Features

Applications

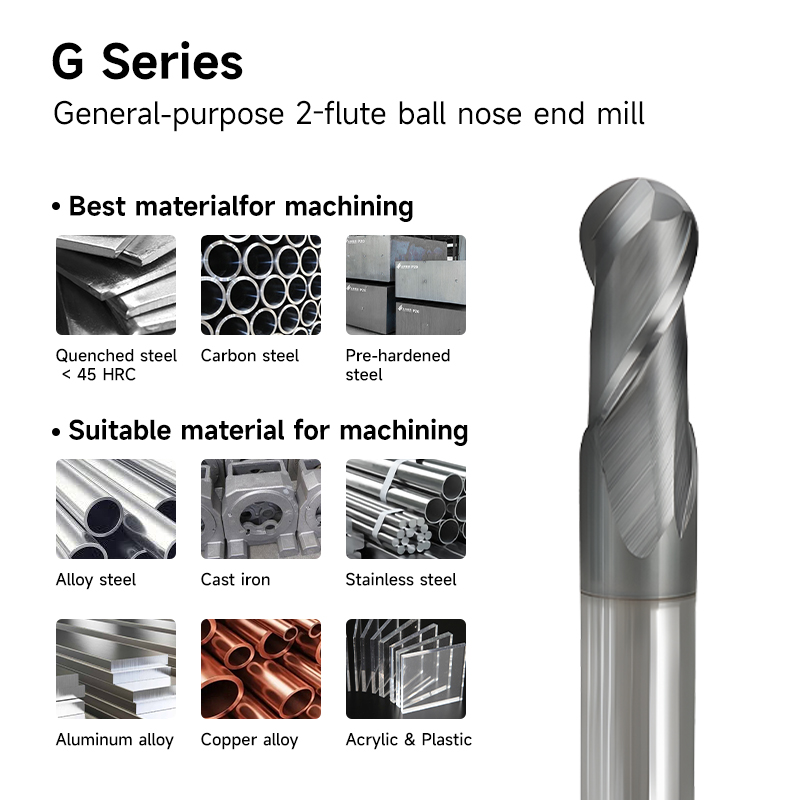

Work Materials

SDF-G Series General Purpose 2-Flute Solid Carbide Ball Nose End Mill – ALCRONA Coating

- Material Compatibility: The SDF-G series ball nose end mill is suitable for machining all types of steel before heat treatment and is also applicable to non-steel materials such as aluminum. Its superior cutting performance ensures efficient processing across different materials. Whether it’s high-strength steel, stainless steel, or aluminum alloys, this end mill provides stable cutting results and excellent surface quality.

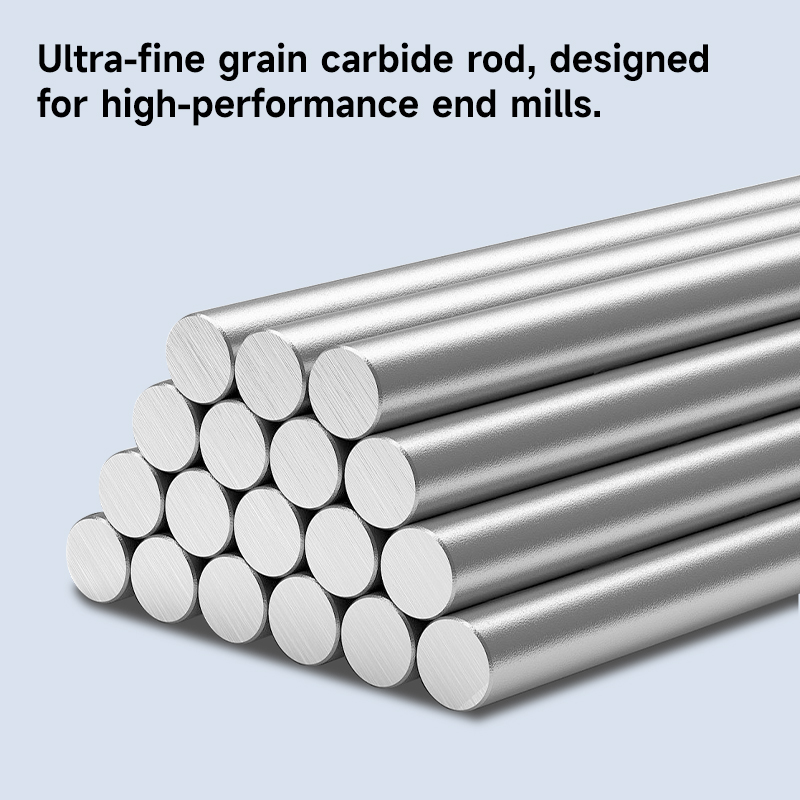

- High-Performance ALCRONA Coating: Surface-coated with high-performance ALCRONA coating, it offers exceptional wear and heat resistance, significantly improving tool life and cutting efficiency. This coating effectively reduces cutting temperature, minimizes thermal deformation of both the tool and workpiece, and extends tool life. Additionally, the ALCRONA coating enhances the tool’s anti-adhesion properties, preventing chip build-up on the tool and further improving machining accuracy and surface finish.

- Two-Flute Design and Its Advantages: Featuring a two-flute design, it ensures efficient chip evacuation and lower cutting forces, making it particularly suitable for high-speed machining. This design increases metal removal rates while reducing vibration and noise, ensuring a smooth cutting process. The ball nose design makes this end mill ideal for three-dimensional contouring and complex surface machining, achieving high precision and smooth surface finishes. The two-flute design also provides better cutting stability and higher cutting speeds, suitable for fine machining and complex shapes.

- Comprehensive Specifications: The SDF-G series offers various specifications and models, meeting diverse machining requirements and suitable for a wide range of industrial applications. From roughing to finishing, this end mill delivers consistent and reliable performance. The extensive range of options allows users to select the most appropriate tool based on specific machining needs, ensuring optimal machining results and production efficiency.

- High Precision and Stability: Strict manufacturing processes ensure micron-level precision for each cutting edge, providing high-precision and stable cutting results, especially for complex shapes and high-precision requirements. Advanced grinding and edge treatment technologies enhance the durability and resilience of the cutting edges, effectively extending the tool’s service life. Whether in mass production or complex part machining, this end mill offers reliable solutions, ensuring efficient, stable, and high-quality cutting performance.

- Wide Application Range: The SDF-G series ball nose end mill finds extensive application in multiple high-precision machining fields, particularly where complex geometries and high precision are required. Specific applications include:

- Precision Mold Manufacturing: Used for machining complex mold cavities, templates, etc., ensuring rapid material removal and achieving high-precision surface finishes, meeting the stringent requirements of mold manufacturing for accuracy and surface finish.

- Aerospace: Suitable for machining high-precision and reliability-critical components such as turbine blades, structural parts, etc., ensuring precise and stable machining of complex geometries. For example, machining the three-dimensional contours and complex surfaces of turbine blades.

Automotive Manufacturing: Used for machining automotive components like engine blocks, transmission housings, etc., ensuring high precision and high-quality surface finishes. The ball nose end mill is especially suitable for three-dimensional contour machining, such as the fine contours of cylinder heads and the complex shapes of intake and exhaust ports.

Reviews

There are no reviews yet.