Subtitle: Exploring the Role of Industrial Microscopes in Enhancing the Quality and Performance of CNC Tools

Abstract

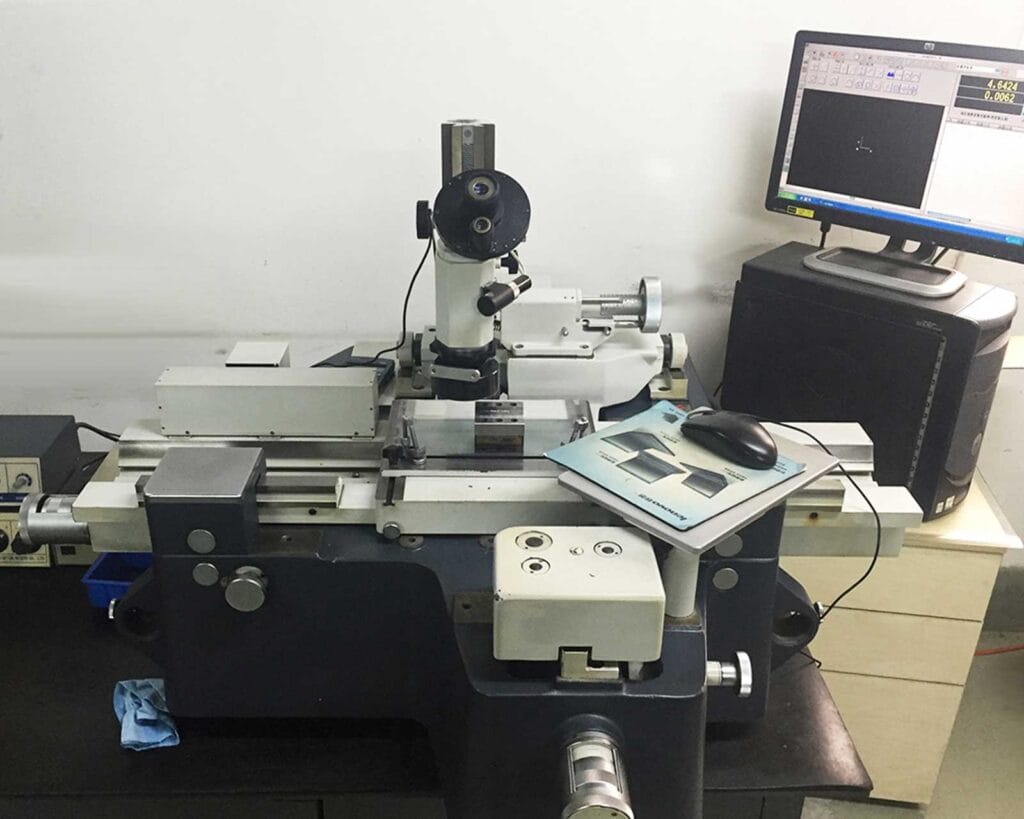

In modern manufacturing, the precision of CNC (Computer Numerical Control) tools directly affects the quality of the final product and production efficiency. To ensure these tools are in optimal condition, regular detailed inspections using industrial microscopes become crucial. This article will explore four aspects of why CNC tools need to be inspected under industrial microscopes: ensuring geometric accuracy, detecting surface defects, monitoring wear conditions, and optimizing service life. It emphasizes how this method can significantly improve product quality and reduce costs.

1. Ensuring Geometric Accuracy

- The design requirements for CNC tools are extremely high, and even slight deviations can lead to the failure of the entire machining process.

- Industrial microscopes help technicians accurately measure various dimensions of the tool, such as cutting edge angles, to ensure they meet the design specifications.

- Regular inspections help in promptly identifying any issues that may affect machining accuracy and taking corrective actions.

2. Detecting Surface Defects

- Flaws on the tool’s surface, such as cracks, pits, or other imperfections, can greatly reduce its lifespan and machining effectiveness.

- Through high-magnification observation, industrial microscopes can effectively identify small defects that are hard to detect with the naked eye.

- Addressing these issues in a timely manner not only extends the tool’s life but also prevents an increase in scrap rates due to quality problems.

3. Monitoring Wear Conditions

- Over time, all cutting tools experience varying degrees of wear.

- By closely observing the tool edges with an industrial microscope, early signs of wear can be detected sooner.

- This early warning system allows companies to schedule replacements or repairs without disrupting production schedules.

4. Optimizing Service Life

- Properly assessing the actual condition of each tool is essential for planning maintenance cycles effectively.

- Combining the information provided by industrial microscopes, a more scientific and reasonable maintenance plan can be developed.

- This approach not only maximizes resource utilization but also helps in reducing unnecessary expenses.

Conclusion

In summary, regularly inspecting CNC tools under industrial microscopes is a critical step in ensuring smooth manufacturing processes. It not only helps businesses maintain high standards of product quality but also effectively controls cost expenditures. Therefore, whether for large manufacturers or small workshops, this practice should be given due importance and considered an indispensable part of daily operations.

sdftoolscnc tools