In the machining industry, carbide tools are essential core tools. With their excellent hardness , wear resistance , and heat tolerance , they have become the preferred choice for high-efficiency machining. However, with a wide variety of carbide tools available, how do you choose the right one? Today, we’ll start from the basics to give you a comprehensive understanding of carbide cutting tools .

What Are Carbide Tools?

Carbide tools are cutting tools made from composite materials — primarily hard particles (e.g., tungsten carbide, WC) and binder phase (e.g., cobalt, Co) — formed through powder metallurgy sintering. Their performance features include:

- High Hardness : Ideal for cutting high-strength materials.

- Excellent Wear Resistance : Extends tool life.

- Heat Resistance : Suitable for high-speed machining.

💡 Pro Tip : The hardness and toughness of carbide tools depend on the ratio of tungsten carbide to cobalt. Higher cobalt content improves toughness; higher tungsten carbide content increases hardness.

Carbide Composition and Performance

The main components of carbide are tungsten carbide (WC) and cobalt (Co) , and their proportion determines the tool’s performance:

- Tungsten Carbide (WC)

- Provides high hardness and wear resistance.

- The higher the WC content, the harder the tool — but also more brittle.

- Cobalt (Co)

- Acts as a binder, enhancing toughness and impact resistance.

- Higher Co content makes the tool “softer” but better suited for interrupted cuts or heavy vibration scenarios.

✨ Application Suggestions :

- High-WC tools are ideal for continuous cutting (e.g., turning steel parts).

- High-Co tools are better for interrupted cutting or difficult-to-machine materials (e.g., stainless steel, titanium alloys).

Solid Carbide vs Indexable Inserts: Which One Is Right for You?

Carbide tools mainly come in two forms: solid carbide tools and indexable insert tools . Each has its own advantages and is suitable for different machining scenarios.

1️⃣ Solid Carbide Tools

- Entirely made of carbide material.

- Advantages :

- Sharp cutting edges, ideal for precision machining .

- Low vibration, suitable for small part machining .

- Disadvantages :

- Higher cost; the entire tool must be replaced when worn.

- Applications : Drilling, milling small parts, finishing operations.

2️⃣ Indexable Insert Tools

- Carbide inserts mounted on tool bodies.

- Advantages :

- Easy replacement — only the insert needs changing.

- Lower cost, ideal for mass production .

- Disadvantages :

- Cutting edges are not as sharp as solid carbide, possibly affecting surface finish.

- Applications : Turning, roughing, large-scale production.

Common Types of Carbide Tools

Based on machining requirements, carbide tools can be categorized into the following types:

- Turning Tools

- Used for external turning, internal boring, and face machining.

- Common shapes: Square, diamond, and round inserts.

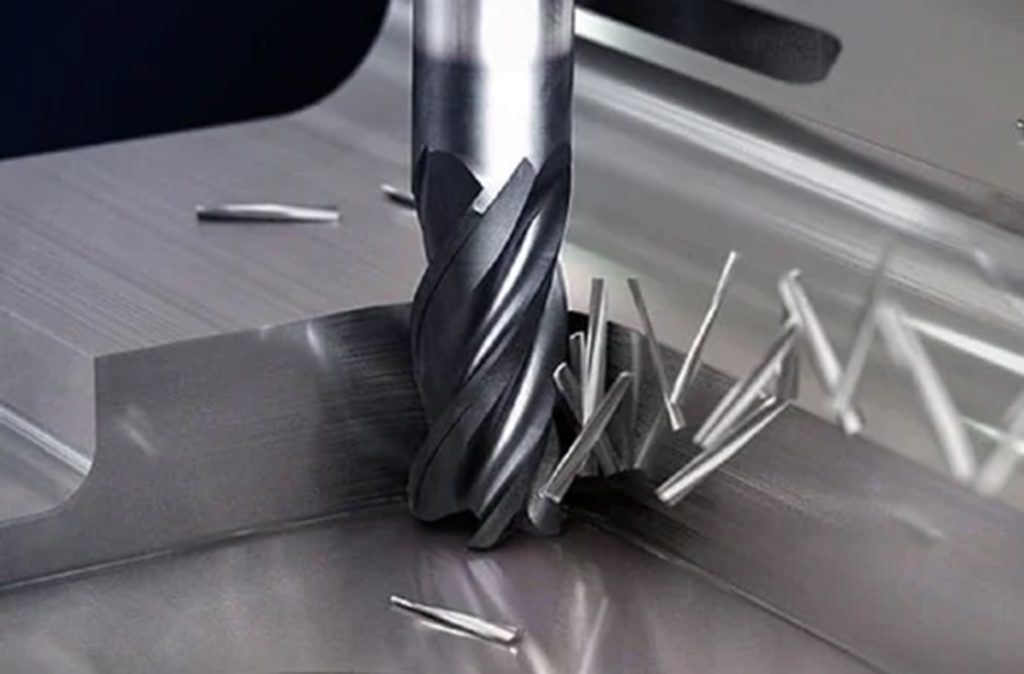

- End Mills

- For flat surfaces, profiling, and slotting.

- Common types: Flat-end mills, ball nose end mills, face mills.

- Drills

- Designed for drilling tasks such as deep holes, shallow holes, and threaded holes.

- Common types: Solid carbide drills, indexable drills.

- Boring Tools

- Used for precision boring of internal bores, improving dimensional accuracy and surface finish.

Why Are Carbide Tools So Important?

The advantages of carbide tools lie not only in their material properties but also in their ability to significantly improve machining efficiency and reduce costs:

- Boost Productivity : Supports higher cutting speeds and feed rates.

- Reduce Costs : Longer tool life reduces replacement frequency and downtime.

- Adaptability Across Materials : Capable of machining everything from general steels to tough materials like titanium alloys and high-temperature alloys .

Summary: The Basics of Choosing Carbide Tools

The key to selecting the right carbide tool lies in understanding its material composition and structural design. With this foundation, you can make better choices based on your machining needs:

- If you require high precision and sharp cutting edges , choose solid carbide tools .

- If you’re aiming for cost-effectiveness and high-volume production , go for indexable inserts .

💡 Final Question: What type of carbide tool do you use most often in your daily work? Have you encountered any challenges during use?

Feel free to share your experience in the comments below! 🚀