Features

Applications

Work Materials

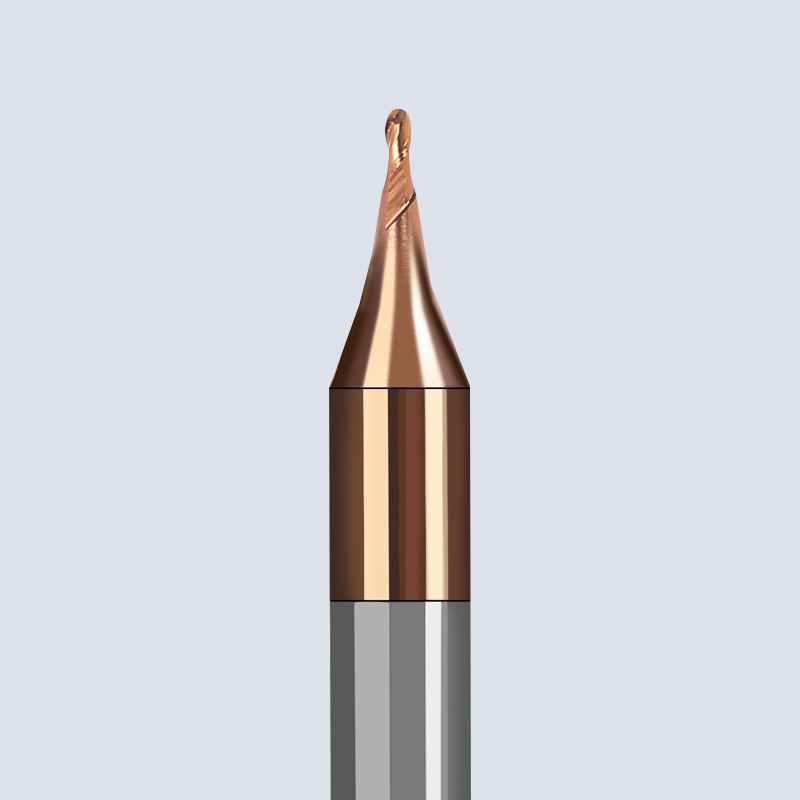

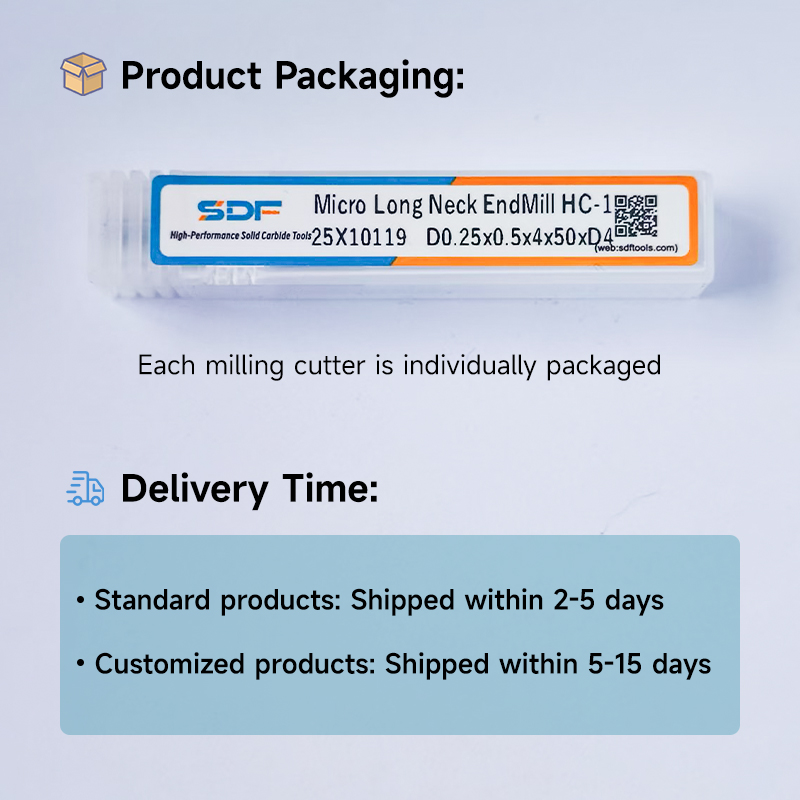

SDF-S Series Solid Carbide Micro-Diameter 2-Flute Ball Nose End Mill

Product Design

- Special Cutting Edge Geometry

- Special Cutting Edge Geometry : Features optimized cutting edge geometry to ensure high metal removal rates and efficient chip evacuation. This design is particularly suitable for high-precision and high-performance machining.

