Features

Applications

Work Materials

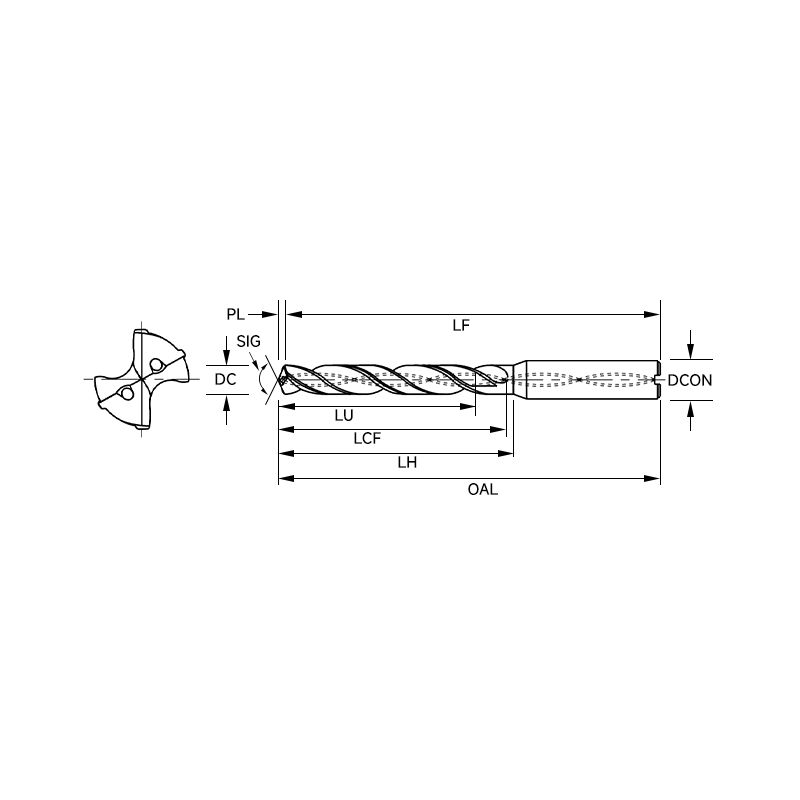

SDF-M Series General Purpose Internal Cooling Carbide Drill for Stainless Steel with DP Coating

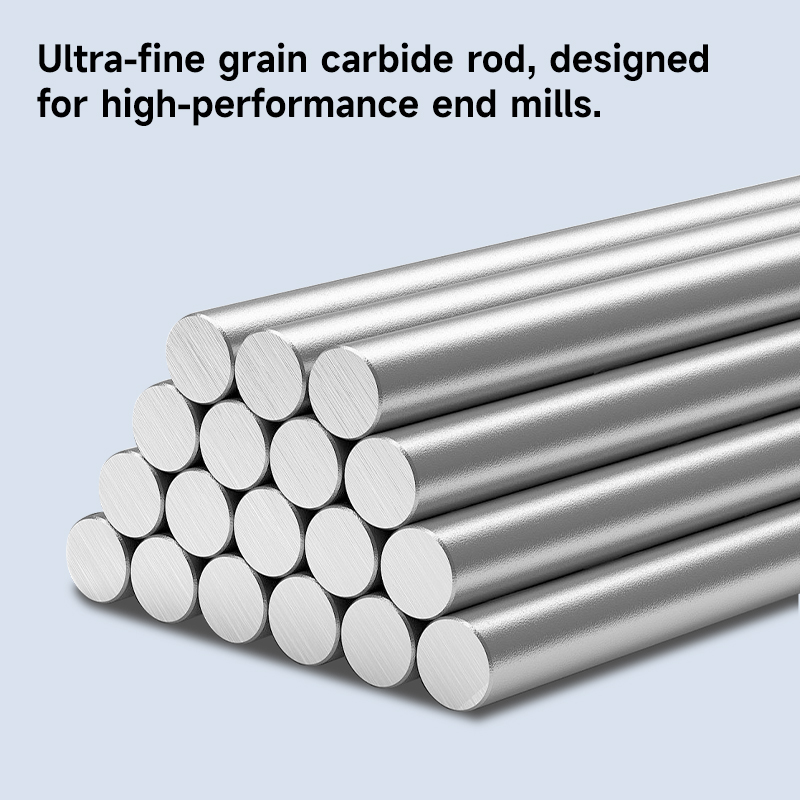

1. Product Design and Material Selection

The SDF-M series general purpose internal cooling carbide drill is specifically designed for machining various types of stainless steel, including austenitic, super-austenitic, ferritic, and duplex stainless steels. The drill is manufactured from high-quality micro-grain tungsten carbide, which offers high hardness, wear resistance, and the ability to withstand high temperatures without losing its cutting performance. Additionally, the drill features a DP (Diamond Performance) high-performance coating to enhance corrosion resistance and durability, ensuring superior performance during extended use.

