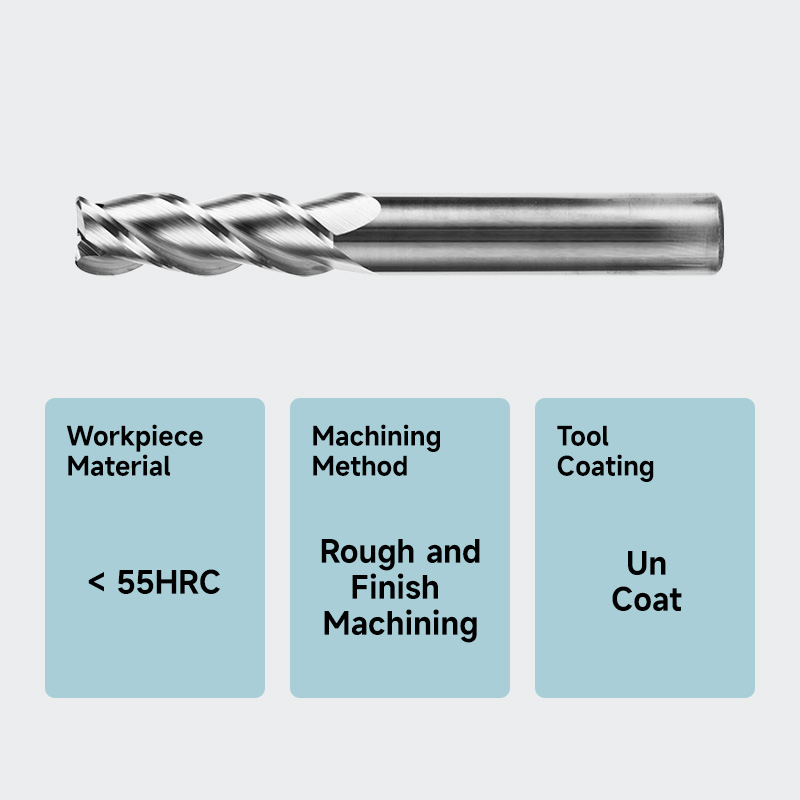

Features

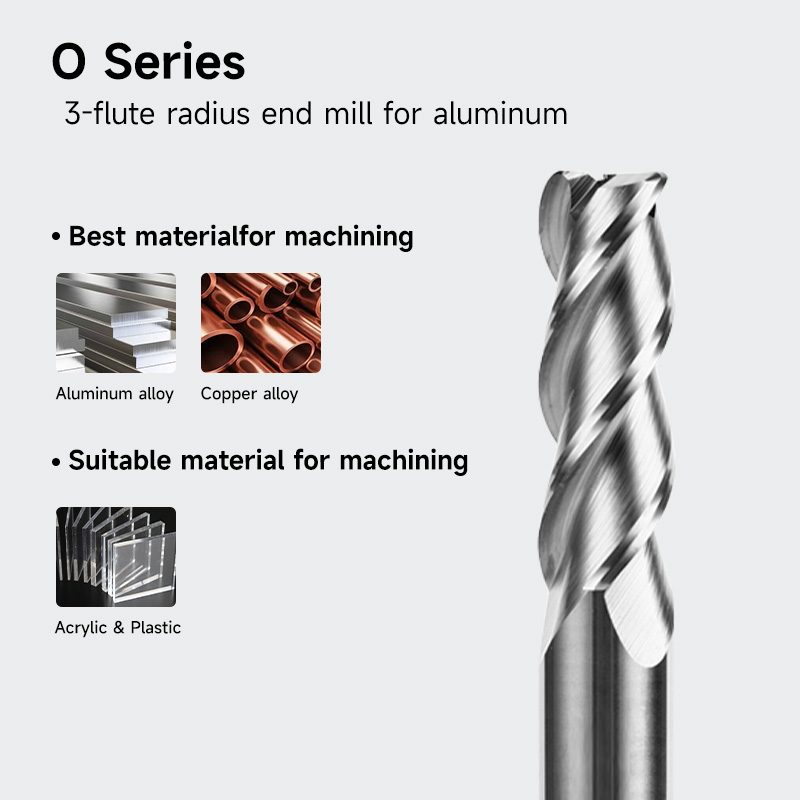

Applications

Work Materials

Features

Applications

Work Materials

SDF-O Series Solid Carbide 3-Flute Radius End Mill (Uncoated for Copper and Aluminum)

