Features

Applications

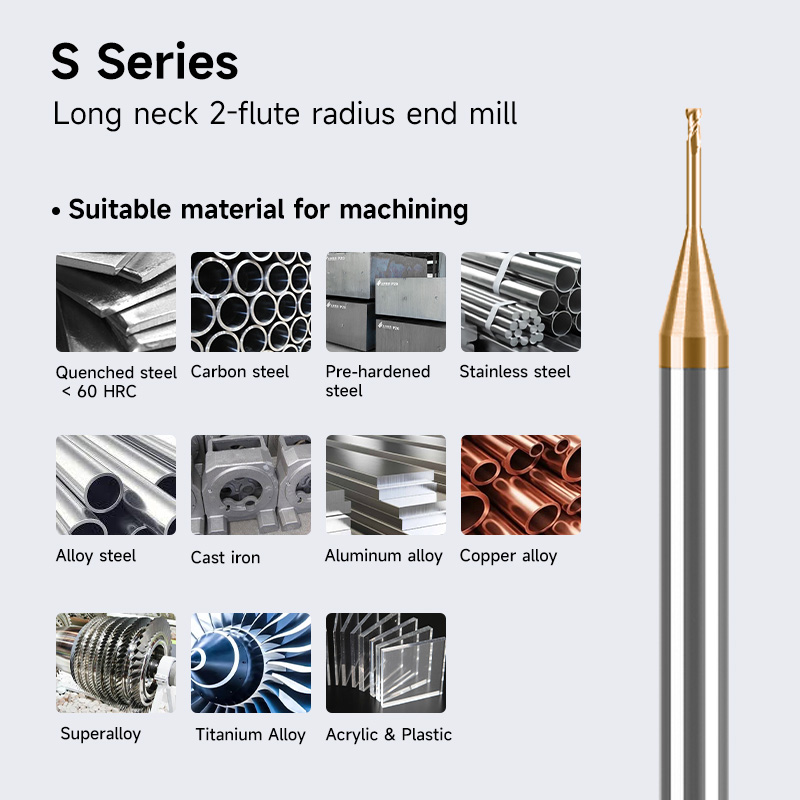

Work Materials

SDF-D Series Solid Carbide 2-Flute Deep Groove Radius End Mill – ALTiSiN Coating

The SDF-D series solid carbide two-flute deep groove round-nose end mills are high-performance tools specifically designed for extended cutting on hard materials such as HRC60° hardened steel. They are widely used in precision mold and component machining tasks. This product line not only features a series of advanced designs and technical characteristics but also demonstrates outstanding application value across multiple industries and complex component processing. Below is a detailed summary combining its technical features and specific applications:

Technical Characteristics and Advantages

- High-Quality Micrograin Tungsten Carbide Material:

- Manufactured from high-quality micrograin tungsten carbide blanks, ensuring extremely high hardness and toughness.

- Maintains stable cutting performance under high temperature and pressure conditions, providing durable and reliable machining experiences.

- Advanced Grinding Technology:

- Precision ground using German WALTER five-axis grinding machines, achieving ultra-high accuracy in both cutting diameter and shank diameter.

- Ensures optimal geometric accuracy and surface quality, significantly improving tool machining accuracy and service life.

- Unique Cutting Edge and Geometric Design:

- The unique two-flute design combined with optimized cutting edge geometry ensures high metal removal rates and smooth chip evacuation.

- Large chip flute design effectively prevents chip clogging, ensuring continuous and stable cutting processes, especially suitable for prolonged deep groove milling operations.

