SDF Precision Thread Milling:Your End-to-End Solution

From Stock to Bespoke - Conquer Any Threading Challenge with SDF’s Total Tooling System

Full-Spectrum Stock

Never delay production for thread tools again: M1 medical screws to M48 aerospace threads in ready-to-ship arsenal

Beyond Standards

When standard threads can’t solve your puzzle: Left-hand? Variable pitch? 55° compound angle? We engineer possibilities

Total Machining Solution

From tooling design to cost-per-part

optimization - delivering seamlessly integrated cutting solutions

Committed!

Always deliver more than expected.

Born from Singapore’s STAMFORD Group (est. 1998), Shengdefu Precision Tools (SDF) integrates global R&D with precision manufacturing. Anchored in Wuhan as our production hub and supported by Guangzhou’s export center, we deliver thread milling cutters and carbide tools to 1,276 manufacturers across 16 countries.

Our Roots:

- Singapore Innovation: Core designs from 25 years of cutting-edge tool engineering.

- Wuhan Manufacturing: 12 advanced CNC grinding machines ensure ISO 9001-certified quality.

- Global Agility: Standard tools ship directly from Guangzhou DHL保税仓, non-standard orders fulfilled in 5 days.

What improvements did we make to thread mills?

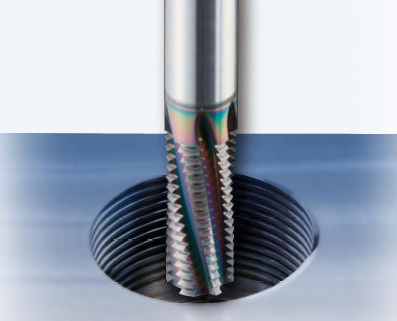

Material Chipping Crusher

Frequent chipping in stainless/titanium? SDF’s PM-HSS with nano-coating boosts impact resistance 200%, cutting 304SS threads over 300 pcs

Precision Tier System

Overspending on over-qualified tools? 3-tier solutions—Economy(±0.03mm), Performance(±0.015mm), Ultra-Precision(±0.005mm)—slash cost per part by 65%

Exotic Thread Hero

Long lead times for special threads? Modular body + replaceable heads deliver LH/taper/variable-pitch threads in 7 days at 40% less cos

Chatter Terminator

Vibration marks in deep threading? Anti-chatter geometry + damped holders ensure Ra0.8μm on L/D=8:1 parts

Thread Mills Ready to Ship: Performance to Precision, Instantly

3-Tier Excellence: Economy → Performance → Precision-Grade

Mill any pitch – inch or metric – with our impressive selection of Thread Mill Cutters. Available in Single Form, Multi-Form, Tri-Form, and Thread Relief. Many of these tools mill right hand and left hand threads and can cut internal and external 60° UN threads in many materials, including hardened steels.

Per-Model Support for Thread Mills

Thread Mill Technical Support

Welcome to SDF Precision Tools Thread Milling Technical Support Hub.

This resource is designed to help you maximize thread milling operations through essential technical guidance and best practices. Here you will find:

✓ Comprehensive speed & feed charts

✓ Application-specific guides for performance optimization

✓ Practical setup and calculation tips for precision & efficiency

Whether you’re new to thread milling or seeking process refinement, our support materials will assist you at every stage. For further assistance:

➤ Visit our social media channels

➤ Explore latest thread milling webinars

Speed and Feed Chart

When machining materials with an unfavorable length-to-diameter ratio, coarse thread pitches, or hard materials, you may need to use more radial depth passes than indicated on the speed and feed chart.

| Material | HB/Rc | Speed(SFM) Uncoated | Speed(SFM) AlTiN+ | Feed(Inches per Tooth) Tool Diameter .032 – .056 | Feed(Inches per Tooth) Tool Diameter .059 – .090 | Feed(Inches per Tooth) Tool Diameter .100 – .190 | Feed(Inches per Tooth) Tool Diameter .200 – .350 | Feed(Inches per Tooth) Tool Diameter .370 – .595 | Feed(Inches per Tooth) Tool Diameter .600+ |

|---|---|---|---|---|---|---|---|---|---|

| Cast Iron | 160 HB | 100-220 | 200-425 | .0004-.001 | .0004-.0008 | .0004-.0014 | .0004-.002 | .0004-.0035 | .0004-.006 |

| Carbon Steel | 18 Rc | 100-200 | 190-425 | .0003-.001 | .0003-.0008 | .0003-.0014 | .0003-.002 | .0003-.002 | .0003-.006 |

| Alloy Steel | 20 Rc | 80-200 | 200-375 | .0003-.001 2 Passes | .0003-.0008 3 Passes | .0003-.0014 | .0003-.0024 | .0003-.0024 | .0003-.006 |

| Tool Steel | 20 Rc | 80-175 | 175-250 | .0003-.0004 2 Passes | .0003-.0005 3 Passes | .0003-.0005 | .0003-.0009 | .0003-.0009 | .0003-.004 |

| 300 Stainless Steel | 150 HB | 90-120 | 120-255 | .0003-.0005 2 Passes | .0003-.0006 3 Passes | .0003-.0007 | .0003-.002 | .0003-.002 | .0003-.0045 |

| 400 Stainless Steel | 195 HB | 90-150 | 140-375 | .0003-.0005 2 Passes | .0003-.0006 3 Passes | .0003-.0007 | .0003-.002 | .0003-.002 | .0003-.0045 |

| High Temp Alloy (Ni & Co Base) | 20 Rc | 50-125 | 100-125 | .0003-.0004 3 Passes | .0003-.00045 3 Passes | .0003-.0005 2 Passes | .0003-.0009 | .0003-.0009 | .0003-.004 |

| Titanium | 25 Rc | 50-130 | 100-170 | .0003-.0004 3 Passes | .0003-.00045 3 Passes | .0003-.001 2 Passes | .0003-.0009 | .0003-.0009 | .0003-.003 |

| Heat Treated Alloys (38-45Rc) | 40 Rc | 50-90 | 90-150 | .0003-.0004 3 Passes | .0003-.00045 3 Passes | .0003-.0005 2 Passes | .0003-.0008 | .0003-.0008 | .0003-.0025 |

| Aluminum | 100 HB | 100-800 | 100-1200 | .0005-.0015 | .0005-.002 | .0005-.0025 | .0005-.003 | .0005-.003 | .0005-.009 |

| Brass, Zinc | 80 HB | 200-350 | 200-750 | .0005-.0015 | .0005-.0025 | .0005-.0025 | .0005-.003 | .0005-.003 | .0005-.009 |

Partners

Take action now.

✓ Core product portfolios

✓ Custom tooling solutions

✓ Distributor programs

✓ Volume-based pricing

Direct engineer support within 24h – Zero formality