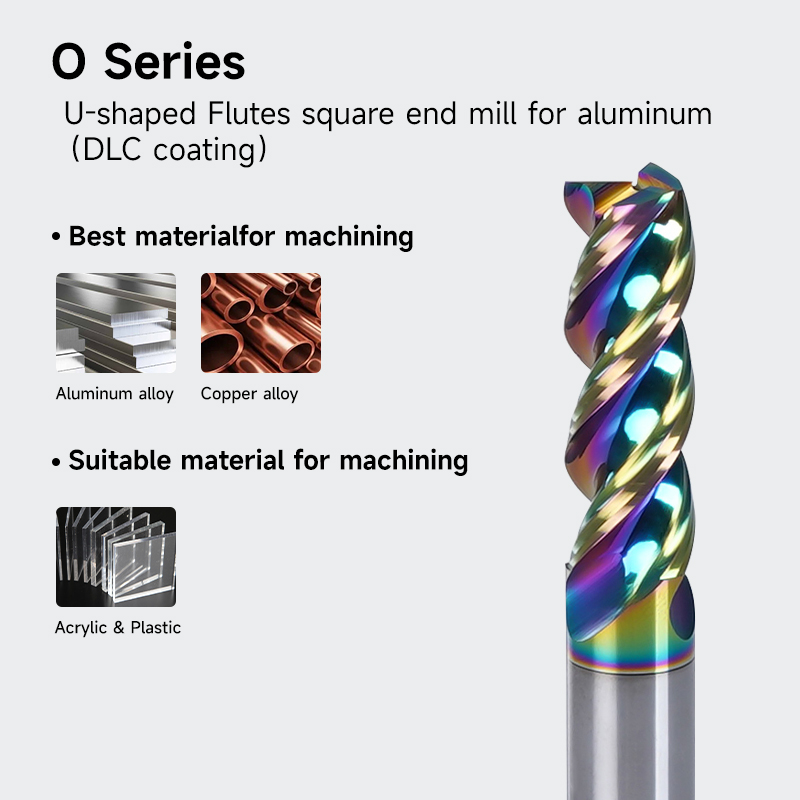

SDF-O Series 3-Flute Multi-Color Coated U-Groove Milling Cutter for Aluminum-Copper Alloys

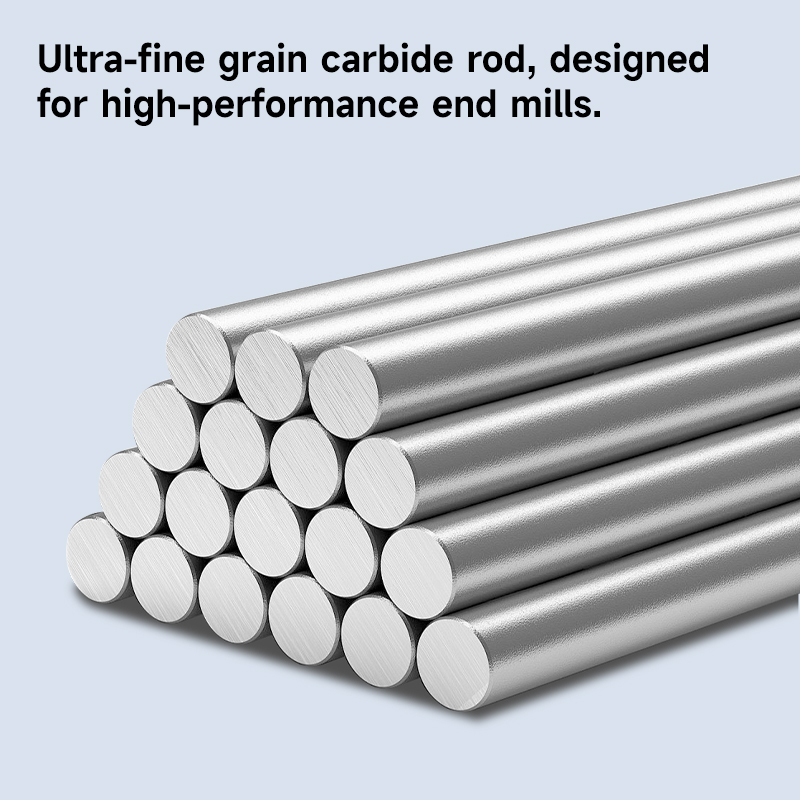

Material

- High-Quality Fine-Grain Micro-Particle Solid Carbide Material: Manufactured from high-quality fine-grain micro-particle solid carbide material, ensuring high hardness and toughness. This material selection not only guarantees the durability of the tool but also enhances its stability under high-speed cutting conditions.

Coating

- Multi-Color Coating: Utilizes multi-color coating technology, significantly enhancing the tool’s wear resistance and anti-adhesion properties, extending tool life and improving the surface finish of the workpiece. The multi-color coating also provides better visual recognition, making it easier for operators to identify and manage different types of tools.

Design

- Unique 3-Flute U-Groove Design: The 3-flute U-groove design ensures high metal removal rates and smooth chip evacuation, specifically designed for machining soft materials such as aluminum and copper. The U-groove design helps reduce the risk of chip clogging, improving machining efficiency.

- Optimized Cutting Edge Geometry: The cutting edge geometry is optimized to ensure consistent cutting forces and stable machining performance, enhancing the quality of the machined surface.

Functions

- High Metal Removal Rates: The 3-flute U-groove design enables the tool to achieve high metal removal rates during machining, particularly suitable for rapid processing of aluminum, copper, and other soft materials.

- Smooth Chip Evacuation: The optimized design ensures smooth chip evacuation, reducing the risk of chip clogging and improving both machining efficiency and tool life.

- Low Cutting Forces and Vibration: The 3-flute design effectively reduces cutting forces and vibrations during the machining process, ensuring a smooth and precise surface finish and dimensional accuracy.

- High Hardness and Toughness: High-quality fine-grain micro-particle solid carbide material ensures the tool has high hardness and toughness, capable of machining materials with hardness up to HRC 45°, suitable for various machining environments.

- Geometric Accuracy and Surface Quality: Precision ground on advanced German WALTER five-axis grinders, ensuring geometric accuracy and surface quality, guaranteeing consistent performance and tight tolerances.

Application Features

- Efficient Finishing: The 3-flute U-groove design allows the tool to achieve high metal removal rates during finishing operations while maintaining excellent surface finish.

- Complex Surface Machining: The U-groove design is particularly suitable for machining complex surfaces and contours, ensuring consistent cutting forces and stable machining performance.

- Thin-Wall and Complex Components: The smooth chip evacuation and reduced vibration make the tool suitable for machining thin-wall and complex components, ensuring dimensional accuracy and surface finish.

- Aluminum and Copper Alloy Machining: Specifically designed for machining soft materials such as aluminum and copper, widely used in industries such as electronics, automotive, and mold manufacturing.

Reviews

There are no reviews yet.