- Optimized for High Efficiency : Precise geometric design reduces cutting forces and increases cutting speeds, achieving efficient machining.

- Large Chip Clearance Design

- Large Chip Clearance Design : Designed with large chip clearance to ensure smooth chip evacuation, preventing chip clogging and extending tool life.

- Enhanced Chip Evacuation : Improves chip evacuation, reducing heat generation during cutting and further enhancing machining efficiency and surface quality.

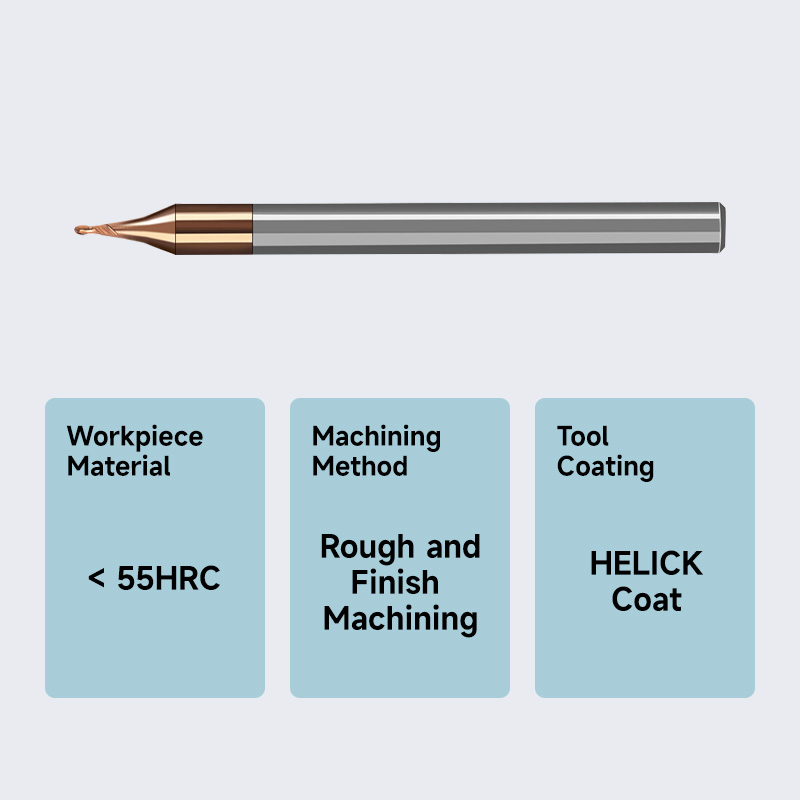

- Advanced HELICK Coating

- Advanced HELICK Coating : Coated with an advanced HELICK coating to significantly enhance wear resistance and reduce friction.

- Improved Wear Resistance : The HELICK coating effectively resists wear, extending tool life.

- Reduced Friction : Reduces friction during cutting, minimizing heat generation and improving surface finish.

- High-Quality Solid Carbide Construction

- High-Quality Solid Carbide Construction : Manufactured from high-quality solid carbide to ensure high hardness and toughness.

- Capable of Machining Hard Materials : Capable of machining materials with hardness up to HRC 55, suitable for precision machining of hard materials.

- State-of-the-Art Grinding Technology

- State-of-the-Art Grinding Technology : Manufactured using the latest grinding technology to ensure precise geometry and surface quality.

- Consistent Performance and Tight Tolerances : Ensures consistent performance and strict tolerances, meeting the requirements of high-precision machining.

Function

- Ultra-High Metal Removal Rates

- Ultra-High Metal Removal Rates : Achieves extremely high metal removal rates through special cutting edge design and large chip clearance design, significantly improving machining efficiency.

- Excellent Surface Finish

- Excellent Surface Finish : The combination of HELICK coating and advanced grinding technology ensures a high-quality surface finish, reducing the need for additional finishing processes.

- Extended Tool Life and High Reliability

- Extended Tool Life : The HELICK coating and high-quality carbide material ensure long tool life and high reliability, reducing replacement frequency and maintenance costs.