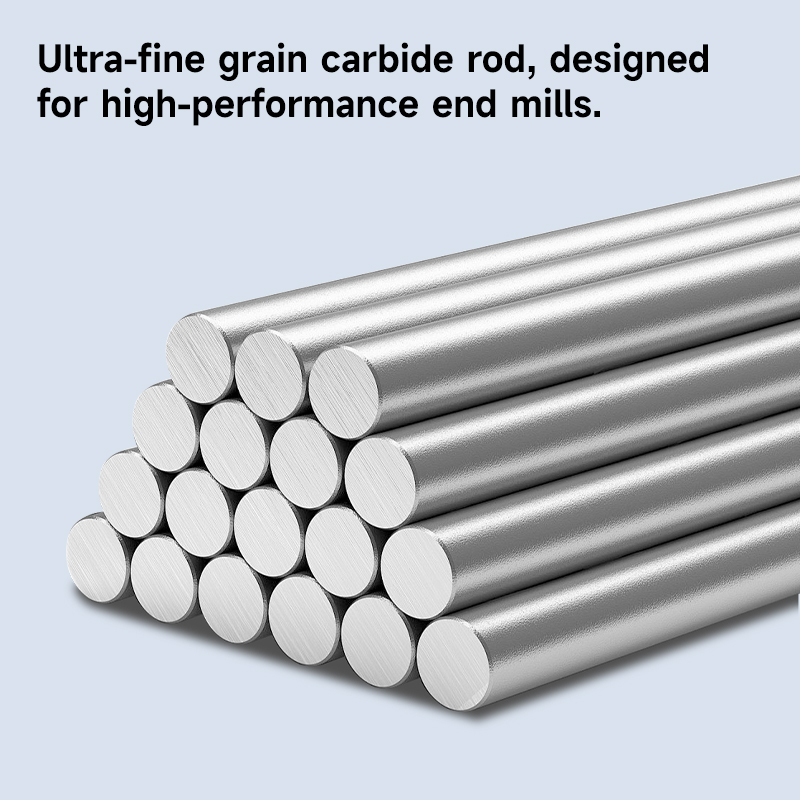

Material

- Manufactured from high-quality fine-grain micro-particle solid carbide material, ensuring high hardness and toughness. This material selection not only guarantees the durability of the tool but also enhances its stability under high-speed cutting conditions.

Design

- Unique 3-Flute Radius Design: The 3-flute radius design ensures high metal removal rates and smooth chip evacuation, specifically designed for machining soft materials such as aluminum and copper. The radius flute design reduces cutting forces and vibrations while maintaining cutting efficiency, resulting in improved surface quality.

- Uncoated Design: Specifically designed for soft material processing, the uncoated design avoids additional friction and heat effects that coatings might introduce, further extending the tool’s life and improving machining efficiency.

Functions

- High Metal Removal Rates: The 3-flute radius design enables the tool to achieve high metal removal rates during machining, particularly suitable for rapid processing of aluminum, copper, and other soft materials.

- Smooth Chip Evacuation: The optimized design ensures smooth chip evacuation, reducing the risk of chip clogging and improving both machining efficiency and tool life.

- Low Cutting Forces and Vibration: The 3-flute radius design effectively reduces cutting forces and vibrations during the machining process, ensuring a smooth and precise surface finish and dimensional accuracy.

- High Hardness and Toughness: High-quality fine-grain micro-particle solid carbide material ensures the tool has high hardness and toughness, capable of machining materials with hardness up to HRC 45°, suitable for various machining environments.

- Geometric Accuracy and Surface Quality: Precision ground on advanced German WALTER five-axis grinders, ensuring geometric accuracy and surface quality, guaranteeing consistent performance and tight tolerances.

Applications

- Aluminum and Copper Alloy Machining: Specifically designed for machining soft materials like aluminum and copper, widely used in industries such as electronics, automotive, and mold manufacturing.

- High-Precision Part Machining: Suitable for machining high-precision parts, such as electronic components, precision molds, and small mechanical parts.

- Complex Contour Machining: The 3-flute radius design and low cutting force characteristics make it ideal for machining complex contours and fine structures, ensuring dimensional accuracy and surface finish.

- Thin-Wall and Complex Components: The radius flute design reduces cutting forces and vibrations, making it particularly suitable for machining thin-wall and complex components, ensuring dimensional accuracy and surface finish.

Reviews

There are no reviews yet.