Features

Applications

Work Materials

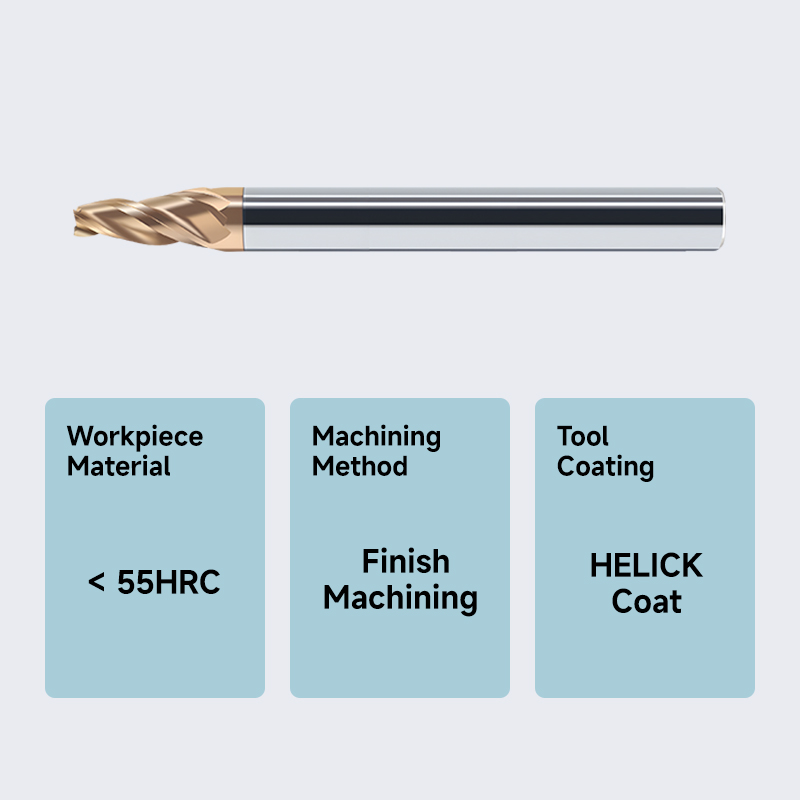

SDF-W Series Solid Carbide 3-Flute Tapered End Mill, HELICK Coated, HRC 55°

Product Features

- High Hardness and Toughness:

- Made from high-quality fine-grain solid carbide material, ensuring the tool has high hardness and toughness, suitable for materials with hardness up to HRC 55°. This material maintains excellent performance in high-strength and high-hardness machining environments.

- Unique 3-Flute Cutting Edge Design:

- Unique 3-flute cutting edge design increases cutting efficiency, reduces machining time, and improves surface finish. The optimized cutting edge geometry ensures high metal removal rates and excellent cutting performance, particularly suitable for complex surfaces and high-precision machining.

- Precision Tapered Design:

- Precision tapered design ensures high accuracy and stability, making it suitable for efficient taper machining of various materials. This design achieves precise contour matching, reducing machining errors and improving efficiency.

- HELICK Coating:

- Coated with HELICK, enhancing the tool’s wear resistance and corrosion resistance, further improving tool life and machining efficiency. HELICK coating effectively reduces friction during cutting, lowers cutting temperature, and extends tool life.

- High Precision and Surface Quality:

- Precision ground on advanced German WALTER five-axis grinders, ensuring geometric accuracy and surface quality. Strict tolerances and consistent performance meet the requirements of high-precision machining, suitable for applications with high precision demands.

Machining Methods

- Efficient Metal Removal:

- Unique 3-flute cutting edge design and optimized helix angle ensure high metal removal rates, reducing machining time.

- Smooth Chip Evacuation:

- Smooth chip evacuation grooves ensure chips are smoothly expelled, reducing chip clogging and improving machining efficiency.

- High Precision Machining:

- Advanced manufacturing and inspection processes ensure high precision, suitable for high-precision machining applications.

- Long Life and High Toughness:

- High-quality fine-grain solid carbide material and HELICK coating ensure long tool life and high toughness, reducing replacement frequency and maintenance costs.

Applications

- High-Strength Material Machining:

- Particularly suitable for high-strength materials with hardness up to HRC 55°, such as mold steel and stainless steel. The high hardness and toughness of the material ensure excellent performance in these materials.

- Taper Machining:

- Specifically designed for machining tapered slots and tapered holes, ensuring precise contour and depth control. The precision tapered design and optimized helix angle ensure stability and reliability during machining.

- Precision Parts Machining:

- Suitable for machining precision parts, such as mold inserts and precision mechanical components, ensuring high precision and stability. High precision and good surface quality meet the requirements of precision machining.

Reviews

There are no reviews yet.