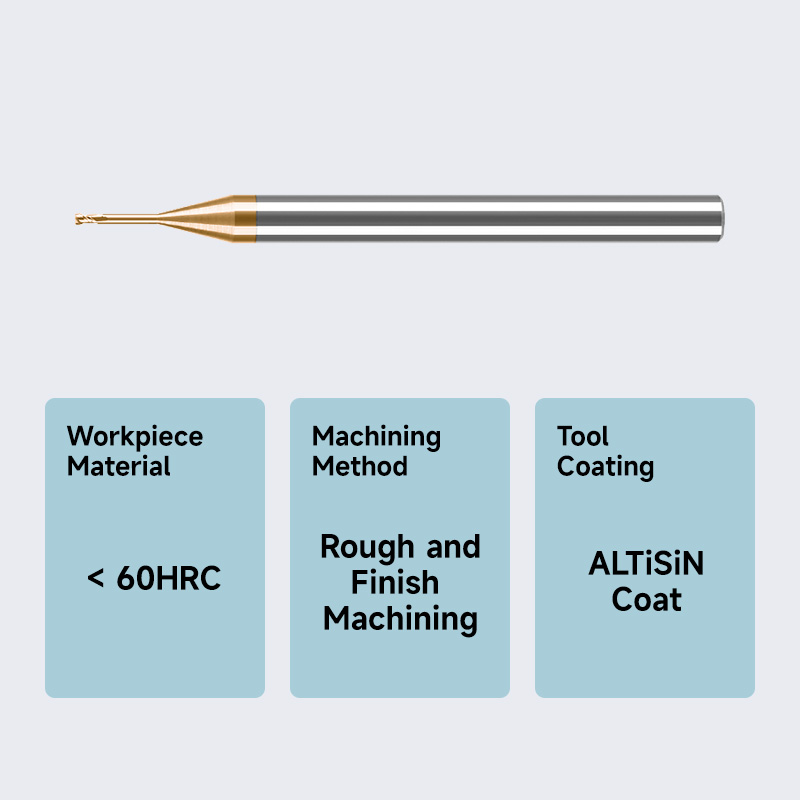

- ALTiSiN High-Wear-Resistant Coating:

- Coated with ALTiSiN high-wear-resistant coating, enhancing wear resistance and anti-adhesion properties, extending tool life.

- Improves the surface finish of machined parts, particularly suitable for long-duration cutting of hard materials, demonstrating high fracture resistance.

- Strict Quality Inspection:

- Each tool undergoes rigorous inspection using German ZOLLER equipment to ensure high performance and stability, meeting high-precision machining requirements.

Broad Applicability and Efficient Solutions

The SDF-D series end mills have high versatility, suitable for machining various materials including but not limited to hardened steels (HRC60°), mild steel, stainless steel, cast iron, and various high-hardness alloys. Their high precision and stability make them ideal for precision mold and component machining, capable of achieving complex geometries and high-precision requirements.

Detailed Application Scope

The SDF-D series plays a crucial role in multiple industries, especially in scenarios requiring high-precision deep slot machining:

- Aerospace Industry:

- Turbine Blades: Used in aerospace engine turbine blades to ensure aerodynamic performance and structural strength.

- Structural Components: Connection areas of large aircraft structures like fuselages and wings, achieving lightweight design while maintaining structural stability through deep groove milling.

- Automotive Manufacturing:

- Engine Block: High-precision machining of internal cooling water passages and lubrication channels to ensure thermal management and lubrication efficiency.

- Transmission Housing: Precise deep grooves between gearboxes and shaft holes to ensure smooth power transmission.

- Suspension System Components: High-strength and fatigue-resistant components like control arms and steering knuckles, relying on complex deep groove milling.

- Mold Manufacturing:

- Injection Molds: Processing flow channels and embedded parts in plastic molding molds to ensure precise fit and high-quality finished products.

- Die Casting Molds: Ensuring high wear resistance and dimensional accuracy in metal die casting molds.

- General Machinery Manufacturing:

- Pump Bodies and Valve Bodies: Fluid guiding channels in hydraulic and pneumatic systems to ensure proper function.

- Bearing Seats: Precise deep grooves for bearing installation positions in machinery to ensure accurate positioning and stable operation.

- Other Industries:

- Electronics: Manufacturing elements like heat sinks and enclosures, increasing heat dissipation area or forming specific shapes.

- Energy Sector: Special occasions like root sections of wind turbine blades and seals in nuclear power plants requiring deep groove milling.

Reviews

There are no reviews yet.