Understanding the Differences and Applications of These Key Thread Standards

When it comes to sealing threaded connections, NPT (National Pipe Taper) and BSPT (British Standard Pipe Taper) are two of the most widely used standards. Both are designed for sealing applications but have distinct characteristics that make them suitable for different environments. Let’s break it down:

Key Features of NPT and BSPT Threads

✅ NPT (National Pipe Taper) :

- Taper Design : 1:16 taper.

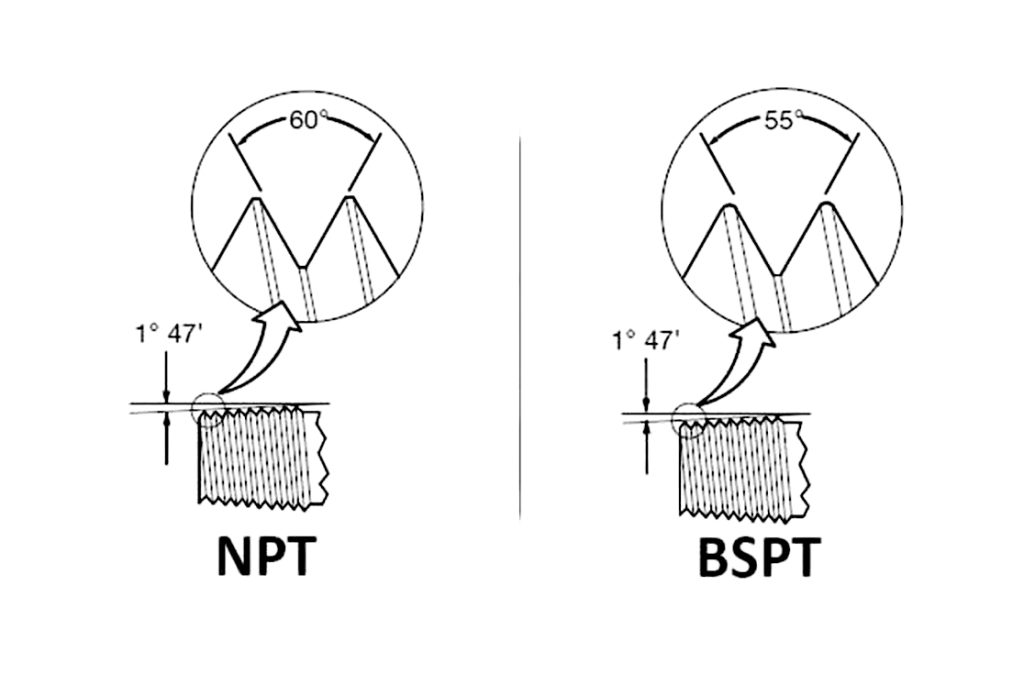

- Thread Angle : 60°.

- Sealing Mechanism : Relies on a metal-to-metal seal created by tightening. Often requires thread sealant (e.g., Teflon tape) for enhanced sealing.

- Applications : Commonly used in high-pressure, high-temperature, or corrosive fluid systems such as oil & gas, chemical processing, and fire protection systems—especially in North America.

✅ BSPT (British Standard Pipe Taper) :

- Taper Design : 1:16 taper.

- Thread Angle : 55°.

- Sealing Mechanism : Forms a tight metal-to-metal seal with uniform contact across threads. Often used with sealants to ensure leak-free performance.

- Applications : Widely adopted in water supply, gas pipelines, and hydraulic systems—especially in Europe, the UK, and Commonwealth countries.

Key Differences Between NPT and BSPT

1️⃣ Thread Angle :

- NPT uses a 60° thread angle , providing higher sealing pressure during tightening.

- BSPT uses a 55° thread angle , offering more uniform contact across threads.

2️⃣ Geographical Usage :

- NPT dominates in North America .

- BSPT is preferred in Europe, the UK, and Commonwealth nations .

3️⃣ Sealing Performance :

- NPT excels in high-pressure, high-temperature, or corrosive environments .

- BSPT shines in general fluid transfer applications like water and gas pipelines.

4️⃣ Compatibility :

- BSPT’s standardized design ensures better compatibility between manufacturers.

- NPT is less standardized globally but remains dominant in its regions of use.

Choosing the Right Tool for Machining NPT and BSPT Threads

When machining these tapered threads, full-profile thread milling cutters are often the tool of choice due to their rigidity and ability to achieve high surface finishes.

⚠️ Important Note :

Even though NPT and BSPT may appear similar (e.g., 1/2-14), their thread angles differ (60° vs. 55°). Always verify the thread standard before selecting a tool to avoid costly errors.

Which Is Better: NPT or BSPT?

There’s no definitive winner—it depends on your application:

- Use NPT for high-pressure, high-temperature, or corrosive environments.

- Choose BSPT for general fluid transfer systems requiring broader compatibility.

Both standards excel in their respective domains, ensuring safe, reliable, and efficient operations when applied correctly.

📍 Need Help Selecting the Right Thread Standard or Tools?

At SDFTools, we specialize in precision cutting tools for NPT, BSPT, and other threading applications. Let us help you optimize your machining processes.

💬 Questions? Reach Out Today!

#NPT #BSPT #ThreadStandards #CNCMachining #ManufacturingSolutions