Features

Applications

Work Materials

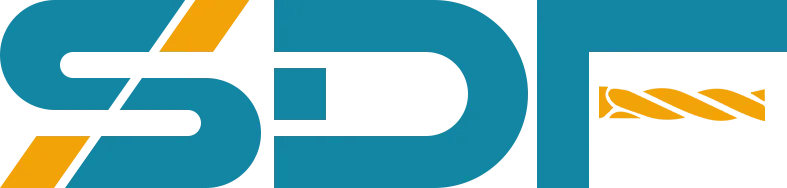

SDF-H Series Solid Tungsten Carbide High-Speed High-Hardness 2-Flute Ball Nose End Mill – ALTiSiN Coating

1. Material and Hardness:

The milling cutter is made from high-quality, ultra-fine grained tungsten carbide with exceptional hardness and wear resistance. This material maintains superior performance under high-intensity and high-speed cutting conditions, making it suitable for demanding machining environments. The high hardness and wear resistance ensure that the milling cutter retains excellent cutting performance over long periods of use, especially for machining hardened alloy steel, mold steel, and high-hardness steel materials (HRC60). Even when facing these extremely hard materials, the SDF-H series milling cutter provides stable cutting performance.

2. Design Features:

- Two-Flute Design: Provides efficient chip evacuation. Fewer flutes reduce cutting resistance and increase cutting speed, making it particularly suitable for high-speed machining. This design not only increases metal removal rates but also ensures a smoother cutting process, reducing vibration and noise.

- Ball Nose Design: Suitable for three-dimensional contouring and mold cavity machining, requiring high precision and smooth surface finishes. The ball nose design ensures accuracy and stability in complex surface machining.

- Advanced Grinding Process and Edge Treatment Technology: Utilizes advanced five-axis CNC grinding to ensure each cutting edge achieves micron-level precision, guaranteeing consistent performance and strict tolerance requirements. Special edge treatment technology enhances edge toughness and durability, effectively extending tool life.

- High-Performance ALTiSiN Coating: Surface-coated with ALTiSiN high-performance coating, offering superior wear and heat resistance, significantly improving cutting performance and tool life. The ALTiSiN coating also effectively reduces cutting temperature, minimizing thermal deformation of both the tool and workpiece, enhancing machining quality and tool longevity. Especially in high-temperature and high-pressure environments, the ALTiSiN coating provides additional protection, making it ideal for machining high-hardness materials.

3. Functionality and Performance:

- High Efficiency: The optimized two-flute design and special geometry allow the milling cutter to perform multiple cutting operations in a single pass, significantly improving cutting efficiency. This design reduces machining time and enhances machining quality.

- Long Life: High-quality ultra-fine grained tungsten carbide combined with advanced grinding processes, edge treatment technology, and ALTiSiN coating significantly extends tool life. This reduces replacement frequency, lowers production costs, and increases productivity.

- High Precision: Strict manufacturing processes ensure geometric precision and consistency, meeting high-precision machining requirements. Whether for roughing or finishing, it provides consistent and reliable results.

- Smooth Cutting: Optimized geometry and low-friction edge treatment ensure smooth and consistent cutting, reducing vibration and deformation, and improving machining accuracy and surface quality.

4. Cooling Method Adaptability:

The SDF-H series milling cutter is compatible with various cooling methods, including oil mist cooling, water cooling, and air cooling. Whether used in wet machining environments with oil mist cooling or dry machining with air cooling, this milling cutter maintains stable performance. Oil mist cooling effectively removes cutting heat, preventing tool overheating; water cooling helps rapidly cool down the tool, reducing thermal deformation; air cooling is suitable for applications where liquid coolants are not desired, avoiding coolant effects on the workpiece surface. The versatility in cooling methods enhances its performance across different machining environments.

5. Application Range:

The SDF-H series high-speed high-hardness 2-flute ball nose end mill is specifically designed for general machining of hardened alloy steel, mold steel, and high-hardness steel materials (HRC60) after heat treatment. It excels in mechanical manufacturing, mold manufacturing, aerospace, automotive manufacturing, and other fields. Its superior cutting performance and surface treatment technology ensure stable performance in complex shapes and high-precision requirements.

- Mechanical Manufacturing: Used for machining critical components such as gears and shafts, ensuring efficient material removal and high-precision surface quality.

- Mold Manufacturing: Used for machining complex shapes like mold cavities and templates, ensuring rapid material removal and achieving high-precision surface quality, meeting the strict requirements of mold manufacturing for precision and surface finish.

- Aerospace: Suitable for machining parts requiring high precision and reliability, such as aircraft engine components and structural pieces.

Automotive Manufacturing: Used for machining complex shapes in automotive components such as engine blocks and transmission housings, ensuring high precision and high-quality surface treatment.

Reviews

There are no reviews yet.