In the field of precision manufacturing, tolerance control capability is a key indicator of a company’s technical expertise. Recently, SDFTools successfully delivered a custom-made carbide straight flute reamer to a client in the semiconductor equipment manufacturing industry, achieving a hole diameter tolerance of ±0.002 mm (±2 microns) — a level that belongs to the realm of ultra-precision machining, far exceeding conventional industrial standards.

This project not only demonstrates SDFTools’ core technical capabilities in non-standard tool design and manufacturing, but also highlights our comprehensive strengths in equipment support, process control, inspection systems, and service responsiveness.

📌 Client Requirements: The Challenge of Ultra-Precision Machining

The client specializes in the production of high-end semiconductor equipment components, one of which required precision hole finishing for positioning, with the following specifications:

- Material Type: Stainless steel / Titanium alloy

- Hole Diameter Specifications: D1.78mm, D0.64mm, D1.307mm

- Tolerance Requirement: ±0.002 mm (only 4 microns between upper and lower limits)

- Surface Roughness: Ra ≤ 0.4 μm

- Application Scenario: Key connection holes in wafer alignment systems

The client’s previously used reamers had the following issues:

- Large hole diameter variation, often exceeding ±0.005 mm;

- Unstable surface quality requiring additional polishing;

- Short tool life, frequent replacements affecting production efficiency.

Faced with such strict requirements, we quickly launched the “±0.002 mm-level” custom project, aiming to develop a reamer with ultra-high precision, long life, and stable performance.

🔧 Our Solution: Full-Process Precision Control from Design to Inspection

✅ High-Rigidity Structural Design

- Made from solid carbide material to ensure substrate strength and thermal stability;

- Straight flute design reduces axial vibration during cutting, enhancing stability;

- Edge treated with 0.01mm honing for a balance between sharpness and wear resistance.

✅ Nanometer-Level Manufacturing Accuracy

- Utilized Swiss-imported 5-axis CNC grinding machines (precision up to ±0.0005 mm) to ensure dimensional consistency across all tools;

- Key dimensional controls include:

- Outer diameter: ±0.002 mm

- Shank diameter: h6 (±0.003 mm)

- Surface treatment: Mirror polishing (Ra ≤ 0.2 μm), reducing friction resistance.

✅ High-Precision Coating & Edge Treatment

- Applied TiAlN nano-coating (thickness 3.5 μm) to enhance wear resistance;

- Edges micro-polished and chamfered (C0.2×45°) to further improve cutting stability and chip removal efficiency.