2. Internal Cooling System

Equipped with an advanced internal cooling system, the SDF-M series delivers coolant directly to the cutting zone via internal channels. This design effectively reduces cutting temperatures, minimizes thermal deformation, extends tool life, and ensures excellent surface finish and machining accuracy. The internal cooling system also significantly improves chip evacuation efficiency, reducing issues such as chip clogging or overheating, thereby enhancing overall machining quality and reliability.

3. Optimized Flute Design

The flute geometry of the drill is meticulously engineered to optimize chip evacuation. The unique flute design facilitates smooth chip removal, prevents chip buildup, and avoids overheating and tool wear. This design not only increases drilling speed and quality but also enhances the stability and reliability of the machining process, especially suitable for prolonged continuous operations.

4. DP High-Performance Coating

The DP coating is specifically designed for high-load and challenging machining tasks. It provides exceptional resistance to high temperatures and wear, significantly reduces friction and wear rates, and dramatically increases the service life and machining efficiency of the drill. The DP coating maintains stable cutting temperatures during high-speed operations, ensuring efficient processing performance.

5. Centering Ability and Precision

The SDF-M series drills exhibit outstanding centering capability with tolerances reaching IT8-9, ensuring precise hole positioning and meeting high-precision machining requirements. This high-precision centering ability helps reduce deflection and vibration, guaranteeing straightness and roundness in drilled holes, thus enhancing overall machining quality. Accurate drilling is crucial for subsequent processes like threading or assembly.

6. Deep Hole Drilling Capability

Capable of achieving drilling depths up to 8 times the diameter, the SDF-M series is ideal for deep-hole drilling applications. This feature makes the drill suitable for scenarios requiring long drill holes, such as in aerospace, automotive manufacturing, and other precision engineering fields. The deep-hole drilling capability broadens the application range and provides reliable solutions for varying drilling depth requirements.

7. Comprehensive Specifications and Wide Application Range

The SDF-M series offers a comprehensive range of specifications, with diameters ranging from D3 to D20 mm, catering to diverse drilling needs. Whether for small-diameter precision drilling or large-diameter deep-hole drilling, this series provides stable and reliable solutions, adapting to various industrial applications. The drill is widely used in industries such as mechanical manufacturing, mold making, shipbuilding, petrochemicals, and more, meeting demands for efficient and precise machining.

8. Practical Application Cases

- Aerospace Industry: In aerospace manufacturing, the SDF-M series drills are used to machine high-strength stainless steel components like aircraft structural parts and engine components. The drill’s superior heat and wear resistance ensure high-quality machining results, while the internal cooling system effectively controls machining temperature, minimizing thermal deformation.

- Automotive Manufacturing: On automotive production lines, the SDF-M series drills are utilized for machining stainless steel materials in vehicle frames and chassis components. The high precision and stability of the drills ensure tight component fit, enhancing vehicle safety and reliability.

- Petrochemical Industry: In petrochemical equipment manufacturing, the SDF-M series drills are employed to machine corrosion-resistant stainless steel pipes and valves. The drills’ robust anti-corrosion properties and deep-hole drilling capabilities ensure long-term stable operation of equipment, reducing maintenance costs.

9. Summary

The SDF-M series general purpose internal cooling carbide drill combines high-quality material, advanced internal cooling systems, optimized flute design, and high-performance DP coating, making it an ideal tool for stainless steel machining. It excels in processing a wide range of stainless steel types and provides stable machining performance on complex workpieces, ensuring machining quality and efficiency. Whether for batch production or complex part machining, the SDF-M series offers reliable and efficient solutions, essential for modern manufacturing.

Reviews

There are no reviews yet.