Features

Applications

Work Materials

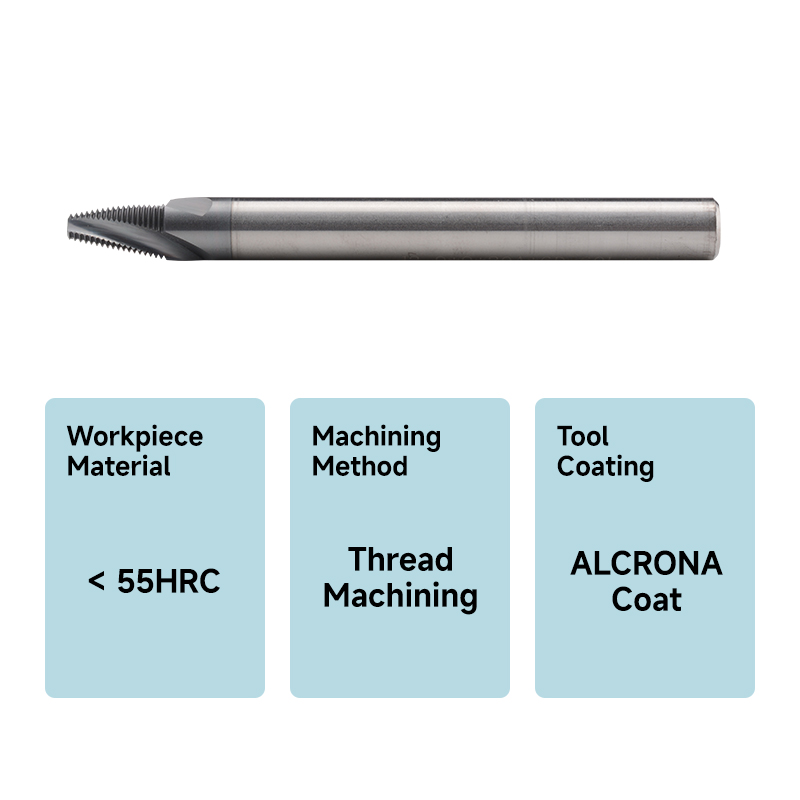

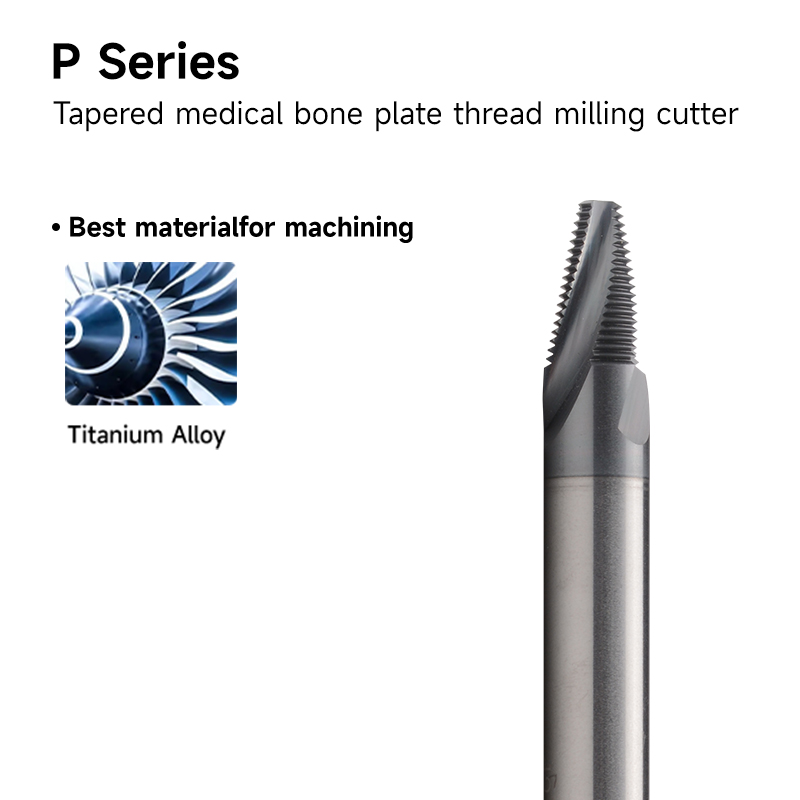

SDF-P Series Tungsten Carbide Tapered Medical Bone Plate Thread Milling Cutter for Titanium – ALCRONA Coating

- Material and Hardness:

- This milling cutter is made from high-quality tungsten carbide, ensuring exceptional hardness and wear resistance. Tungsten carbide maintains excellent performance under high-intensity and high-speed cutting conditions, making it suitable for demanding machining environments. The high hardness and wear resistance of the material ensure that the tool retains its cutting performance even after prolonged use.

- Design Features:

- Tapered Design: This milling cutter features a tapered design, specifically tailored for threading medical bone plates. The tapered design better accommodates complex shapes and high-precision requirements, ensuring uniform and consistent thread formation.

- Multi-Flute Structure: The tool has a multi-flute design, where each flute is responsible for cutting a portion of the thread. Through multiple passes, the entire thread is gradually completed, ensuring uniformity and consistency.

- Optimized Geometry: The geometry of the milling cutter is optimized to ensure efficient chip evacuation and minimal cutting resistance. This not only enhances cutting efficiency but also reduces wear on both the tool and the workpiece.

- Coating Technology:

- ALCRONA Coating: The surface is coated with ALCRONA coating, specifically designed for machining titanium alloys. The ALCRONA coating provides high hardness, excellent wear resistance, and superior thermal stability, significantly enhancing the cutting force and tool life. The coating effectively reduces cutting temperatures, minimizing thermal deformation of the tool and workpiece, and improving machining quality and tool life.

- Application Range:

- Suitable Materials: Specifically designed for machining titanium alloys. Titanium alloys are widely used in the medical field due to their lightweight, high strength, and excellent biocompatibility, particularly in orthopedic surgeries for bone plates and implants.

- Industry Applications: Widely used in the medical industry, especially for threading bone plates in orthopedic surgeries. These components require high precision and reliable connection performance to ensure surgical success and patient recovery.

- Function and Performance:

- High Precision: Strict manufacturing processes ensure the geometric accuracy and consistency of the milling cutter, meeting the high-precision requirements for medical components. Whether for roughing or finishing, it provides consistent and reliable results.

- Efficient Cutting: Optimized geometry and cutting edge design ensure efficient chip evacuation and minimal cutting resistance, reducing vibration and deformation, and improving machining precision and surface quality.

- Long Life: The combination of high-quality tungsten carbide material and advanced ALCRONA coating significantly extends the tool’s lifespan. This reduces the frequency of tool changes, lowers production costs, and improves overall productivity.

- Biocompatibility: Optimized for titanium alloys, ensuring that the machined bone plates have excellent biocompatibility, meeting the stringent standards of the medical industry.

- Application Scenarios:

- Orthopedic Surgery: Suitable for threading bone plates in orthopedic surgeries, ensuring reliable connections and biocompatibility. For example, fracture fixation plates, spinal implants, etc.

- Medical Device Manufacturing: Suitable for precision threading in medical device manufacturing, such as surgical instruments and implants, where high quality and precision of threads are critical.

- Research and Development: Suitable for research and development projects in the medical field, particularly in the development of new medical devices and implants, where high-precision and high-quality threading are required.

Reviews

There are no reviews yet.