- Versatile Applications

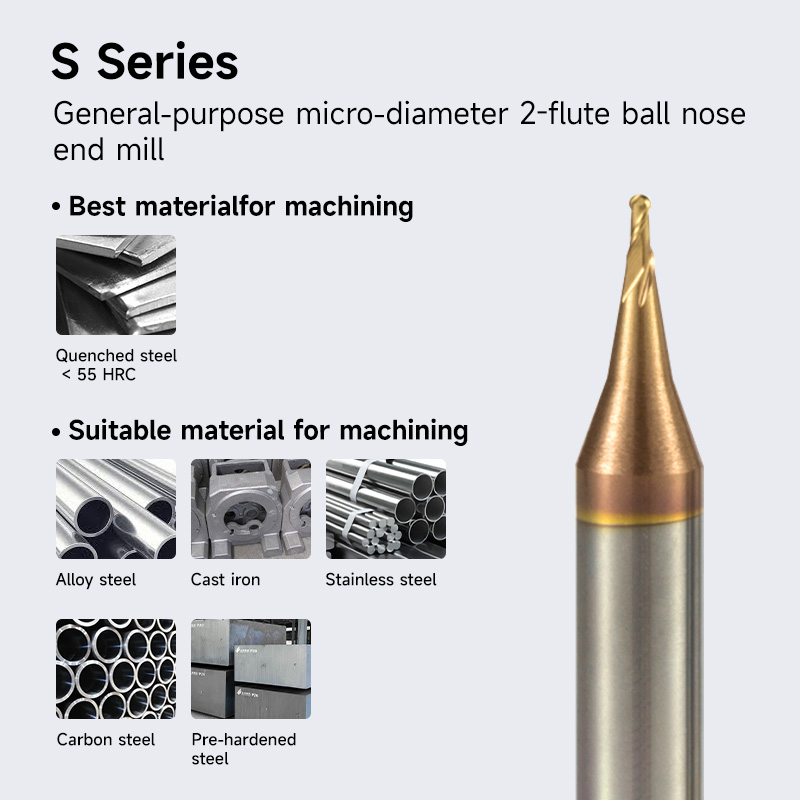

- Versatile Applications : Suitable for machining a variety of materials, including copper and aluminum alloys, stainless steel, and mold steel, meeting the needs of different machining applications.

Applicable Conditions and Materials

- Hard Materials

- Hard Materials : Suitable for machining materials with hardness up to HRC 55, such as quenched steel and mold steel.

- High Hardness Materials : Achieves efficient cutting and excellent surface quality on high-hardness materials.

- Soft Materials

- Soft Materials : Also suitable for machining soft materials, such as copper and aluminum alloys, brass, etc.

- Non-Ferrous Metals : Performs well on non-ferrous metals, providing good cutting performance and surface finish.

- Complex Surface Machining

- Complex Surface Machining : Suitable for machining complex surfaces and 3D contours, such as molds and aerospace components.

- 3D Contouring : Achieves high-precision 3D contour machining, ensuring complex geometric shapes.

Application Fields

- Mold and Die Making

- Mold and Die Making : Suitable for precision machining of molds and dies, capable of achieving complex surfaces and detailed features, ensuring high precision and long life of the molds.

- Aerospace Industry

- Aerospace Industry : Suitable for high-performance machining in the aerospace industry, capable of machining high-hardness and high-precision parts, meeting stringent performance requirements.

- Precision Engineering

- Precision Engineering : Suitable for high-precision machining in fields such as precision machinery and electronic devices, ensuring high-quality and reliable products.

- Automotive Manufacturing

- Automotive Manufacturing : Suitable for machining automotive components, achieving efficient and high-precision machining, improving production efficiency and product quality.

- Medical Devices

- Medical Devices : Suitable for precision machining of medical devices, ensuring high precision and reliability of medical equipment.

Summary

The SDF-S Series Solid Carbide Micro-Diameter 2-Flute Ball Nose End Mill with HELICK Coating, HRC 55 is a high-performance precision machining tool. Through special design and advanced coating technology, it achieves high metal removal rates, excellent surface finish , and long life. Suitable for a wide range of high-precision machining applications, it is an ideal choice for modern manufacturing.

Reviews

There are no reviews yet.