Features

Applications

Work Materials

SDF-A Series Specialized Internal Cooling Deep Hole Carbide Drill for Cast Iron and Steel with DH Coating

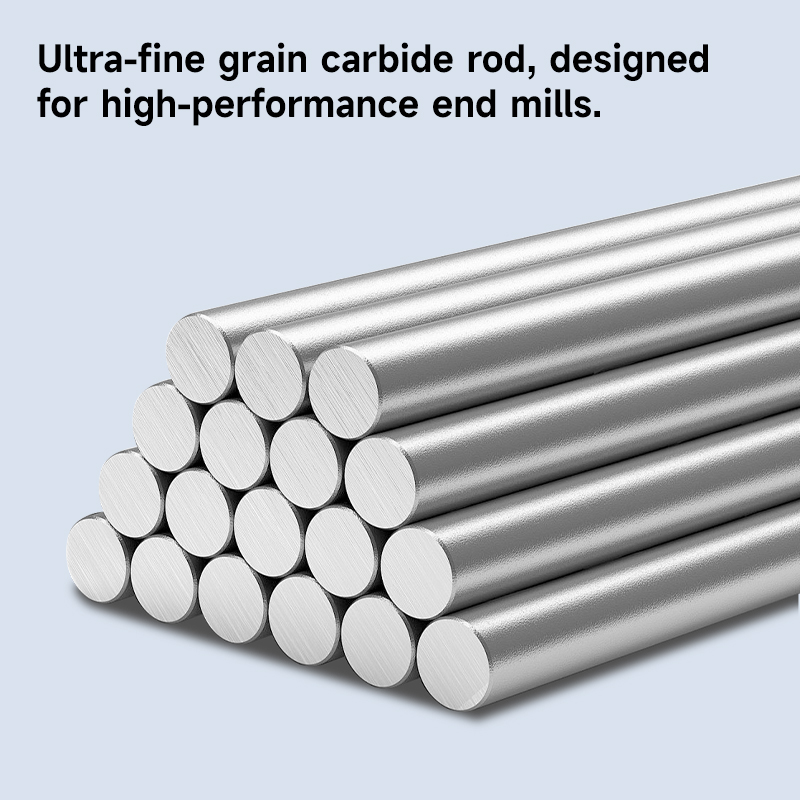

Product Material

The SDF-A series drill is manufactured from solid tungsten carbide, renowned for its exceptional hardness, superior wear resistance, and compressive strength. Compared to high-speed steel, tungsten carbide exhibits higher heat resistance, maintaining its geometric shape and cutting performance even at elevated temperatures, making it ideal for machining high-hardness materials such as cast iron and steel. Additionally, tungsten carbide offers excellent chemical stability, minimizing reactions with the workpiece material and reducing tool wear.

Design Features

- Internal Cooling System: Designed with internal coolant channels that ensure coolant reaches the cutting zone directly, effectively lowering cutting temperatures, improving chip evacuation, and minimizing tool damage caused by overheating.

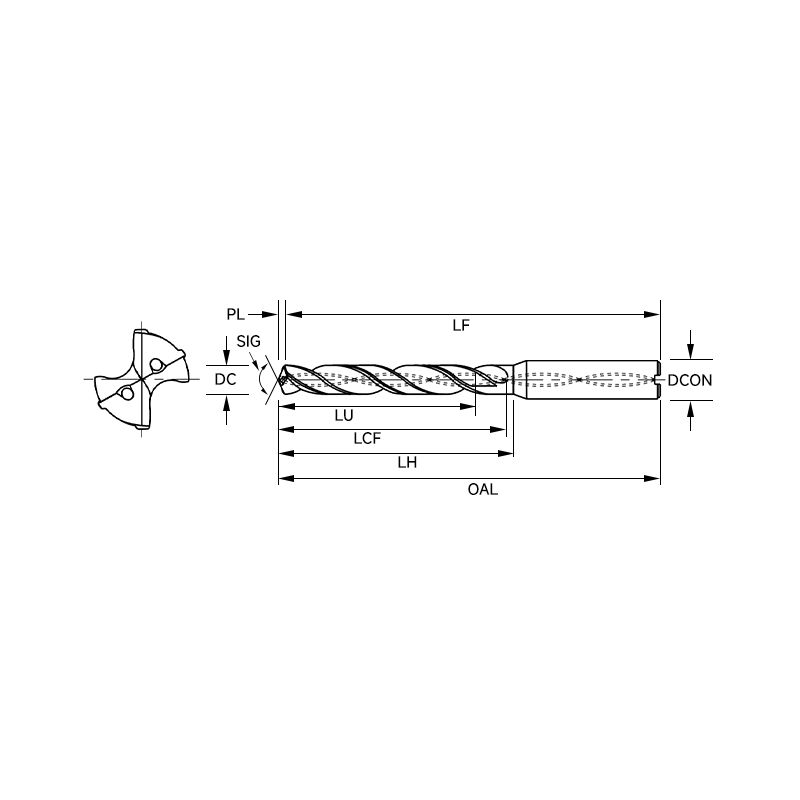

- Optimized Geometric Structure: The drill point angle is meticulously engineered for optimal entry; the helix angle is selected to balance efficient chip removal and the distribution of cutting forces, reducing vibration risks and ensuring straight and smooth drilling.

- Land Treatment: Precise control over land width and position further improves drill stability, especially during deep hole drilling.

- Size Range: Available in diameters ranging from D3mm to 20mm, supporting a variety of machining tasks, with a maximum drilling depth reaching up to 12 to 40 times the drill diameter, suitable for deep-hole applications.

Coating Technology

- DH Coating: This is a specialized multi-layer composite coating developed to enhance drill performance. The DH coating not only provides outstanding lubrication, reducing friction coefficients, but also enhances the drill’s oxidation resistance and wear resistance. Under high-temperature conditions, the coating remains stable, extending tool life and improving surface finish quality.

Functional Advantages

- High Precision Machining: The drill achieves hole diameter tolerances of H8 to H9, ensuring high dimensional accuracy suitable for precision part manufacturing.

- Efficient Chip Removal: The internal cooling system significantly improves chip evacuation, reducing chip accumulation and avoiding issues caused by poor chip removal.

- Long Service Life: The combination of DH coating and the tungsten carbide base ensures outstanding performance under continuous heavy-duty operations, extending tool life.

Application Areas

- Wide Applicability: The SDF-A series drill is particularly suited for machining various types of steels and cast iron materials, commonly found in specialized machinery, mold manufacturing, automotive part production, and energy equipment manufacturing.

- Complex Conditions Adaptability: It is designed for conventional drilling, intersecting holes, and angled surfaces, ensuring stable performance across different machining environments.

- Precision Requirements: It meets H8 to H9 class hole diameter tolerance requirements, ensuring high dimensional accuracy and roundness, suitable for precision mechanical parts manufacturing.

Summary

The SDF-A series specialized internal cooling deep hole carbide drill with DH coating integrates advanced material science, innovative design, and efficient coating technology into a high-end tool. Tailored to address the challenges of high-precision machining under complex working conditions, it performs exceptionally well under continuous heavy-duty operations and complex conditions. This drill is an ideal choice for those pursuing high-quality and efficient machining, designed to provide superior machining performance and reliability, significantly enhancing production efficiency and product quality.

Reviews

There are no reviews yet.