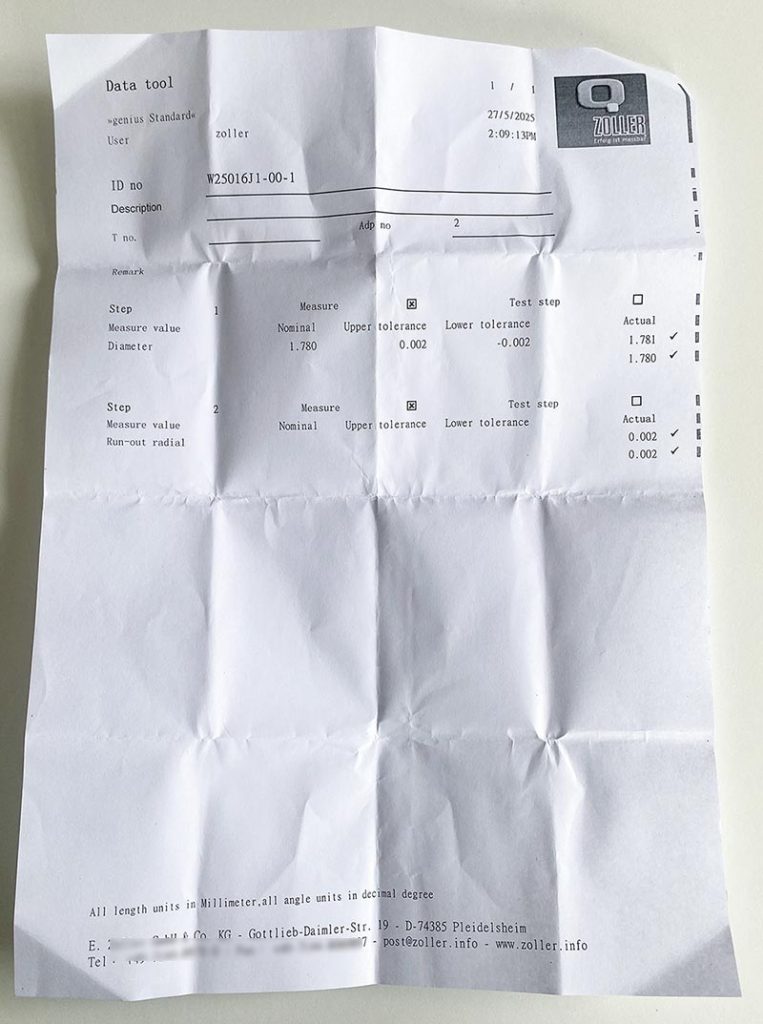

✅ Strict Quality Inspection System

- Final inspection conducted in temperature-controlled cleanroom environments;

- All products inspected using Coordinate Measuring Machines (CMM) and laser interferometers;

- Provided individual inspection reports (IPQC/FQC) for full traceability.

📊 Application Results: Breaking Industry Limits and Earning Customer Trust

After real-world testing by the client, the reamer performed exceptionally well:

| Test Item | Client Requirement | Actual Performance |

|---|---|---|

| Hole Diameter Tolerance | ±0.002 mm | Stably at ±0.0015 mm |

| Surface Roughness | Ra ≤ 0.4 μm | Ra = 0.35 μm |

| Tool Life | ≥1,000 holes | Achieved ≥1,800 holes |

| Machining Efficiency | —— | Processing time per piece reduced by 20% |

💬 Customer Feedback

“The performance of this reamer exceeded our expectations! Maintaining stable machining within such tight tolerances truly reflects the professionalism of SDFTools. It has not only reduced rework rates but also improved the overall production line stability.”

— European Semiconductor Equipment Manufacturer

🔍 Technical Highlights Summary

| Highlight | Description |

|---|---|

| Ultra-High Precision | Achieves ±0.002mm (±2μm) tolerance, meeting extreme precision machining needs |

| Multi-Specification Adaptability | Offers customization for D1.78, D0.64, and D1.307 mini-reamers |

| Strong Material Compatibility | Suitable for stainless steel, titanium alloy, and heat-resistant alloys |

| Excellent Surface Quality | Ra value below 0.2μm, significantly improving assembly accuracy and lifespan |

| Comprehensive Inspection System | Equipped with CMM, microscope, and laser detection throughout the process |

🏆 Why Choose SDFTools?

✅ Advanced Equipment Support

Equipped with Swiss precision grinders, laser interferometers, coordinate measuring machines, and other top-tier equipment to ensure every product is measurable, controllable, and repeatable.

✅ Rigorous Process Management

From drawing analysis, process planning, trial production verification to batch delivery, we strictly follow the ISO 9001 quality management system and provide complete inspection records.

✅ Rapid Response and Technical Support

We can complete preliminary design proposals within 72 hours, support global customization delivery, and offer one-on-one process optimization advice.

✅ Broad Applicability Across Industries

- ✈️ Aerospace: Engine precision assembly holes

- 💻 Semiconductor Equipment: Wafer alignment systems

- 🏥 Medical Devices: Implant connection holes

- 🔭 Optical Instruments: Lens mount installation holes

📢 Conclusion: Bringing Every Cut Closer to Perfection

The ±0.002 mm tolerance isn’t just a number—it represents SDFTools’ commitment to ultimate precision and quality assurance. We are always committed to putting customer needs at the center, leveraging advanced technology and professional services to continuously deliver efficient, stable, and energy-saving customized tooling solutions to customers around the world.

If you’re looking for a tooling partner capable of sub-micron precision, feel free to contact us anytime!

📩 [Get Your Free Custom Quote]

📞 WhatsApp: +65 89420188 / WeChat: +8618971569567

🌐 www.sdftools.com

📧 Email: sdfgroup@sdftools.com

🔗 LinkedIn: Shengdefu Precision Tools Co., Ltd