Features

Applications

Work Materials

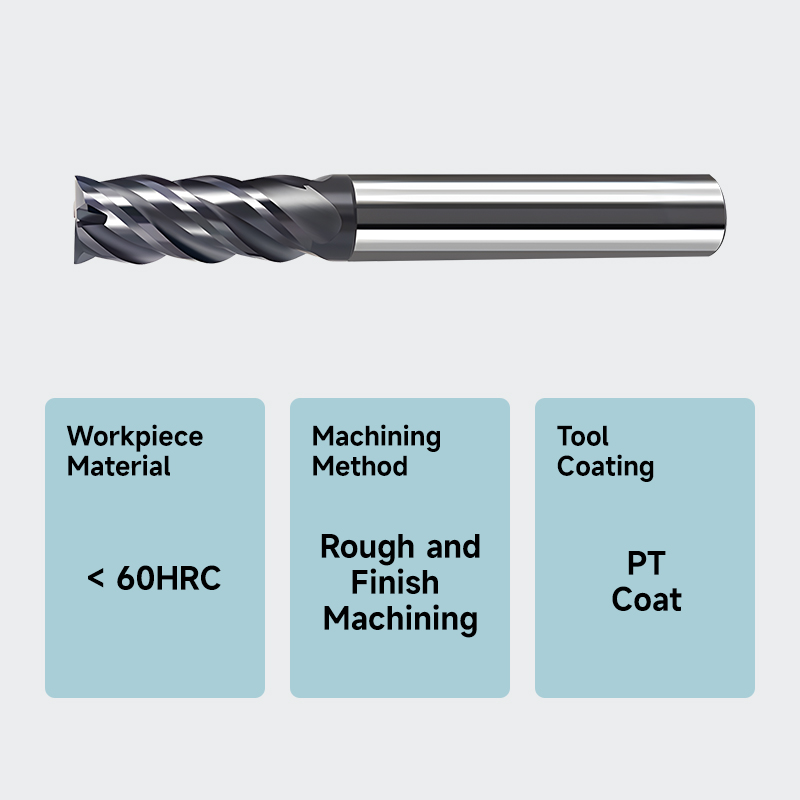

SDF-N Series 4-Flute Solid Carbide End Mill for Superalloys and Titanium Alloys

Functions

- High Metal Removal Rates:Ensures rapid and efficient material removal, optimizing productivity.

- Smooth Chip Evacuation:Smooth chip evacuation reduces the risk of chip clogging, enhancing machining efficiency.

- Excellent Wear Resistance and Anti-Adhesion Properties:Superior wear resistance and anti-adhesion properties extend tool life and improve workpiece surface finish.

- High Hardness and Toughness:High hardness and toughness make the tool suitable for machining high-hardness materials.

- Geometric Accuracy and Surface Quality:High geometric accuracy and surface quality ensure precise and high-quality machining results.

Suitable Milling Methods

- Side Milling and Contour Milling:Particularly suitable for side milling and contour milling, capable of accurately machining complex 3D surfaces and side walls, ensuring surface finish and precision.

- Slot Milling:Can also be used for slot milling, suitable for deep and narrow slots, ensuring good chip evacuation and stable cutting performance.

- High-Efficiency Milling:Ideal for high-efficiency milling, especially in the machining of complex parts requiring high precision and stability, significantly improving production efficiency.

Application Scenarios

- Aerospace Industry:Widely used in the aerospace industry for machining aircraft engine components, structural parts, and other superalloy and titanium alloy materials.

- Mold Manufacturing:Used in mold manufacturing for machining high-precision molds, ensuring surface quality and dimensional accuracy.

- Medical Device Manufacturing:Used in medical device manufacturing for machining precision medical devices, ensuring reliability and safety of the products.

- Automotive Industry:Used in the automotive industry for machining high-performance parts such as turbocharger blades and engine blocks.

- Energy Sector:Used in the energy sector for machining critical components of nuclear power, wind power, and other equipment, ensuring long-term stable operation of the equipment.

