Innovative Technology Leads a New Trend in Mechanical Machining, Achieving Superior Surface Finish Without Coolant End mills

Setting New Industry Standards with Globally Unique Unequal Helix Design End Mills

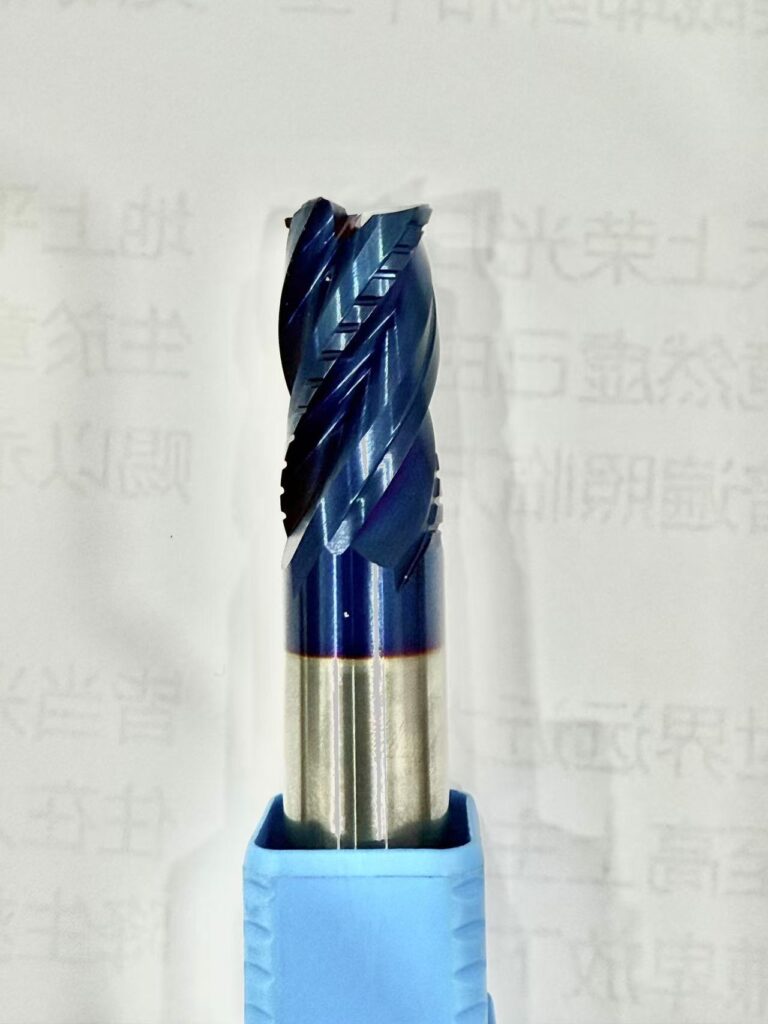

In the field of mechanical machining, every manufacturer strives for higher efficiency and superior machining quality. As a pioneer in this sector, Sindelfingen has launched a new high-performance end mill that not only combines roughing and finishing capabilities but also achieves unprecedented material handling performance. This end mill is especially suited for milling difficult-to-machine materials, providing fine surface finishes despite its robust appearance, thanks to our globally unique unequal helix design.

Breaking Limits: Stable Machining of HRC54 Stainless Steel for Over 6 Hours

Through rigorous internal testing, our end mills can stably machine stainless steel with hardness up to HRC54 for over 6 hours continuously. Under extreme conditions, it can efficiently process materials with hardness as high as HRC62 for 1 hour without the use of coolant, while maintaining surface finish quality. This outstanding performance makes the product an ideal choice for machining high-hardness materials.

Reducing Vibration and Noise, Enhancing Machining Stability

This end mill excels not only under extreme conditions but also in regular machining. By reducing vibration and noise during processing, it enhances overall machining stability, ensuring better surface quality and longer tool life. Additionally, enhanced chip control further improves operational safety and convenience.

Industry-Leading Innovative Technology

Featuring a globally unique unequal helix design, this technology was independently developed by the Sindelfingen team and patented. By optimizing the distribution of helix angles, it effectively distributes cutting forces, reduces the possibility of thermal deformation, and ensures long-term stable operation. This unique design significantly slows down tool wear, extending its service life.

User Feedback and Market Response

Since its launch, this end mill has received enthusiastic market response, with users praising its exceptional performance. Both large manufacturing enterprises and small workshops have highly commended the reliability and efficiency of this product. Many customers report noticeable improvements in production efficiency and product quality after adopting this end mill.

Conclusion

In today’s increasingly competitive global environment, technological innovation is at the heart of corporate development. With its deep technical expertise and continuous R&D investment, Sindelfingen has successfully introduced this milestone end mill. We believe that as more users apply this product, it will profoundly impact the entire mechanical machining industry. If you are looking for an end mill that can meet complex challenges and provide superior performance, do not miss this option from Sindelfingen.

This article not only introduces the key features of the product but also highlights its outstanding performance in practical applications and potential impacts on future industry development. The article is structured following SEO principles to attract Google search users’ attention and encourage them to click and read. Should there be any adjustments or additional content needed, please feel free to inform us!