Features

Applications

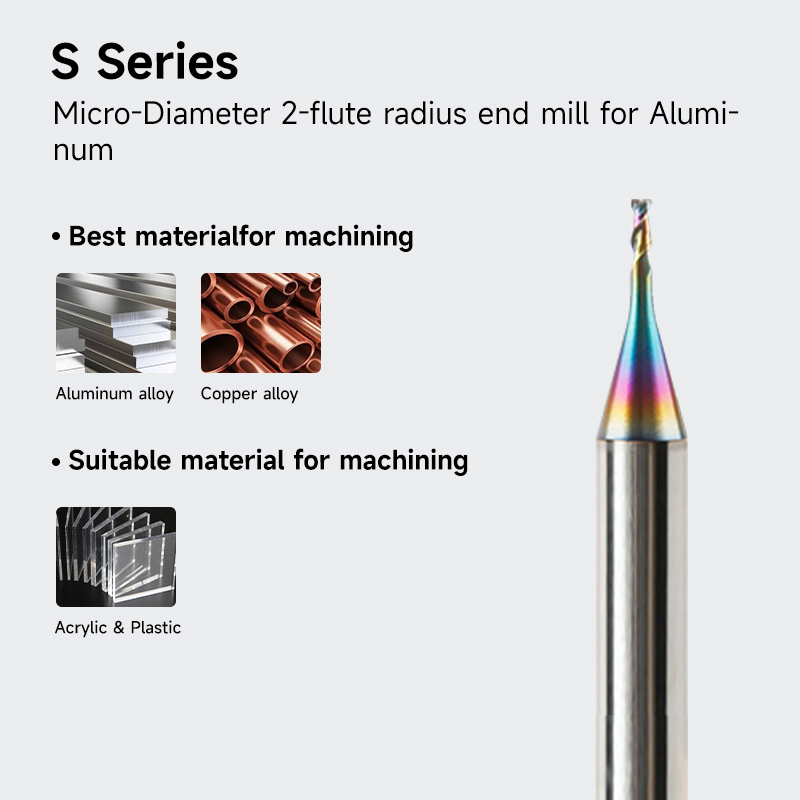

Work Materials

SDF-S Series Solid Carbide Micro-Diameter 2-Flute Radius Milling Cutter for Aluminum and Copper Alloys

Product Overview

The SDF-S Series Solid Carbide Micro-Diameter 2-Flute Radius Milling Cutter is a high-performance precision milling cutter specifically designed for machining copper and aluminum alloys. This series of tools is made from high-quality solid carbide material and features a fine diameter and optimized radius R angle design, suitable for the efficient processing of micro and precision parts. The highly wear-resistant DLC coating significantly enhances the tool’s wear resistance and anti-adhesion properties, extending tool life and improving surface finish. Advanced German WALTER five-axis grinders and ZOLLER inspection equipment ensure the tool’s geometric accuracy, surface quality, and consistent performance.

Product Features

- Specifically Designed for Copper and Aluminum Alloys:

- Made from high-quality solid carbide material, ensuring high hardness and toughness.

- Optimized geometry and micro-diameter design, particularly suitable for precision machining of copper and aluminum alloys.

- Fine Diameter:

- The micro-diameter design enables the tool to perform fine and complex machining, especially suitable for micro and precision parts.

- Achieves higher machining accuracy and finer surface finishes.

- Optimized Radius R Angle:

- The optimized radius R angle design ensures good metal removal rates and smooth surface quality when machining surfaces and contours.

- Reduces cutting forces and vibrations, improving machining stability and surface finish.

- Highly Wear-Resistant DLC Coating:

- Utilizes a highly wear-resistant DLC (Diamond-Like Carbon) coating, significantly enhancing the tool’s wear resistance and anti-adhesion properties.

- Extends tool life, improves surface finish, reduces heat generation during cutting, and increases cutting efficiency.

- Geometric Accuracy and Surface Quality:

- Precision ground on advanced German WALTER five-axis grinders, ensuring geometric accuracy and surface quality.

- Guarantees consistent performance and tight tolerances, meeting the requirements of high-precision machining.

- High and Stable Quality Inspection:

- Inspected using German ZOLLER measuring equipment, with each tool individually inspected, ensuring high and stable tool quality.

Milling Methods

- Efficient Cutting: The optimized radius R angle design and micro-diameter design enable the tool to achieve efficient cutting while maintaining high precision and good surface quality.

- Precision Machining: Suitable for the machining of micro and precision parts, capable of performing fine and complex machining, particularly appropriate for applications requiring high precision and high surface quality.

Application Scenarios

- Precision Machining of Copper and Aluminum Alloys:

- Widely used in industries such as electronics, automotive, and mold manufacturing, particularly suitable for the precision machining of copper and aluminum alloy parts.

- Ensures high precision and good surface quality, meeting the demands of high-end manufacturing.

- Small and Precision Part Machining:

- The micro-diameter design allows the tool to perform fine and complex machining, especially suitable for small and precision parts.

- Appropriate for high-precision and complex component machining, such as miniature electronic components and precision mechanical parts.

- Complex Surface Machining:

- The optimized radius R angle design is particularly suitable for machining complex surfaces and contours, ensuring consistent cutting forces and stable machining performance.

- Appropriate for high-precision and complex component machining, such as mold cavities and aerospace parts.

- Efficient Cutting:

- The optimized geometry and highly wear-resistant DLC coating enable the tool to achieve efficient cutting while maintaining high precision and good surface quality.

- Increases production efficiency, reduces production costs, and is suitable for high-volume production environments.

Reviews

There are no reviews yet.