Features

Applications

Work Materials

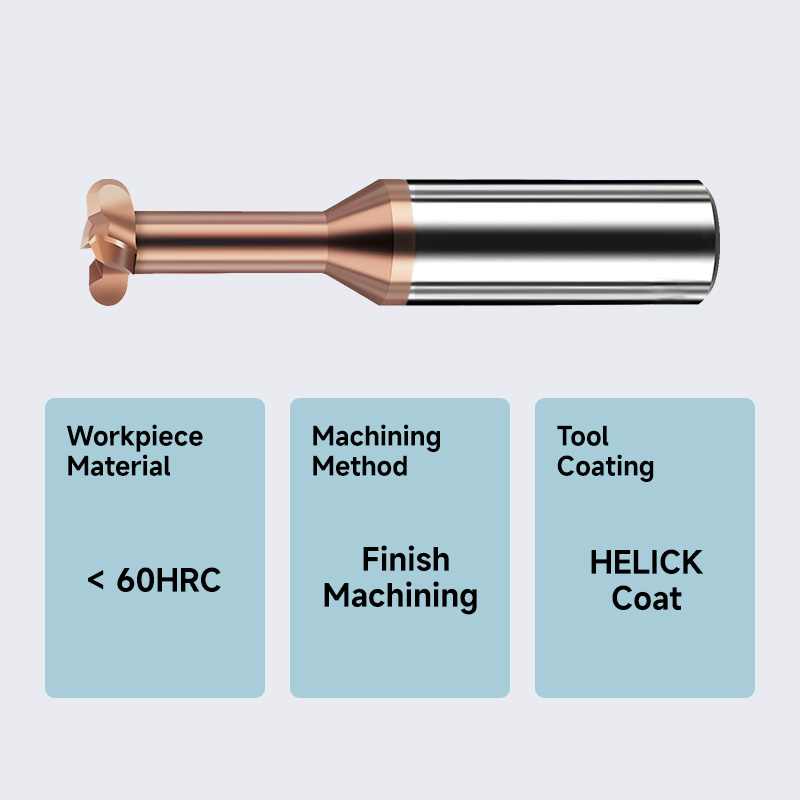

SDF-T Series Solid Carbide 4-Flute Universal T-Slot Ball Nose End Mill

Product Overview

The SDF-T Series Solid Carbide 4-Flute Universal T-Slot Ball Nose End Mill is a high-performance tool specifically designed for efficient and precise machining of complex surfaces and T-slots. This series of tools is made from high-quality fine-grain solid carbide material, ensuring high hardness and toughness, capable of machining materials with hardness up to HRC 60°. The unique cutting edge design and optimized helix angle, combined with a special T-slot design, make the tool excel in various machining applications. Additionally, the tool features an advanced HELICK coating, which significantly enhances wear resistance and anti-adhesion properties, extending tool life and improving surface finish.

Product Features

- High Hardness and Toughness:

- Made from high-quality fine-grain solid carbide material, ensuring the tool has high hardness and toughness, capable of machining materials with hardness up to HRC 60°.

- Suitable for a wide range of materials, including high-strength steel, stainless steel, and aluminum alloys.

- Unique Cutting Edge Design:

- Unique 4-flute cutting edge design increases cutting efficiency, reduces machining time, and improves surface finish.

- Optimized cutting edge geometry ensures high metal removal rates and excellent cutting performance.

- Optimized Helix Angle Design:

- Optimized helix angle design balances cutting forces and chip evacuation, reducing vibration and cutting heat.

- Enhances machining stability and extends tool life.

- Special T-Slot Design:

- Special T-slot design ensures precise contour matching and depth control during machining, making it particularly suitable for T-slots and similar structures.

- Accurate contour matching and depth control reduce machining errors and improve efficiency.

- Smooth Chip Evacuation Grooves:

- Designed with smooth chip evacuation grooves to ensure chips are smoothly expelled, reducing chip clogging and improving machining efficiency and tool life.

- Optimized chip evacuation grooves help maintain tool cleanliness and efficient operation.

- Advanced HELICK Coating:

- Surface treated with advanced HELICK coating, significantly enhancing wear resistance and anti-adhesion properties.

- Extends tool life, improves surface finish, reduces heat generation during cutting, and increases cutting efficiency.

- High Precision and Surface Quality:

- Precision ground on advanced German WALTER five-axis grinders, ensuring geometric accuracy and surface quality.

- Guarantees consistent performance and strict tolerances, meeting the requirements of high-precision machining.

Main Applications

- Mold Machining:

- Widely used in mold manufacturing, especially for complex surfaces and high-precision molds, such as injection molds and die-casting molds.

- Ensures high precision and good surface quality, meeting the demands of high-end manufacturing.

- Aerospace Components Machining:

- Suitable for machining aerospace components, such as aircraft wing ribs and engine blades, which typically require high precision and complex geometries.

- High hardness and toughness of the material ensure stability and reliability under high load and high-speed cutting conditions.

- Automotive Components Machining:

- Used for machining automotive components, such as intake manifolds and oil pans, which require high precision and good surface quality.

- Optimized cutting edge design and smooth chip evacuation grooves improve machining efficiency and tool life.

- T-Slot Machining:

- Specifically designed for machining T-slots, ensuring precise contour matching and depth control, suitable for industries such as mechanical machining, aerospace, and automotive manufacturing.

- Special T-slot design and optimized helix angle ensure stability and reliability during machining.

- Precision Parts Machining:

- Suitable for machining precision parts, such as mold inserts and precision mechanical components, ensuring high precision and stability.

- High precision and good surface quality meet the requirements of precision machining.

Reviews

There are no reviews yet.