Features

Applications

Work Materials

SDF-G Series Solid Tungsten Carbide General-Purpose 4-Flute Radius End Mill with ALCRONA Coating, HRC45

- Material and Hardness: The milling cutter is made from solid tungsten carbide, ensuring extremely high hardness and excellent wear resistance. Tungsten carbide maintains stable performance under high-intensity and high-speed cutting conditions, suitable for demanding machining environments. This material not only extends the tool’s lifespan but also ensures consistent cutting performance over extended use. It is particularly suited for applications requiring high hardness and wear resistance.

- Design Features:

- Four-Flute Structure: Each flute handles a portion of the cutting work, gradually completing the machining process to ensure efficient material removal and superior surface quality. The four-flute design increases cutting speed and feed rate while reducing vibration and deformation, enhancing machining accuracy.

- Optimized Geometry: The geometry of the milling cutter is optimized to ensure efficient chip evacuation and minimal cutting resistance. This improves cutting efficiency and reduces wear on both the tool and the workpiece, extending tool life.

- Radius Cutting Edge: The specially designed radius cutting edge (Radius End Mill) provides smooth material transition, reducing stress concentration. It is ideal for machining complex radii and fillets, offering better surface finish and higher machining precision.

- Coating Technology:

- ALCRONA Coating: The surface is coated with ALCRONA coating, providing high hardness, low friction, and superior thermal stability, significantly enhancing cutting force and tool life. The ALCRONA coating effectively reduces cutting temperatures, minimizes thermal deformation, and improves machining quality and tool life. Additionally, the coating offers excellent lubrication properties, further reducing cutting resistance.

- Suitable Materials:

- Pre-Heat Treatment Steel Processing: Designed for HRC45, this milling cutter is particularly suitable for pre-heat treatment machining of steels, handling initial forming requirements for various types of steel. This hardness range requires tools with high toughness and wear resistance, which this end mill fully meets. It can be used for roughing and semi-finishing before heat treatment to ensure smooth subsequent processes.

- Non-Ferrous Materials: Widely applicable for machining non-ferrous materials such as aluminum alloys, copper alloys, and other soft metals, as well as non-metallic materials like plastics, demonstrating excellent versatility. Its broad applicability makes this milling cutter an ideal choice for processing multiple materials.

- Processing Precision:

- Suitable for Roughing and Finishing: This milling cutter is not only suitable for roughing but also for finishing operations, making it versatile for applications that require rapid material removal and high surface quality. Its optimized geometry and four-flute design ensure high efficiency in roughing and stability in finishing. Whether removing large amounts of material or achieving fine finishes, this milling cutter performs exceptionally well.

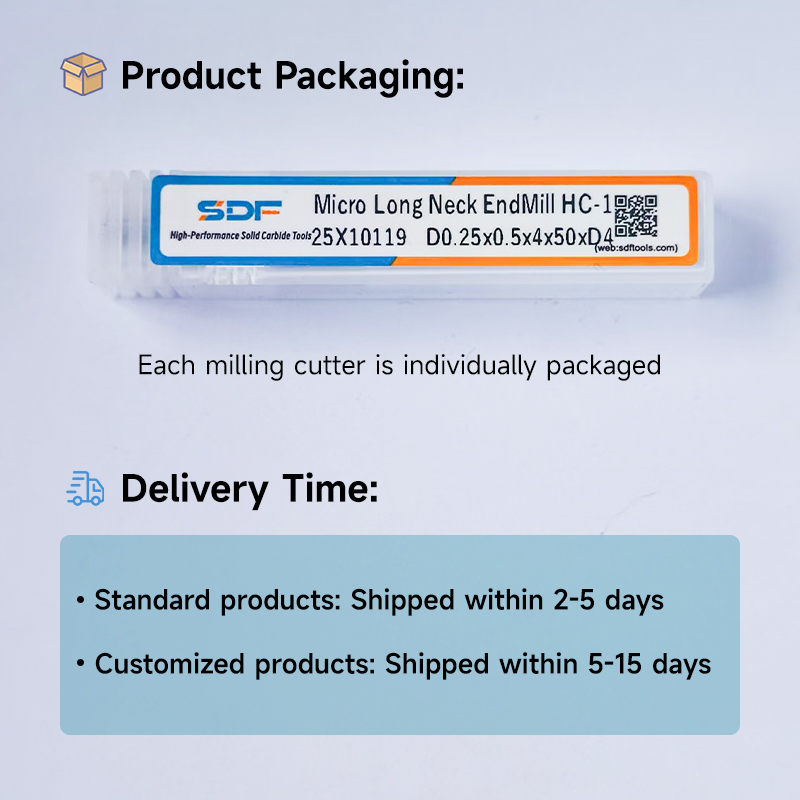

- Specifications and Models:

- Comprehensive Range of Specifications: Available in various sizes and shapes to meet different machining needs. Suitable models can be found for both roughing and finishing, ensuring flexibility and efficiency in the machining process. The wide range of specifications makes this milling cutter adaptable to diverse industry requirements.

- Application Fields:

- Mechanical Manufacturing: Ideal for roughing and finishing of various mechanical parts such as valve bodies, joints, and other critical components. These parts require efficient material removal and high-precision surface quality to ensure smooth subsequent processes.

- Aerospace: In the aerospace industry, this milling cutter can be used for both roughing and finishing of high-precision and complex-shaped components, meeting strict precision and reliability requirements. For example, engine components and structural parts.

- Automotive Manufacturing: Suitable for roughing and finishing of automotive components such as engine blocks and transmission housings, where processing efficiency and surface quality are crucial.

- Mold Manufacturing: Ideal for roughing and finishing in mold manufacturing, such as mold cavities and templates. These components require rapid material removal and high-precision surface quality to ensure smooth follow-up finishing processes.

- Special Application Features:

- Advantages of Radius Cutting Edge: The radius cutting edge design is particularly suitable for machining radii and fillets, reducing stress concentration and preventing cracks and fractures. This design enhances the overall strength and durability of the workpiece. It is especially suitable for applications requiring smooth transitions and high-precision surfaces, such as precision mechanical parts and aerospace structures.

- Combining Efficient Material Removal with High Precision: Due to its four-flute design and optimized geometry, this milling cutter can efficiently remove large amounts of material while maintaining high precision and excellent surface quality. This makes it ideal for both mass production and high-precision machining requirements.

Reviews

There are no reviews yet.