Features

Applications

Work Materials

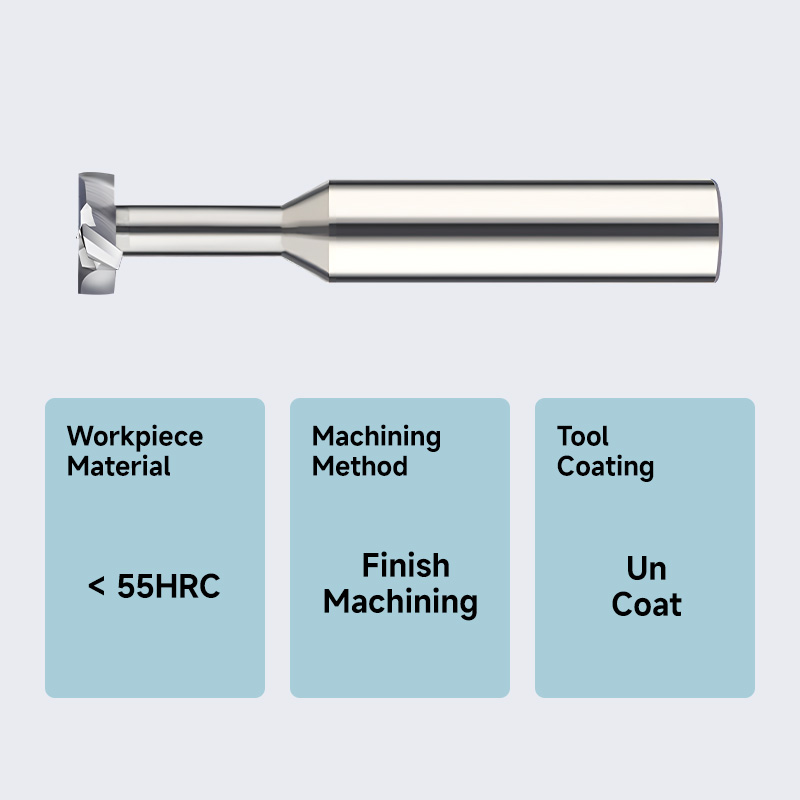

SDF-T Series Solid Carbide T-Slot Milling Cutter (Aluminum and Copper Alloys Specific, Uncoated)

Product Overview

The SDF-T Series Solid Carbide T-Slot Milling Cutter (Aluminum and Copper Alloys Specific, Uncoated) is a high-performance tool specifically designed for efficient and precise machining of soft materials like aluminum and copper alloys. This series of tools features a unique T-slot cutting edge design that ensures high metal removal rates and smooth chip evacuation. Manufactured from high-quality fine-grain solid carbide material, the tool ensures high hardness and toughness, capable of machining materials with hardness up to HRC 45°. Precision grinding on advanced German WALTER five-axis grinders and inspection using German ZOLLER measuring equipment ensure the tool’s geometric accuracy, surface quality, and consistent performance.

Product Features

- Unique T-Slot Cutting Edge Design:

- A unique T-slot cutting edge design ensures high metal removal rates and smooth chip evacuation.

- Specifically designed for machining soft materials like aluminum and copper alloys, reducing cutting forces and improving machining efficiency and surface quality.

- High-Quality Fine-Grain Solid Carbide Material:

- Manufactured from high-quality fine-grain solid carbide material, ensuring the tool has high hardness and toughness.

- Capable of machining materials with hardness up to HRC 45°, suitable for a variety of alloy materials.

- Precision Ground on Advanced German WALTER Five-Axis Grinders:

- Precision ground on advanced German WALTER five-axis grinders, ensuring geometric accuracy and surface quality.

- Guarantees consistent performance and strict tolerances, meeting the requirements of high-precision machining.

- Inspected Using German ZOLLER Measuring Equipment:

- Inspected using German ZOLLER measuring equipment, with each tool individually inspected, ensuring high and stable tool quality.

- Strict quality control ensures the reliability and consistency of the tool.

Functions

- High Metal Removal Rate: The unique T-slot cutting edge design ensures high metal removal rates, reducing machining time.

- Smooth Chip Evacuation: Optimized cutting edge design and uncoated treatment ensure smooth chip evacuation, preventing chip clogging and improving machining efficiency.

- High-Precision Machining: Advanced manufacturing and inspection processes ensure the tool’s high precision, suitable for applications requiring high accuracy.

- Long Life and High Toughness: High-quality fine-grain solid carbide material and uncoated design ensure the tool’s long life and high toughness, reducing replacement frequency and maintenance costs.

Application Scenarios

- Metal Machining:

- Widely used in industries such as mechanical machining, aerospace, and automotive manufacturing, suitable for T-slot milling of aluminum, copper, and other alloy soft materials.

- Ensures high precision and good surface quality, meeting the demands of high-end manufacturing.

- Precision Part Machining:

- Suitable for T-slot milling of precision parts, such as molds and precision mechanical components.

- High precision ensures stability and reliability during machining.

- Efficient Production:

- Optimized cutting edge design and uncoated treatment enable the tool to achieve efficient machining while maintaining high precision and good surface quality.

- Increases production efficiency, reduces production costs, and is suitable for high-volume production environments.

- Complex T-Slot Machining:

- Suitable for T-slot milling of complex parts, such as multi-angle and multi-position T-slots.

- Optimized design and high-quality material ensure stability and reliability during machining.

Reviews

There are no reviews yet.