Features

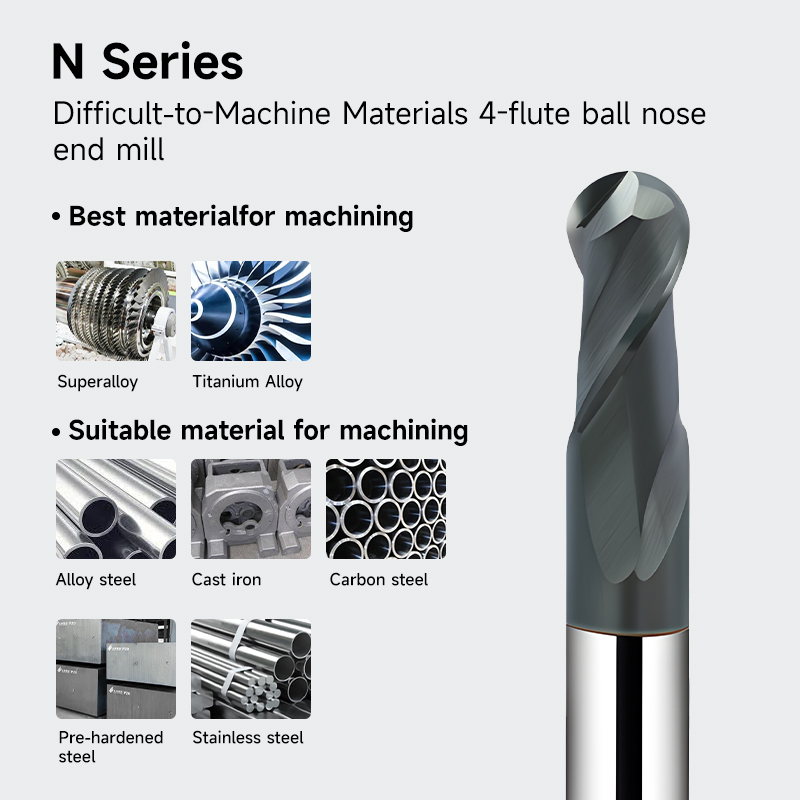

Applications

Work Materials

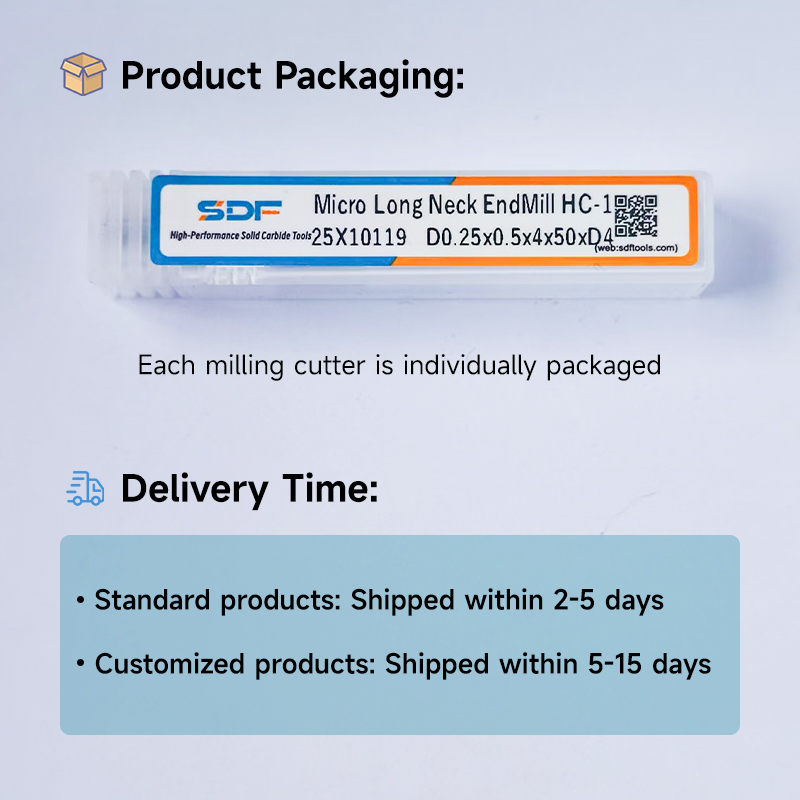

Product Description

Product Design

- 2-Flute Ball Nose End Mill:2-Flute ball nose end mill design with large chip clearance grooves ensures efficient chip evacuation, reduces chip clogging, and improves machining efficiency.

- Fine-Grain Micro-Particle Substrate:Made from fine-grain micro-particle substrate to ensure tool stability and high milling performance.

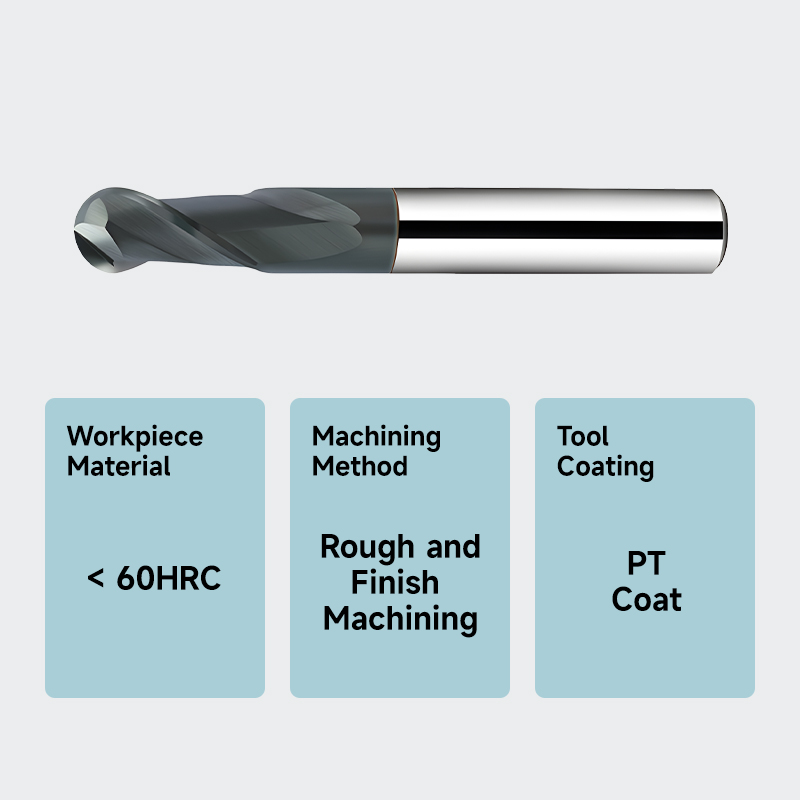

Coating Material

- Specialized PT Coating Material:Specialized PT coating material effectively reduces tool adhesion, extends tool life, and improves workpiece surface quality.

Function

- High Efficiency:Optimized for high-efficiency machining of superalloys and titanium alloys, with advanced tool geometry and coating technology ensuring efficient cutting in hard materials.

- Stability and Reliability:Provides stable and reliable performance, ensuring consistent quality and precision in demanding applications.

Suitable Milling Methods

- Suitable for Side Milling and Contour Milling:Particularly suitable for side milling and contour milling, capable of accurately machining complex 3D surfaces and side walls, ensuring surface finish and precision.

- Can Also Be Used for Slot Milling:Can also be used for slot milling, suitable for deep and narrow slots, ensuring good chip evacuation and stable cutting performance.

Application Scenarios

- Aerospace, Mold Manufacturing, and Other High-Demand Industries:Widely used in high-demand industries such as aerospace and mold manufacturing, suitable for difficult-to-machine materials like superalloys and titanium alloys.

Reviews

There are no reviews yet.