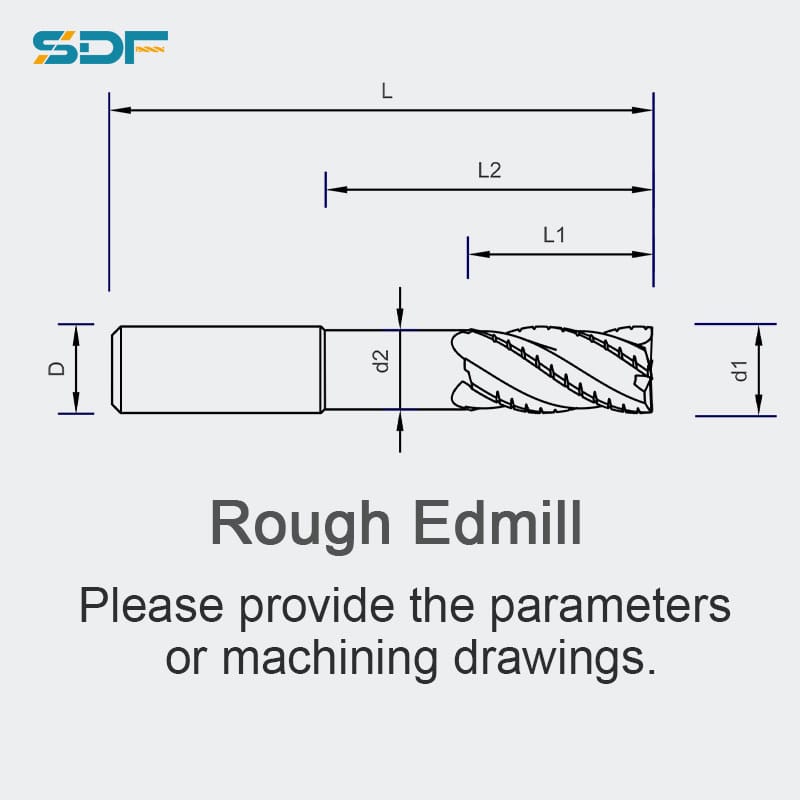

We can provide customized tooling solutions for complex workpiece machining. We tailor the design of the tool material, cutting edge geometry, and angles to enhance machining precision, reduce processing steps, and lower the product scrap rate. Simply present your requirements, and our professional engineers will work with you to meet your needs.

Customization Process for Non-Standard Cutting Tools

- First, clearly define your requirements. Generally, the main purpose of customizing non-standard cutting tools is to reduce production time and lower production costs. This may also be necessary for very complex workpieces that require special tools for cutting.

- Once you have a specific need, click “Contact Us” and fill in your detailed requirements in the form. If you have tool drawings or drawings and photos of the parts to be machined, please upload them to the contact form.

- After receiving your information, our engineers will typically contact you within 12 hours to discuss your detailed requirements.

- Our engineers will provide a complete solution and drawings, along with a quote based on your requirements and quantity, including details such as production time and shipping time.

- Once you agree to our proposal and accept the price, the engineer will provide precise drawings. After you approve the drawings, we will generate an electronic contract.

- After signing the contract, you will need to pay the actual cost. We support various forms of international payment, including platform-secured transactions.

- Once production is complete, we will ship the tools according to the agreed-upon shipping method, typically using sea or air freight.

Service: After receiving the tools, our engineers will guide you on the usage precautions. If the tools do not meet the expected performance during use, we will cover the resharpening or replacement costs.

Reviews

There are no reviews yet.