Summary

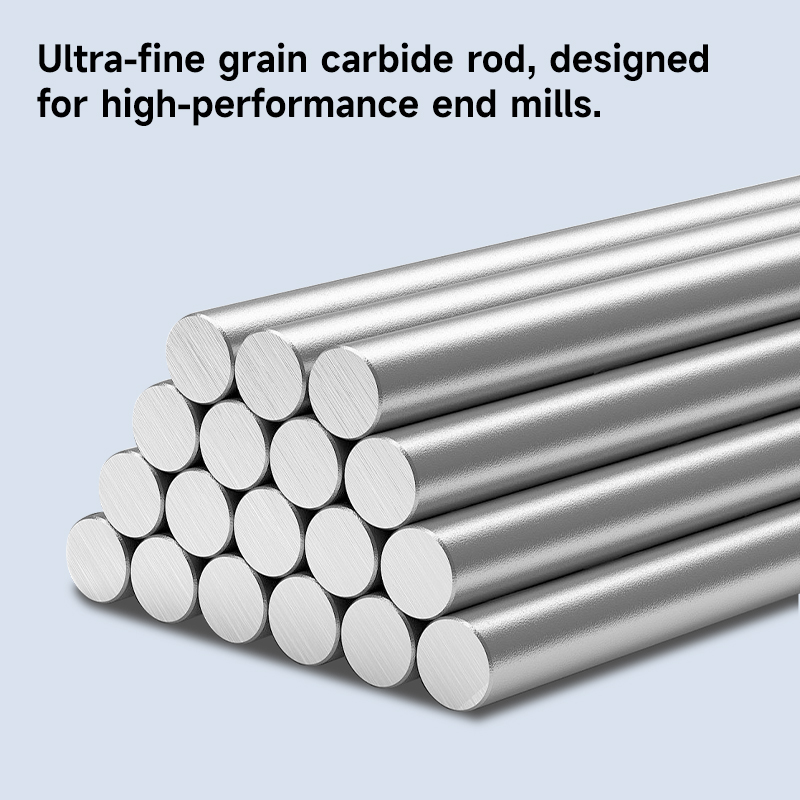

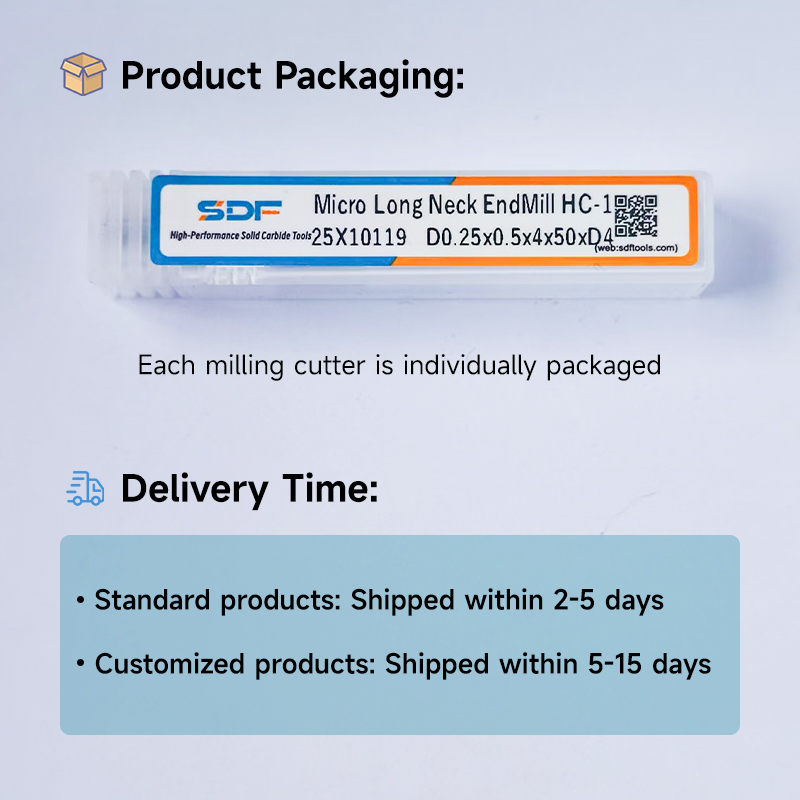

The SDF-N Series 4-Flute Solid Carbide End Mill is a high-performance tool specifically designed for machining superalloys, titanium alloys, and other difficult-to-machine materials. Its unique cutting edge geometry and advanced PT coating process ensure high metal removal rates, smooth chip evacuation, excellent wear resistance, and anti-adhesion properties. Manufactured from high-quality fine-grain micro-particle solid carbide material, the tool offers high hardness and toughness, making it suitable for machining materials with hardness up to HRC 60°. Precision grinding on advanced German WALTER five-axis grinders and inspection using German ZOLLER measuring equipment ensure geometric accuracy, surface quality, and consistent performance. This end mill is particularly suitable for side milling, contour milling, and slot milling, and is widely applied in the aerospace, mold manufacturing, medical device, automotive, and energy sectors.

Reviews

There are no reviews yet.