Introduction: The Persistent Problem of 6061 Aluminum Machining

6061 aluminum alloy, the most widely used heat-treatable alloy in modern industry, has become the material of choice for automotive, aerospace, and marine applications due to its excellent formability, weldability, and machinability. However, these very properties create significant aluminum machining challenges, particularly with chip control.

During precision machining, 6061 aluminum’s low density and high ductility generate continuous ribbon chips that silently undermine productivity:

- Tool life reduction up to 70% due to chip entanglement

- 40%+ decrease in equipment utilization from frequent chip-clearing stops

- Surface scratches increasing rejection rates

- Conservative parameters limiting efficiency to just 60% of potential

Most manufacturers face an impossible choice: tolerate inefficient production or bear exorbitant tool replacement costs.

Industry Case Study: Transformative Results in Automotive Valve Body Production

3.1 The Production Bottleneck

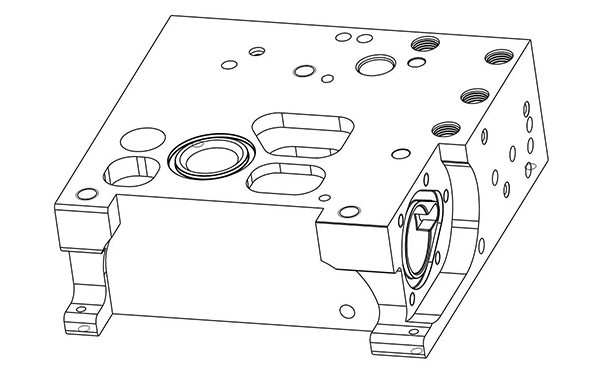

A global automotive components manufacturer struggled with a critical production constraint – chip control issues in Φ23.81 hole machining for brake system valve bodies.

“We tried every available solution,” confessed their Production Director, “from parameter adjustments to frequent tool changes and even expensive new equipment, but nothing provided a fundamental solution.”

3.2 SDFTools’ Engineering Breakthrough

Our analysis revealed key aluminum machining challenges:

- Conventional tool geometry ignored 6061’s unique properties

- Oversimplified chip breaker designs failed to control chip flow

- Insufficient tool complexity necessitated multiple operations

- Suboptimal coolant strategies for aluminum

These insights guided our revolutionary solution development.

Part Specifications & Customer Requirements

- Component: Brake system valve body

- Material: 6061 aluminum

- Machine: Horizontal machining center

- Cooling: Internal emulsion coolant

- Features: Φ21/Φ23.81 holes

- Requirement: Solve continuous chip issue in Φ23.81 machining

The Core Machining Challenges

- 6061 aluminum’s exceptional ductility creates persistent ribbon chips that dangerously wrap around tools and holders

- Step drilling particularly struggles with chip breaking due to small axial depths of cut and insufficient bending moments

SDFTools’ Innovative Solution

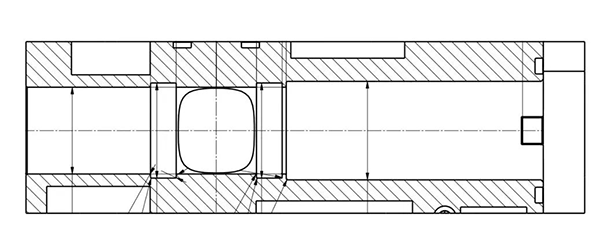

Key Design Features:

- Material-specific rake angle modifications ensure optimal chip flow into breakers

- Multi-stage chip control technology with strategically placed breakers creates segmented, curled, and broken chips

Dramatic Performance Improvements

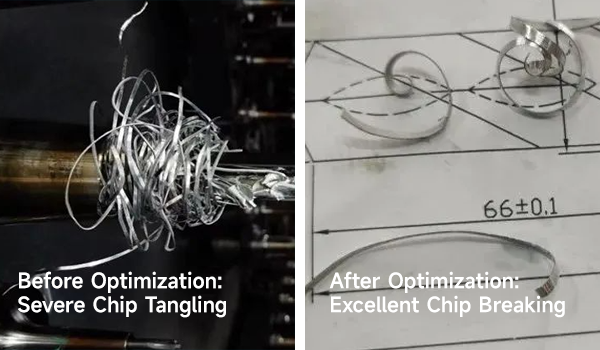

Before Optimization: Severe Chip Tangling — After Optimization: Excellent Chip Breaking

Performance Comparison:

| Metric | Conventional | SDFTools | Improvement |

|---|---|---|---|

| Tool Life | 300 pcs | 1,500 pcs | 500% |

| Efficiency | Baseline | 260% | 160% |

| Surface Finish | Ra3.2 | Ra1.6 | 50% better |

| Cost per Part | 100% | 60% | 40% saving |

| Equipment Utilization | 65% | 90% | 38% gain |

Test Parameters:

- Tool: Φ20.7/Φ23.51

- Speed: 3,500 RPM

- Feed: 1,200 mm/min

- Result: Perfect chip control with single-tool operation replacing multiple tools

Customer Testimonial: From Skepticism to Enthusiasm

“We were initially skeptical,” admitted the Technical Director, “but the first trial showed remarkable changes.”

Production Results:

- Monthly output increased from 15,000 to 39,000 units

- 58% reduction in tooling costs

- Quality rate improved from 92% to 99.7%

- Overall Equipment Effectiveness (OEE) reached 89%

- ROI achieved in just 23 days

Why Leading Manufacturers Choose SDFTools

- 20-Year Expertise: Specialized in difficult-to-machine materials

- German Precision Standards: 72 quality control steps per tool

- Complete Solutions: Holistic process optimization

- Rapid Response: Custom solutions within 48 hours

- Cost Efficiency: Maximizing value from every investment

Take Action: Transform Your Aluminum Machining Today!

Stop letting aluminum machining challenges limit your productivity! Contact SDFTools now for:

✓ Free process evaluation

✓ Custom tooling recommendations

✓ Ongoing technical support

Website: www.sdftools.com

Email: sdfgroup@sdftools.com

LinkedIn: www.linkedin.com/in/sdfcnctools

WhatsApp: +65 89420188

Choosing SDFTools means selecting more than tools – you’re gaining a trusted partner for manufacturing excellence. Let’s revolutionize aluminum machining together!